Plastic movable guide device for transmission

A transmission device and guide technology, applied in the direction of transmission device, belt/chain/gear, mechanical equipment, etc., can solve the problems of deformation of reinforcement plate, reduction of assembly capacity, increase of production cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

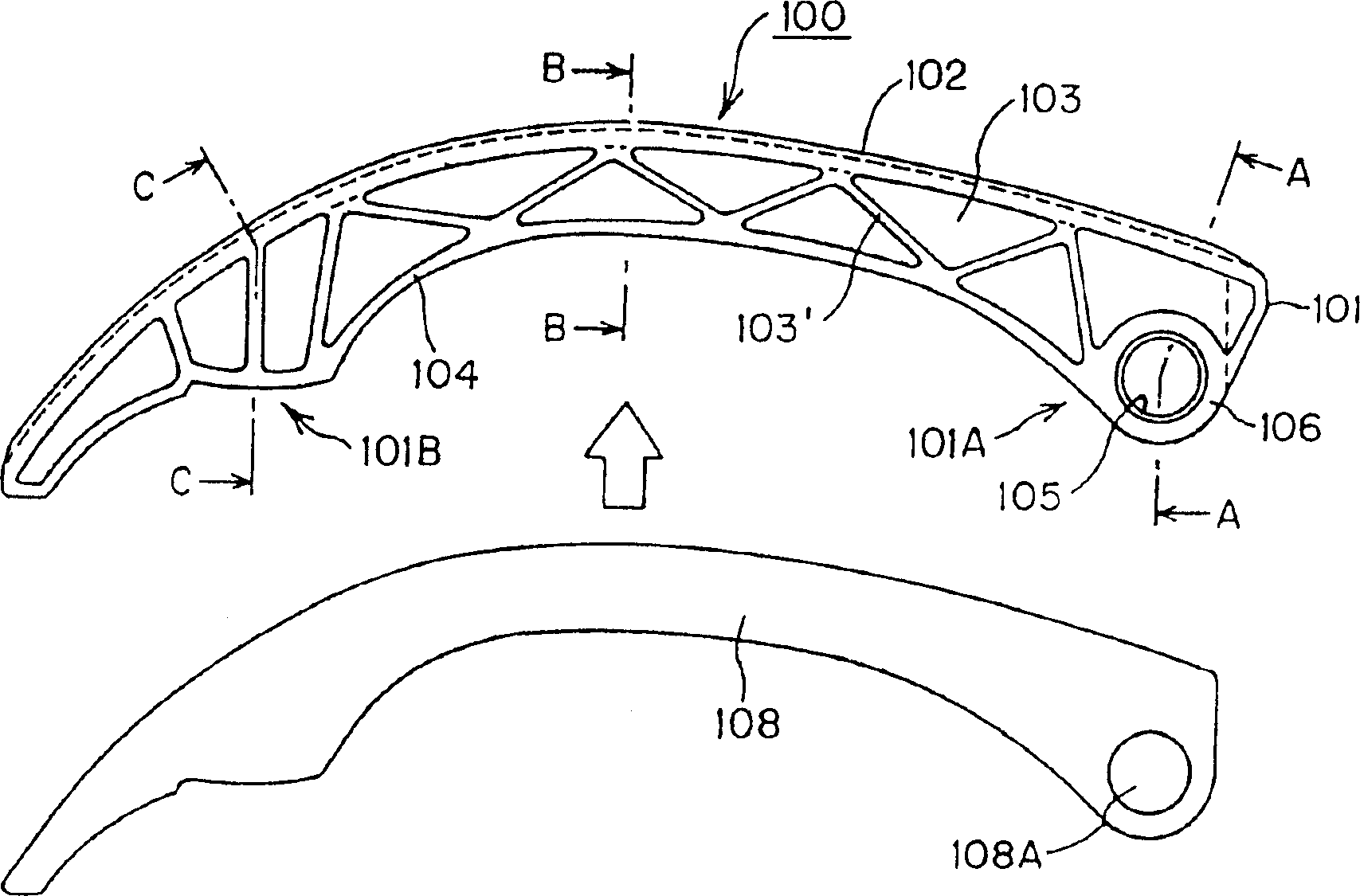

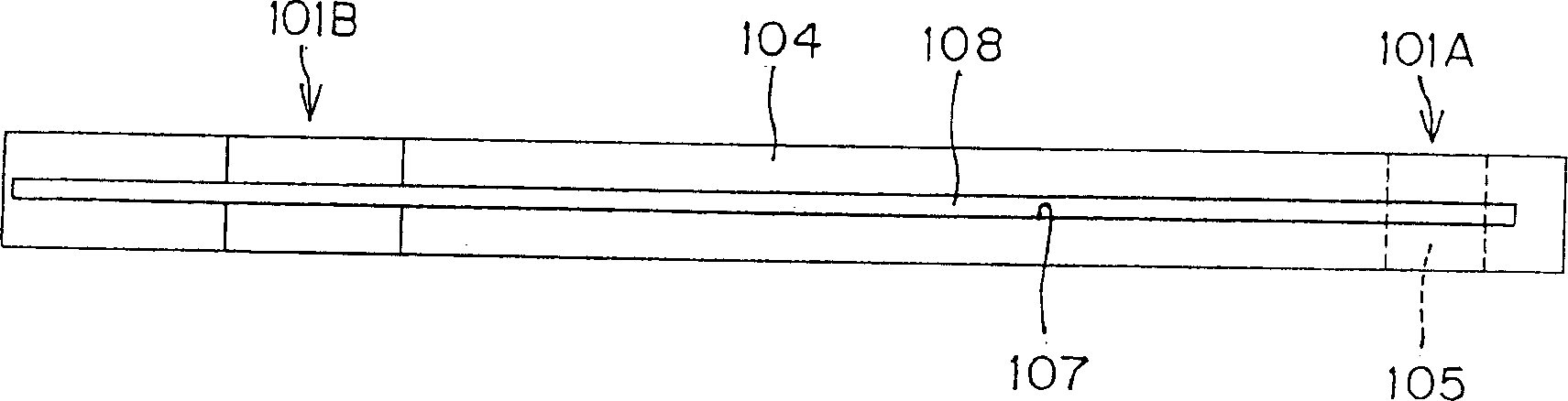

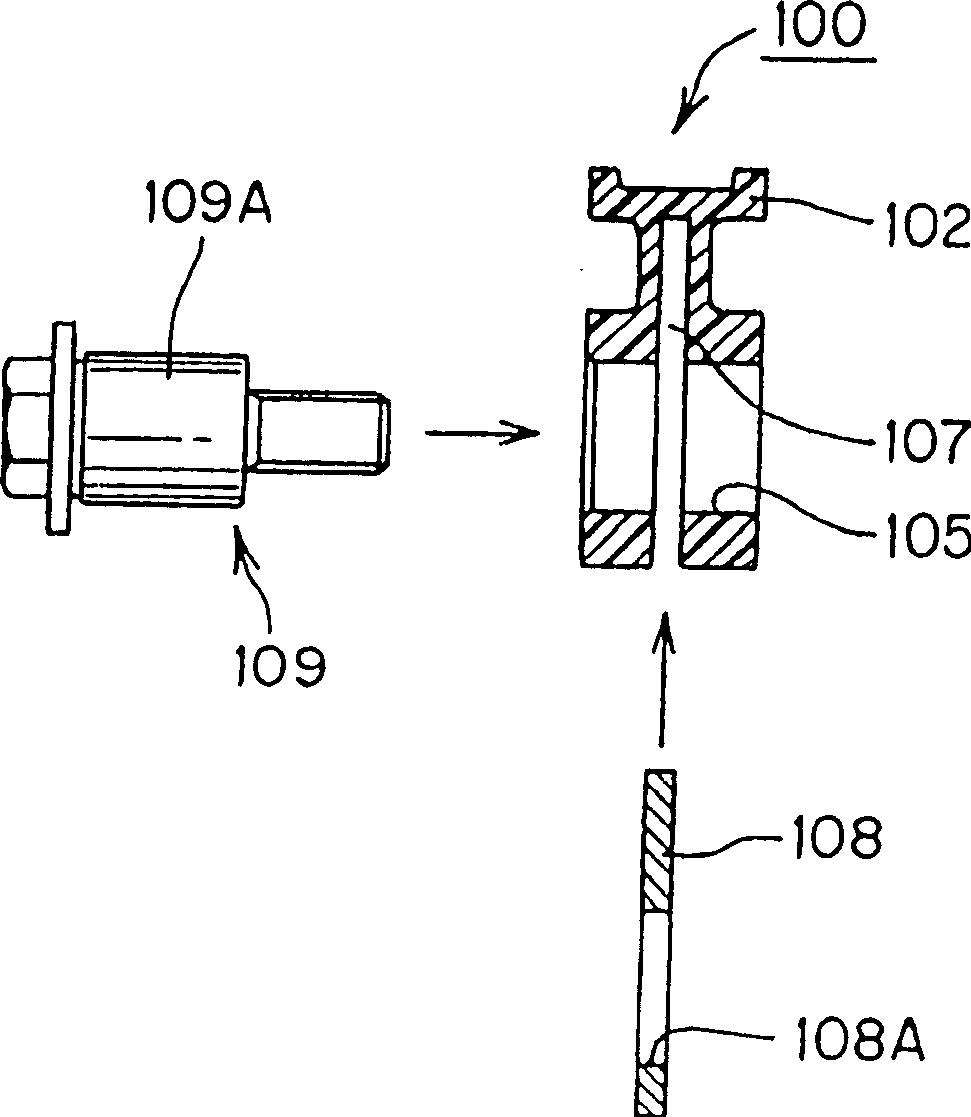

[0027] The following will refer to Figures 1 to 5 An embodiment of the present invention will be described. figure 1 The assembled state of a plastic movable guide 100 used in a chain drive is shown. The movable guide 100 is formed by inserting a reinforcing plate 108 into the guide main body 101 in the direction of the arrow. figure 2 yes figure 1 Bottom side plan view of the plastic movable guide shown. image 3 is along figure 1 Sectional view of midline A-A. Figure 4 is along figure 1 Sectional view of midline B-B. in addition, Figure 5 is a cross-sectional view along the line C-C, wherein the plunger 110 and the figure 1 The plunger receiving portion 101B on the pivoting front end side of the plastic movable guide is shown in contact.

[0028] This guide main body 101 is a plastic main body integrally molded from synthetic resin, includes a support pad portion 102 with a sliding surface that is in sliding contact with the running chain on one surface sid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com