Air conditioner

A technology for air conditioners and motors, applied in synchronous machines, refrigerators, compressors, etc., can solve the problems of weak excitation current, reduced heating capacity, and increased induced electromotive force of permanent magnets, and achieve the effect of changing the effective magnetic flux.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Embodiments of the present invention will be described below.

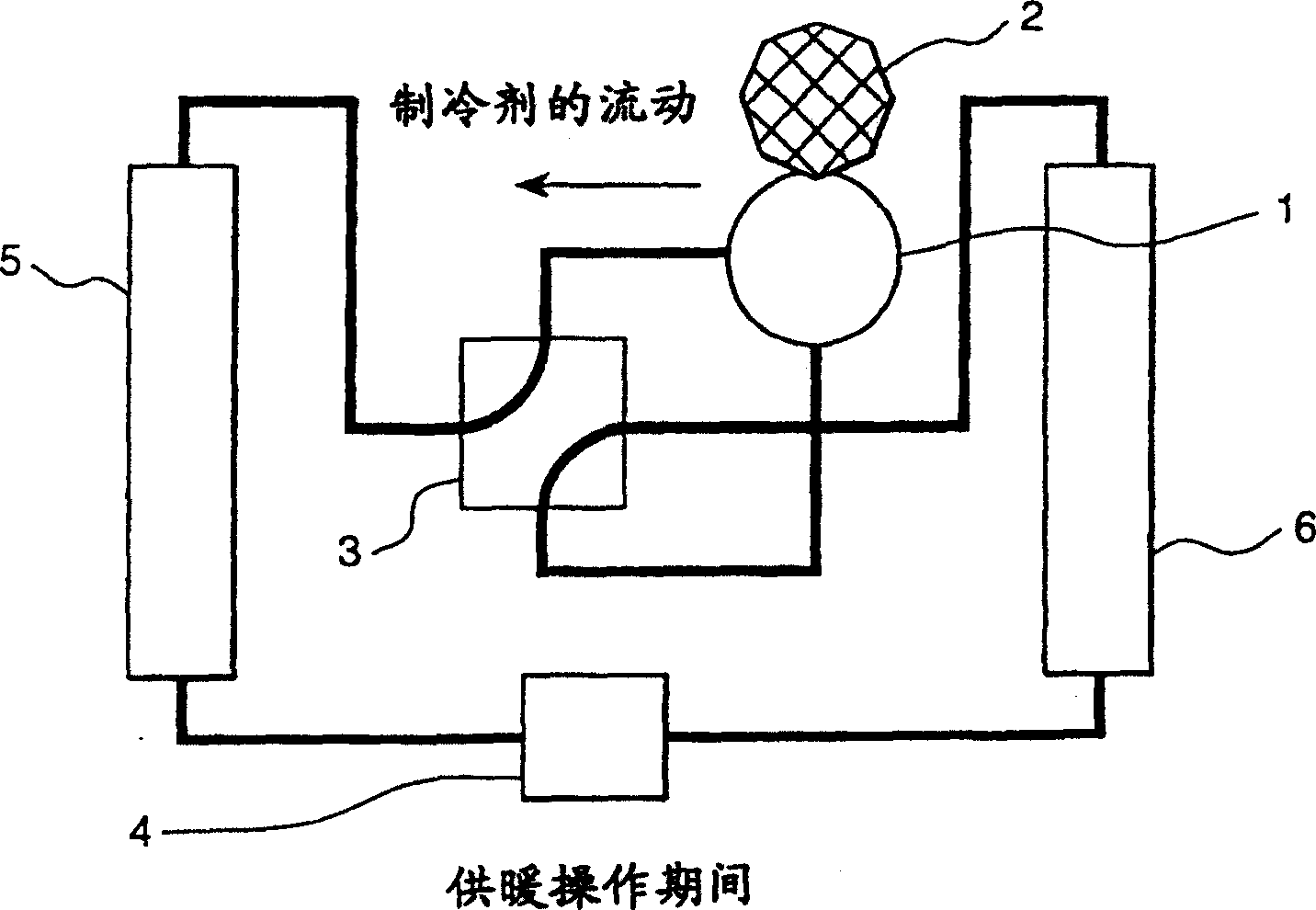

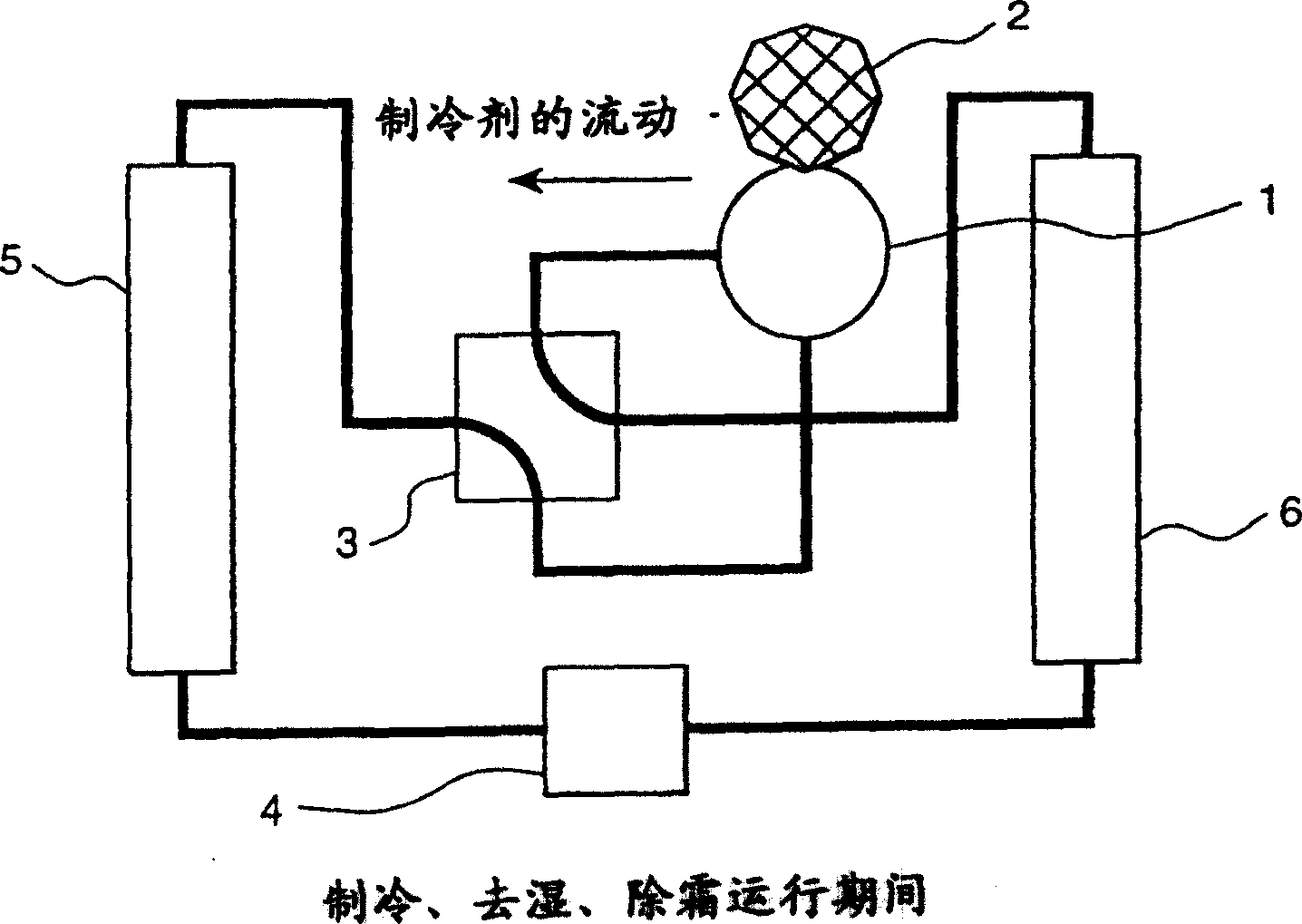

[0027] Fig. 1 is a schematic diagram showing a refrigeration cycle of an embodiment having a permanent magnet type synchronous motor.

[0028] FIG. 1( a ) shows a refrigeration cycle (flow of refrigerant) during a heating operation, and FIG. 1( b ) shows a refrigeration cycle during a cooling, dehumidification, and defrosting operation.

[0029] The air conditioner shown in Fig. 1 has the basic structure of refrigeration cycle, and this structure is by the electric motor 2 of compressor 1, the power source of compressor, a four-way valve 3, an expansion valve 4, an indoor heat exchanger 5 and an outdoor The heat exchanger 6 is configured to control the flow rate of the refrigerant cycle in the refrigeration cycle by changing the rotational speed of the motor and the opening degree of the electric expansion valve.

[0030] First, the refrigeration cycle during the heating operation shown in Fig. 1(a) will b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com