Water vaporization method and device as well as medium frequency induced water vaporization method and device

A chemical device and water vapor technology, applied in steam generation methods, steam superheating, steam generation, etc., can solve the problems of low thermal efficiency, low pressure requirements for pressure vessels, and low power, so as to achieve high thermal efficiency, reduce workload, and reduce The effect of loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

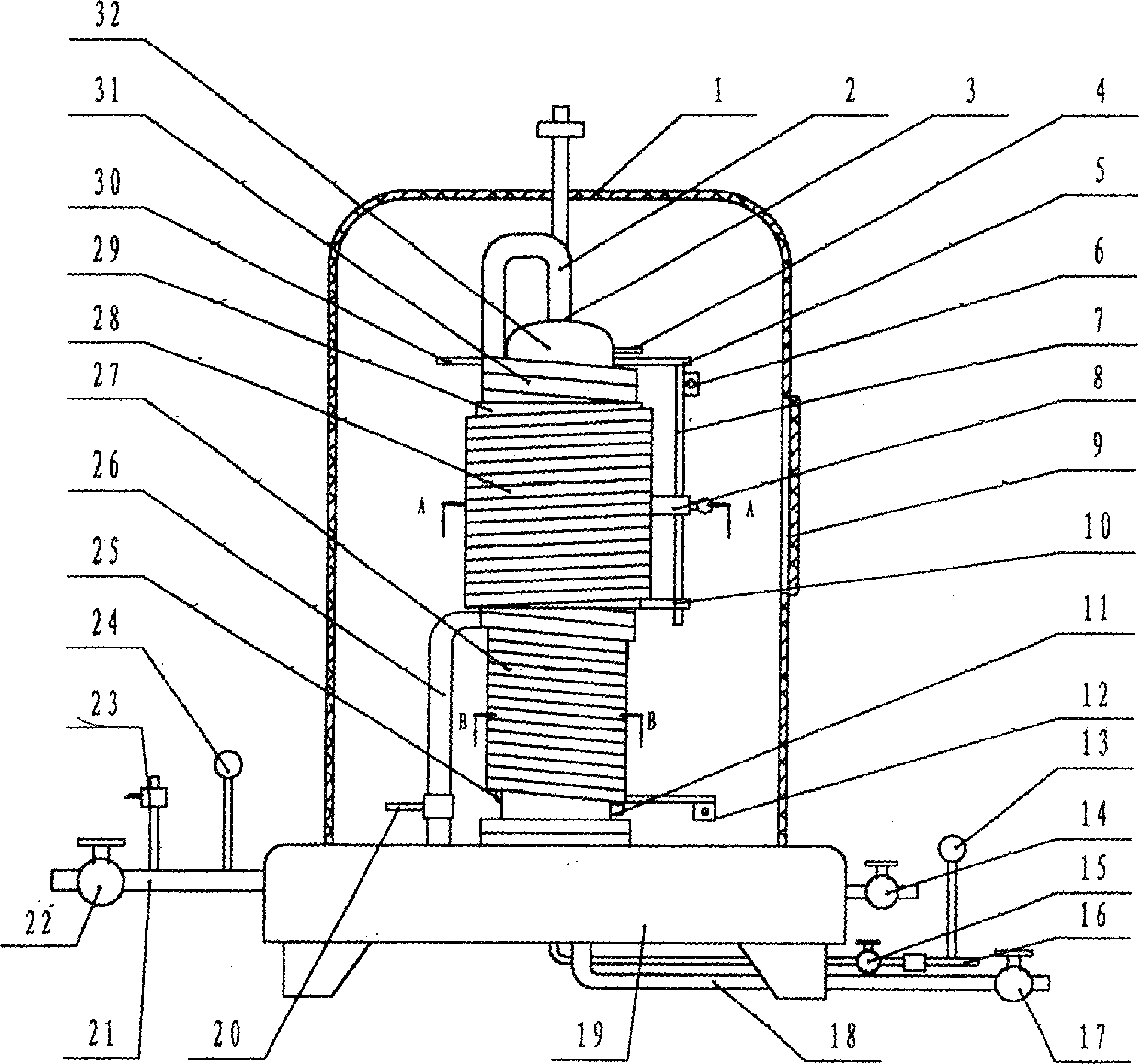

