Winding method for preventing flat roll of hot rolled steel strip

A technology for hot-rolled steel and flat coils, which is applied in the field of hot-rolled steel strip coiling and can solve problems such as flat coils

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

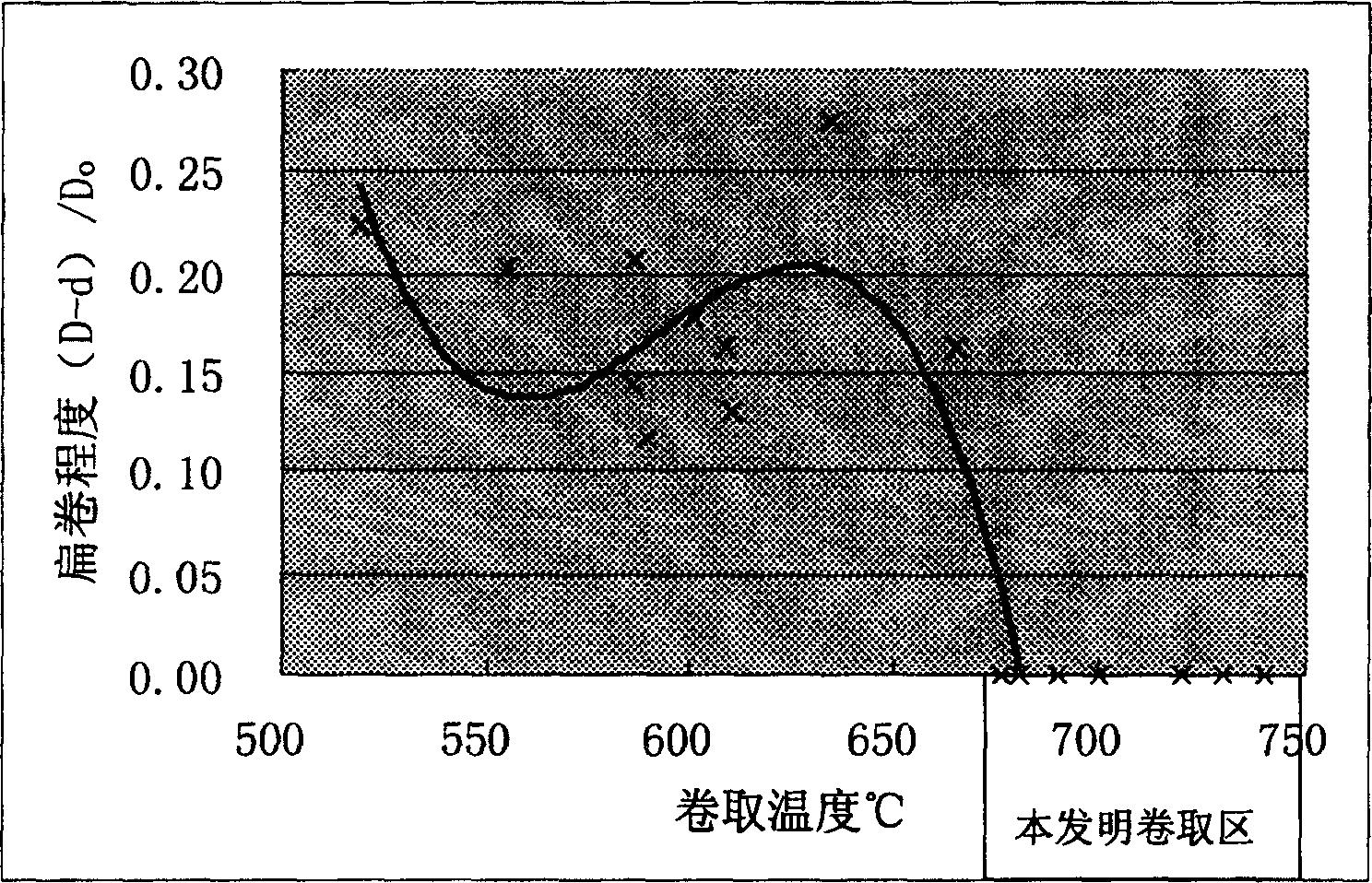

Problems solved by technology

Method used

Image

Examples

Embodiment 1

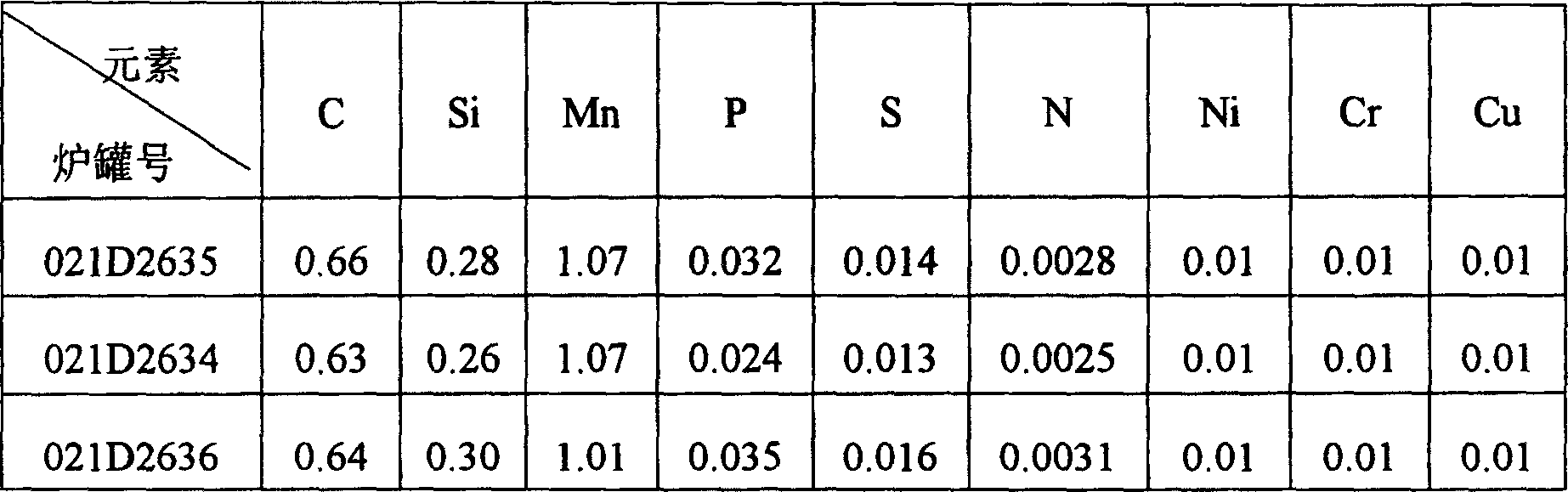

[0011] Embodiment 1: with production chemical composition (Wt%) C: 0.62~0.70; Si: 0.17~0.37; Mn: 0.90~1.20; P≤0.035; S≤0.040; Cr≤0.25; Ni≤0.25; Cu≤0.25 ; The rest is Fe and unavoidable impurities 65Mn thin coil as an example, the chemical composition of some furnace numbers is shown in Table 1, and the specifications of the rolled coil are shown in Table 2. The thinnest specification is 2.0mm, and the thickest specification is 4.0mm.

[0012] Table 1: 65Mn Coil Chemical Composition Wt%

[0013]

[0014]

Volume number

specification, mm

coiling temperature

℃

flat roll case

Volume number

specification, mm

coiling temperature

℃

flat roll case

6179502010

3.0×1250

609

flat roll

6223502010

4.0×1200

724

none

6179502020

3.0×1250

680

none

6223502020

4.0×1200

689

none

...

