Apparatus for manufacturing molten pig iron and reduced iron by utilizing fluidized bed, and method therefor

A preparation device, fluidized bed technology, applied in the direction of process efficiency improvement, sustainable manufacturing/processing, climate sustainability, etc., can solve the problems of high equipment cost, complicated equipment, complicated operation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

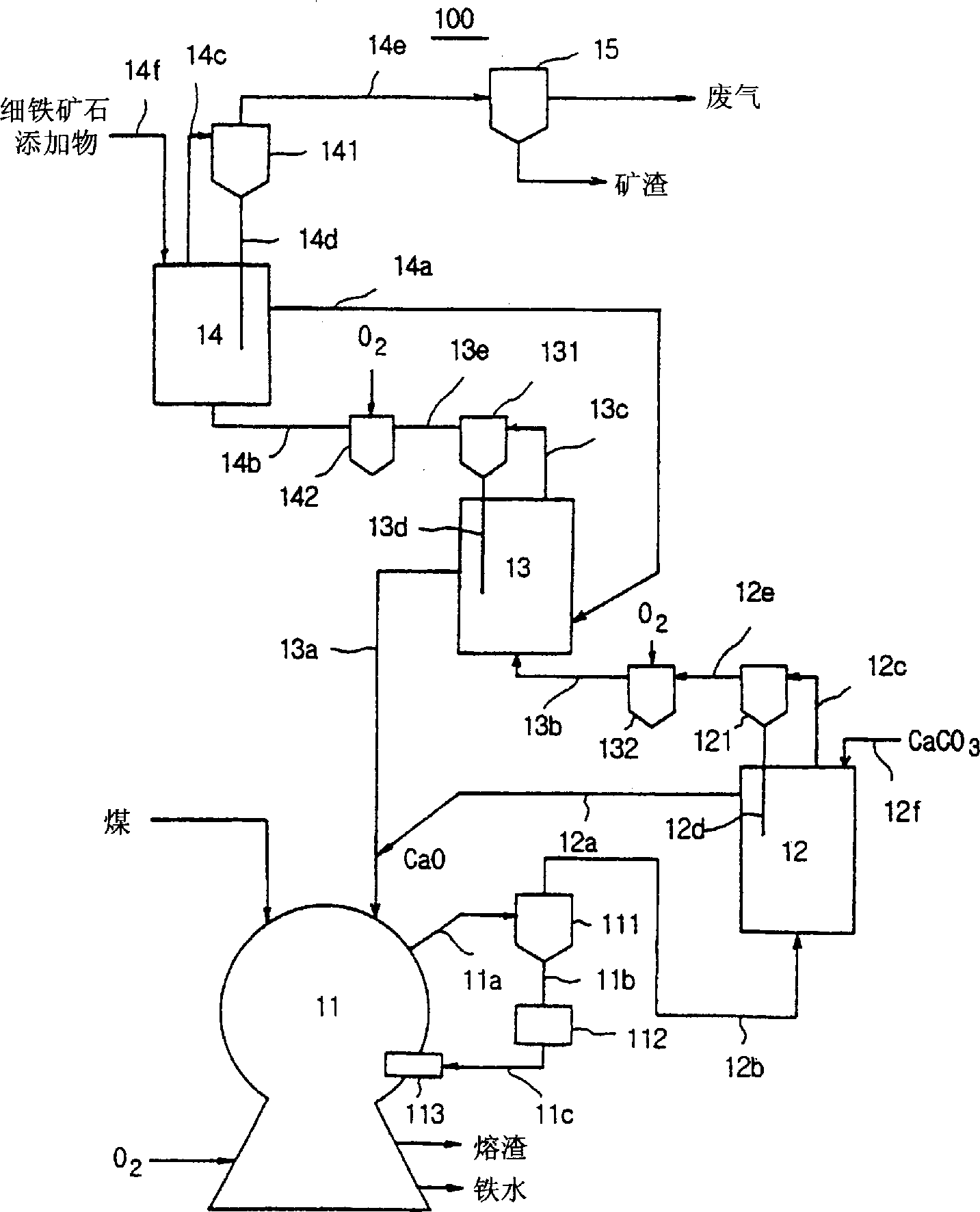

[0025] image 3 It is a schematic diagram of the molten iron preparation device of the present invention. Such as image 3 As shown, the molten iron preparation device 100 of the present invention includes: a melting and gasifying furnace 11 for gasifying coal and melting reduced iron ore; a third fluidized bed calciner 12 for utilizing the melting and gasifying furnace 11 to discharge The gas calcined limestone; the second fluidized bed reduction furnace 13, used for indirect reduction of fine iron ore; the first fluidized bed reduction furnace 14, used for preheating and pre-reducing fine iron ore; dust cyclone separator 111 , for sending the dust (separated from the reducing gas of the melter-gasifier 11) into the dust recirculation device 112, and supplying the waste gas (separated from the dust) to the third fluidized bed calciner 12; The melting burner 113 installed on the melting and gasifying furnace 11 is used to inject fine iron ore from the dust recirculation devi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com