Process for preparing titanium silicon carbon ceramic powder

The technology of titanium silicon carbon and ceramic powder is applied in the field of preparation of ceramic powder, which can solve the problems of troublesome preparation process, increase preparation cost, different particle size and shape, etc., and achieve the effects of short preparation time, low cost and simple production process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

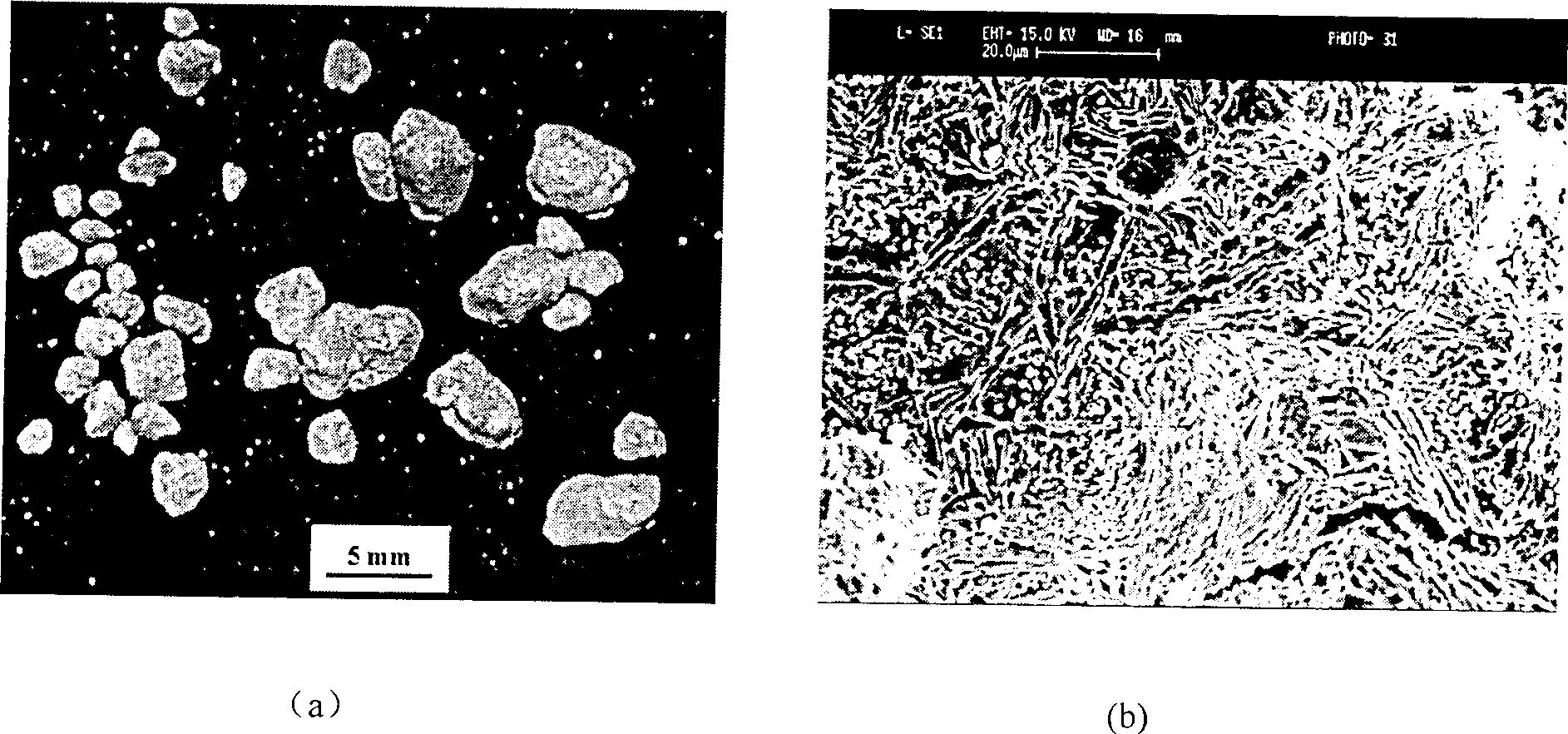

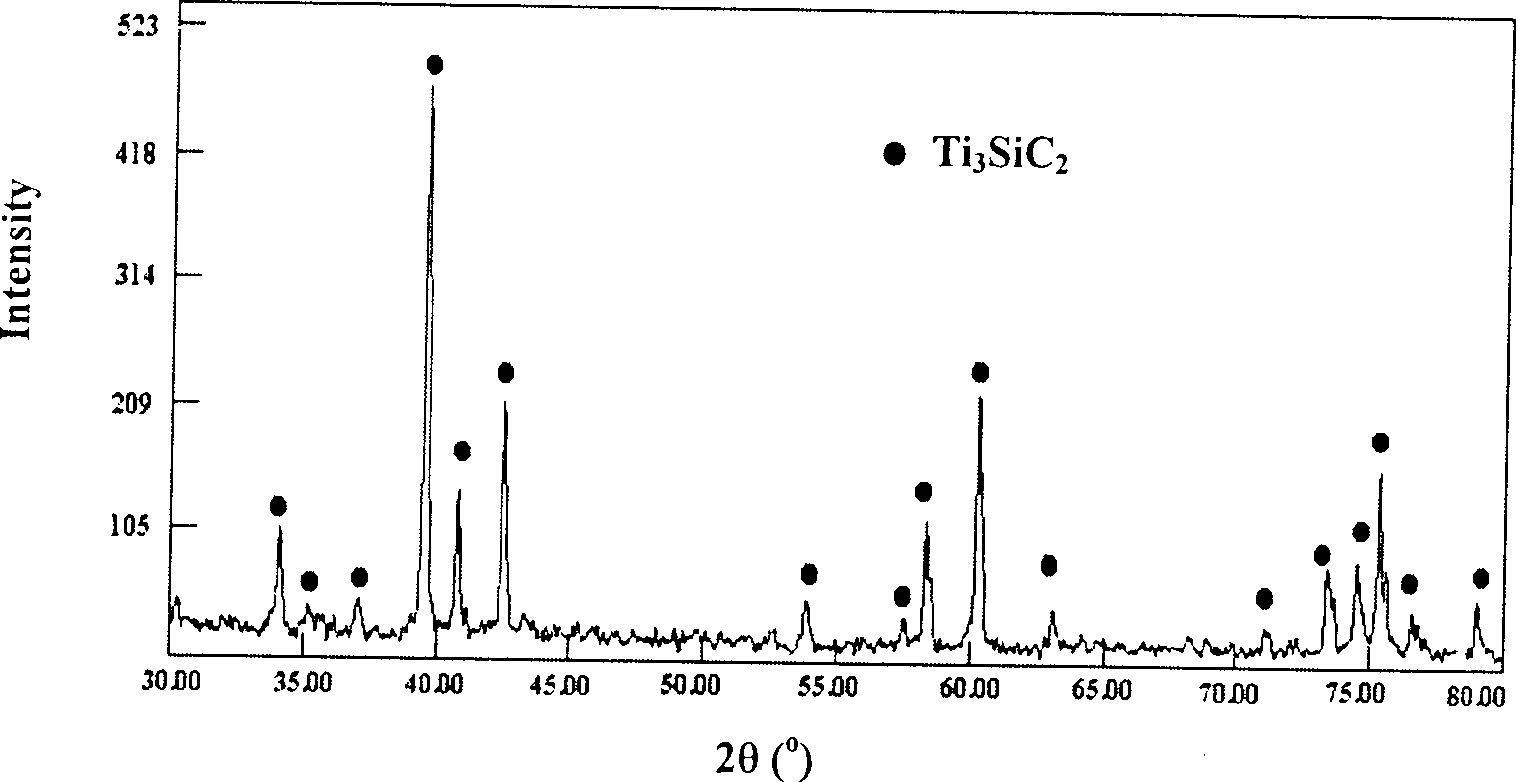

[0017] The average particle size is 48 μm, the titanium powder that is 99.14% in purity, the average particle size is 25 μm, the silicon powder that is 99.95% in purity and the graphite powder that is 45 μm in average particle size, and the purity is 99.8% three kinds of powders, by 3:1 : 2 molar ratio into the grinding tank. The volume of each stainless steel tank is 500ml, and the grinding tank is evacuated to 0.1Pa. The material of the grinding balls used is stainless steel, the weight ratio of the balls to the material is 20:1, the speed of the ball mill is 250r / min, and after 1.5 hours of ball milling, a large number of small particles with a size of about 5mm are formed. These small particles are mainly composed of a large number of rods or flakes. Ti 3 SiC 2 In addition, it also contains fine white spherical TiC particles and silicides, as shown in the accompanying drawings figure 1 (a) and (b). Mill these small particles in a ball mill for 1 to 2 hours, take out th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| Vickers hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com