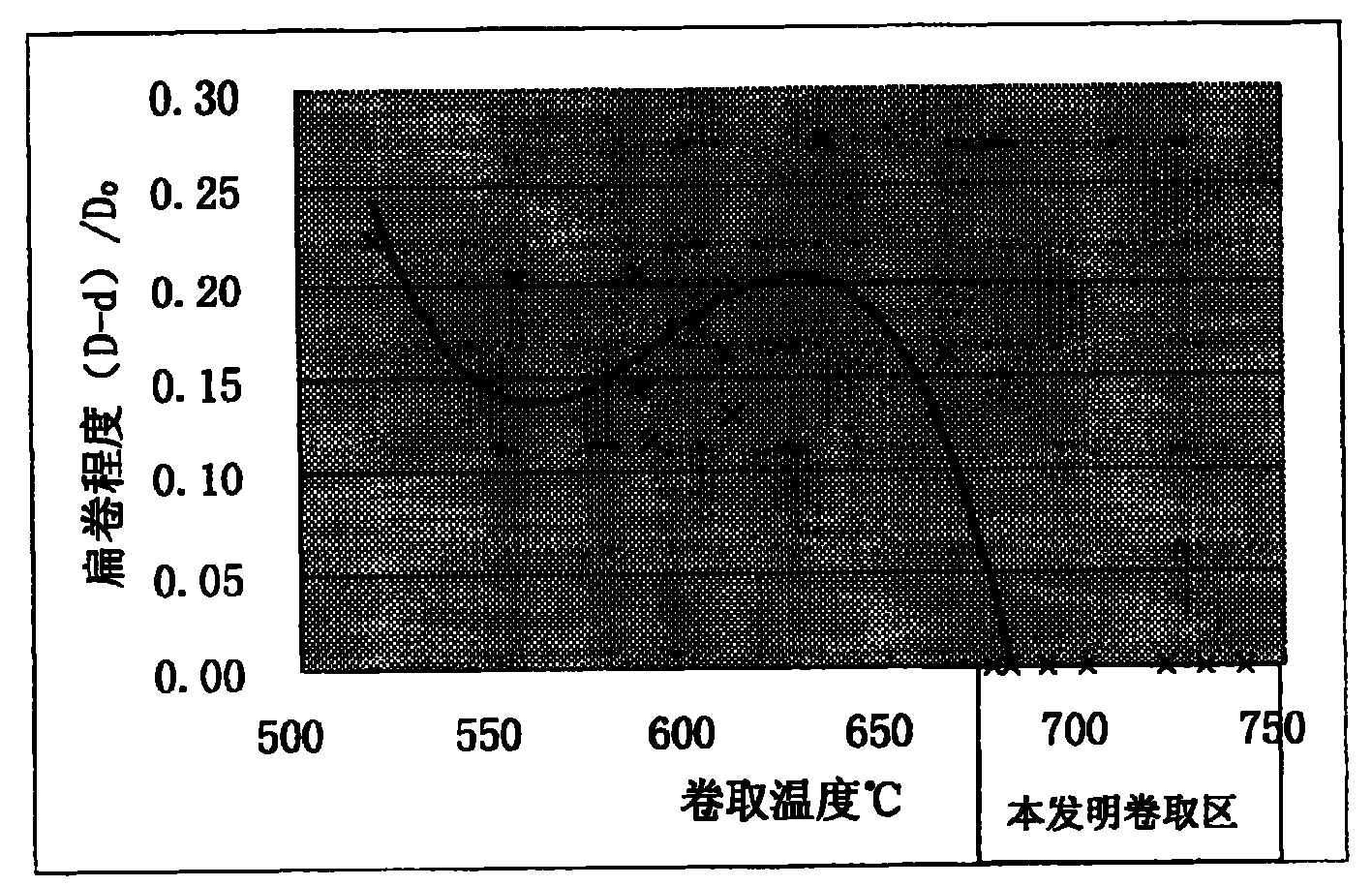

Embodiment 2

[0017] Embodiment 2: with production chemical composition (Wt%) C: 0.26~0.34; Si: 0.20~0.40; Mn: 0.40~0.70; P≤0.040; S≤0.040; Cu≤0.30; : 0.15~0.25 30CrMo thin coils with Fe and unavoidable impurities are taken as an example. The thinnest specification is 2.15mm, and the thickest specification is 4.40mm.

[0018] Table 3: 30CrMo Coil Chemical Composition Wt%

[0019]

[0020] Furnace No.

[0021] From the steel manual, the phase transition temperature A of 30CrMo steel is r1 According to the coiling method of the present invention, the coiling temperature is controlled within the range of 683°C to 753°C, and the optimum coiling temperature is 703 to 723°C. It can be seen from the data in Table 4 that flat coiling does not occur when the coiling temperature is controlled within the range of 683°C to 753°C, but flat coiling occurs when the coiling temperature is lower than 683°C.

Embodiment 3

[0022] Embodiment 3: with production chemical composition (Wt%) C: 0.42~0.50; Si: 0.17~0.37; Mn: 0.50~0.80; P≤0.035; S≤0.040; Cr≤0.25; Ni≤0.25; Cu≤0.25 ; The rest is 45% of Fe and unavoidable impurities # Take thin coils as an example, the chemical composition of some furnace numbers is shown in Table 5, and the specifications, coiling temperature and flat coils of the rolled coils are shown in Table 6. The thinnest specification is 2.0mm and the thickest is 6.0mm.

[0023] Table 5: 45 # Coil Chemical Composition Wt%

[0024]

[0025] Coil No.

Rolling specifications (thick mm)

Average coiling temperature (℃)

flat roll case

7380102100

2.0×1000

668

flat roll

6410603030

3.0×1300

666

flat roll

6410604010

3.0×1250

654

flat roll

6389801020

2.0×1000

720

none

6410303010

6.0×1250

740

none

6410304010

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| phase transition temperature | aaaaa | aaaaa |

| phase transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com