Production technology of red yeast beer

A production method and technology of red yeast rice, which is applied in the direction of beer brewing, etc., to achieve the effect of pure and light taste, high nutritional value and bright color

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

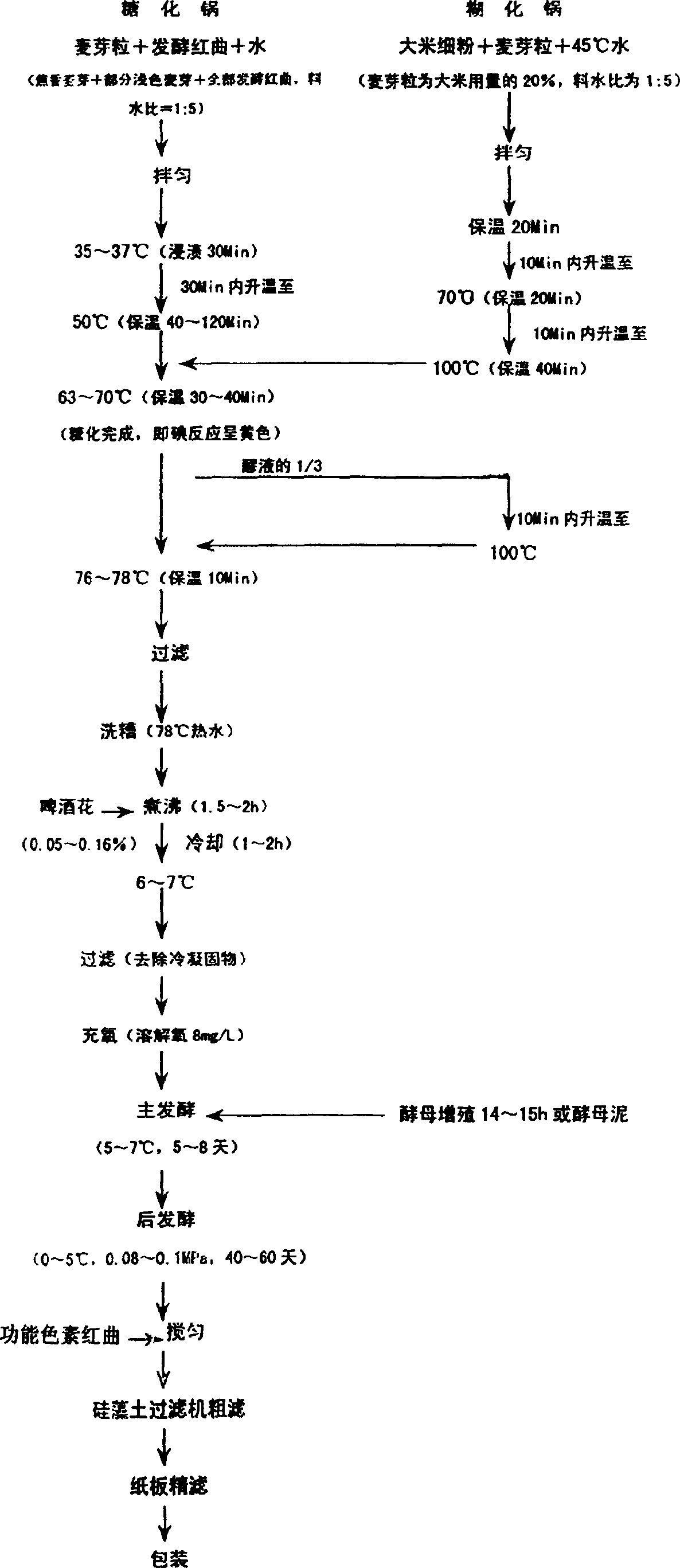

Method used

Image

Examples

Embodiment 1

[0019] Embodiment 1: red yeast rice beer, it is mainly made up of dry material and water, and dry material is made up of high-enzyme light-colored malt, black (burnt fragrance) malt, rice, fermented red yeast rice, and each component accounts for dry material gross weight percentage for:

[0020] High-enzyme light-colored malt 60, black (caramel) malt 10,

[0021] Rice 25, fermented red yeast rice 5;

[0022] The ratio of material to water is 1:5, the functional pigment red yeast rice is 0.05%-0.5% of the dry material weight, and the hops is 0.05-0.16% of the dry material weight.

[0023] Raw materials and quality requirements:

[0024] Fermented red yeast rice: color price ≥ 600U / g, quality conforms to GB4926-85 red yeast rice;

[0025] Malt: in line with QB1686-93 beer malt quality index;

[0026] Rice: in line with the quality index of GB1354-86 rice special or standard first;

[0027] Hops:

[0028] Moisture / % α-acid / % Color Odor

[0029] 8.5 6.5 Yellow-gree...

Embodiment 2

[0048] Embodiment 2: red koji beer, it is mainly made up of dry material and water, and dry material is made up of high-enzyme light-colored malt, black (burnt fragrance) malt, rice, fermented red yeast rice, and each component accounts for dry material gross weight percentage for:

[0049] High-enzyme light-colored malt 55, black (caramel) malt 12,

[0050] Rice 28, fermented red yeast rice 5;

[0051] The ratio of dry material to water is 1:4.5, the functional pigment red yeast rice is 0.05%-0.5% of the dry material weight, and the hops is 0.05-0.16% of the dry material weight.

[0052] Its production method is with embodiment 1.

Embodiment 3

[0053] Embodiment 3: red koji beer, it is mainly made up of dry material and water, and dry material is made up of high-enzyme light-colored malt, black (burnt fragrance) malt, rice, fermented red yeast rice, and each component accounts for dry material gross weight percentage for:

[0054] High-enzyme light-colored malt 65, black (caramel) malt 8,

[0055] Malt 23, fermented red yeast rice 4;

[0056] The ratio of dry material to water is 1:5.5, the functional pigment red yeast rice is 0.05%-0.5% of the dry material weight, and the hops is 0.05-0.16% of the dry material weight.

[0057] Its production method is with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com