Electrodialysis of multivalent metal salts

A polyvalent metal salt, electrodialysis cell technology, applied in fermentation, membrane technology, chemical instruments and methods, etc., can solve problems such as high equipment capital costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

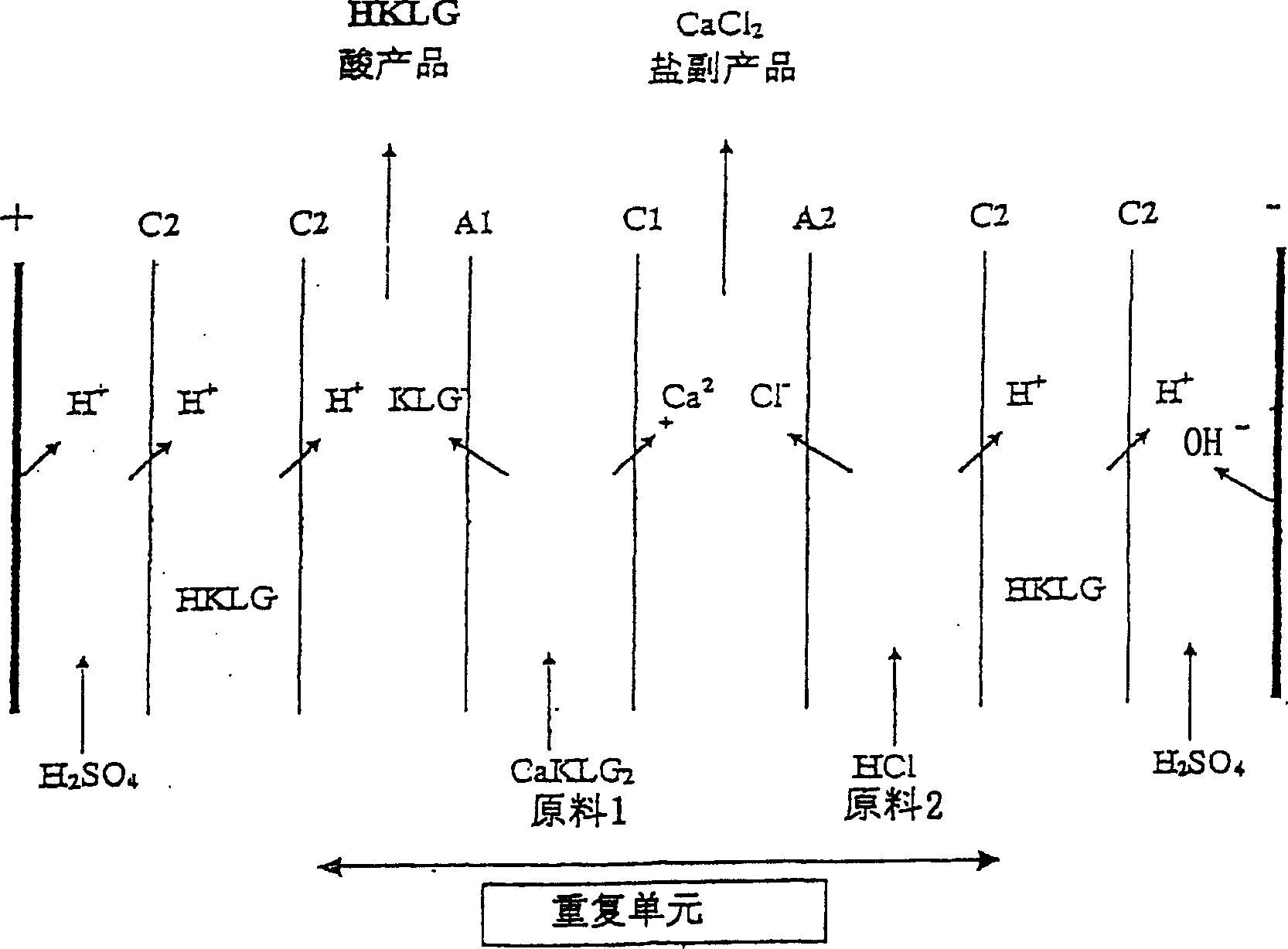

[0035] The recovery of KLG acid from KLG calcium in a four-compartment electrodialysis stack is illustrated as follows, wherein:

[0036] Produced as Ca(KLG) 2 The fermentation broth containing 12.7% KLG was microfiltered to remove small crystals and treated with activated carbon to remove color and contaminants. Nine 25L batches of this broth passed FuMA-Tech at pH 5.5 TM The first raw material compartment of an ED100 four-compartment laboratory electrodialysis cell equipped with a CaKLG for delivery 2 10 sets of Neosepta CMX-SB cationic and Neosepta AXE-01 anionic membranes, and 10 sets of Neosepta CMX-SB / Neosepta AXE-01 cationic and anionic membranes for HCl delivery. The metathesis pool corresponds to figure 1 pool. The unit area of the metathesis pool is 100cm per membrane 2 The active area, the gap between the membranes is 0.6mm. A constant approximately 0.4 molar aqueous solution of HCl was passed through the second compartment. Concentrated HCl was added to m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com