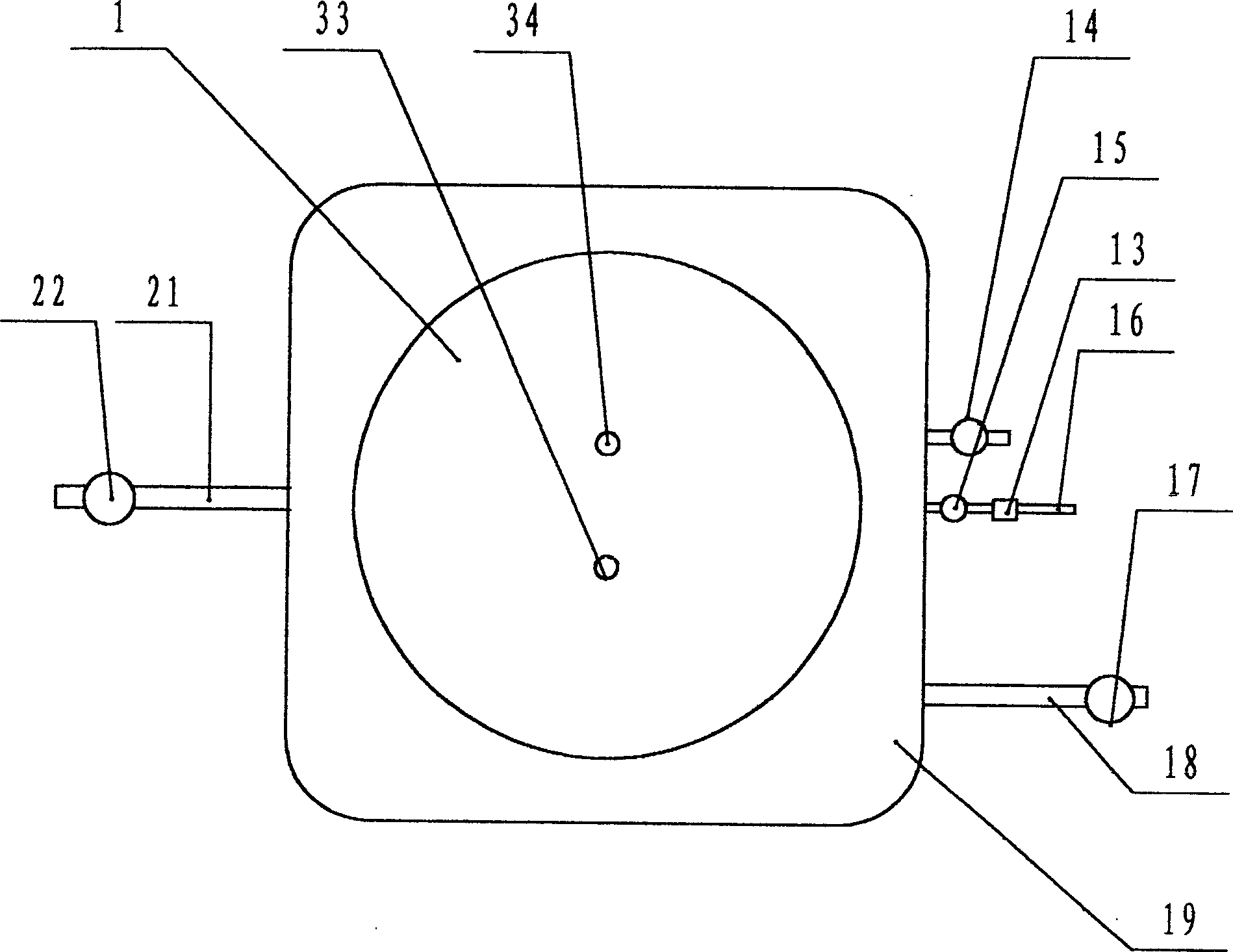

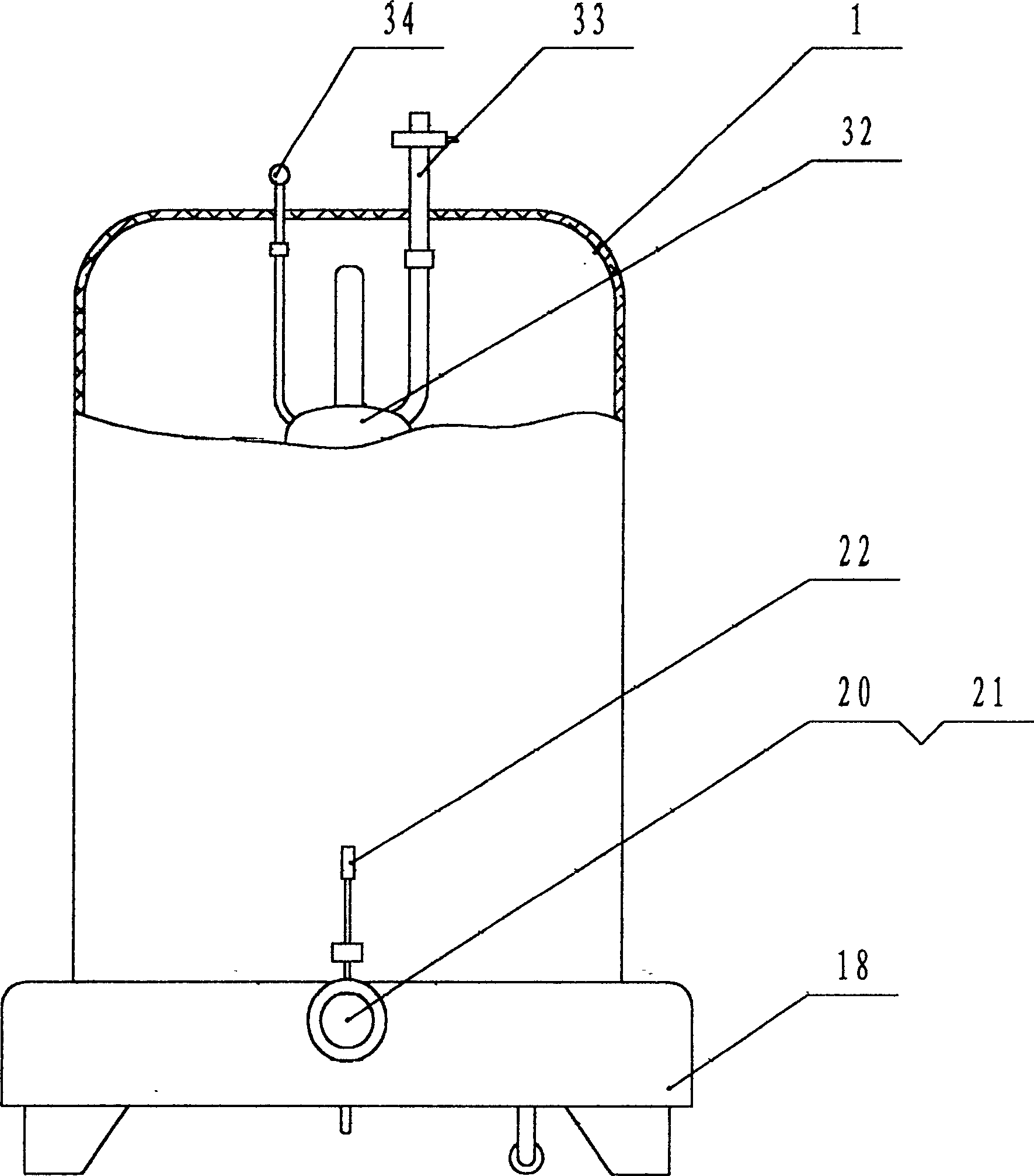

[0067] The structure and working principle of the electric energy water vaporization method and the electric energy water vaporization device of the present invention will be described in detail below in conjunction with the embodiments and accompanying drawings, but the present invention is not limited to the given embodiments.

[0068] by Figure 11 Illustrate the necessary steps of this electric energy water vaporization method, it is that the airtight cylinder shell 39 of steam generator 32 is heated to 165 ℃ with the airtight container of built-in spray nozzle 36 with heating furnace 55, and water is pumped with about 0.3Mpa The pressure is sprayed into atomized water droplets from the spray nozzle 36 through the spray water pipe 38 and sprayed onto the inner wall of the airtight cylindrical shell 39 so that the water is preheated and vaporized immediately, and then the water vapor is discharged from the steam pipe 2.

[0069] Embodiment 1 of the electric energy water vap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com