Oil pumping apparatus of closed compressor

A compressor and airtight technology, which is applied to mechanical equipment, machines/engines, liquid variable capacity machines, etc., can solve the problems of inconvenient assembly operations, unsmooth upward pumping of lubricating oil 21, inaccuracy, etc., so as to improve work efficiency. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

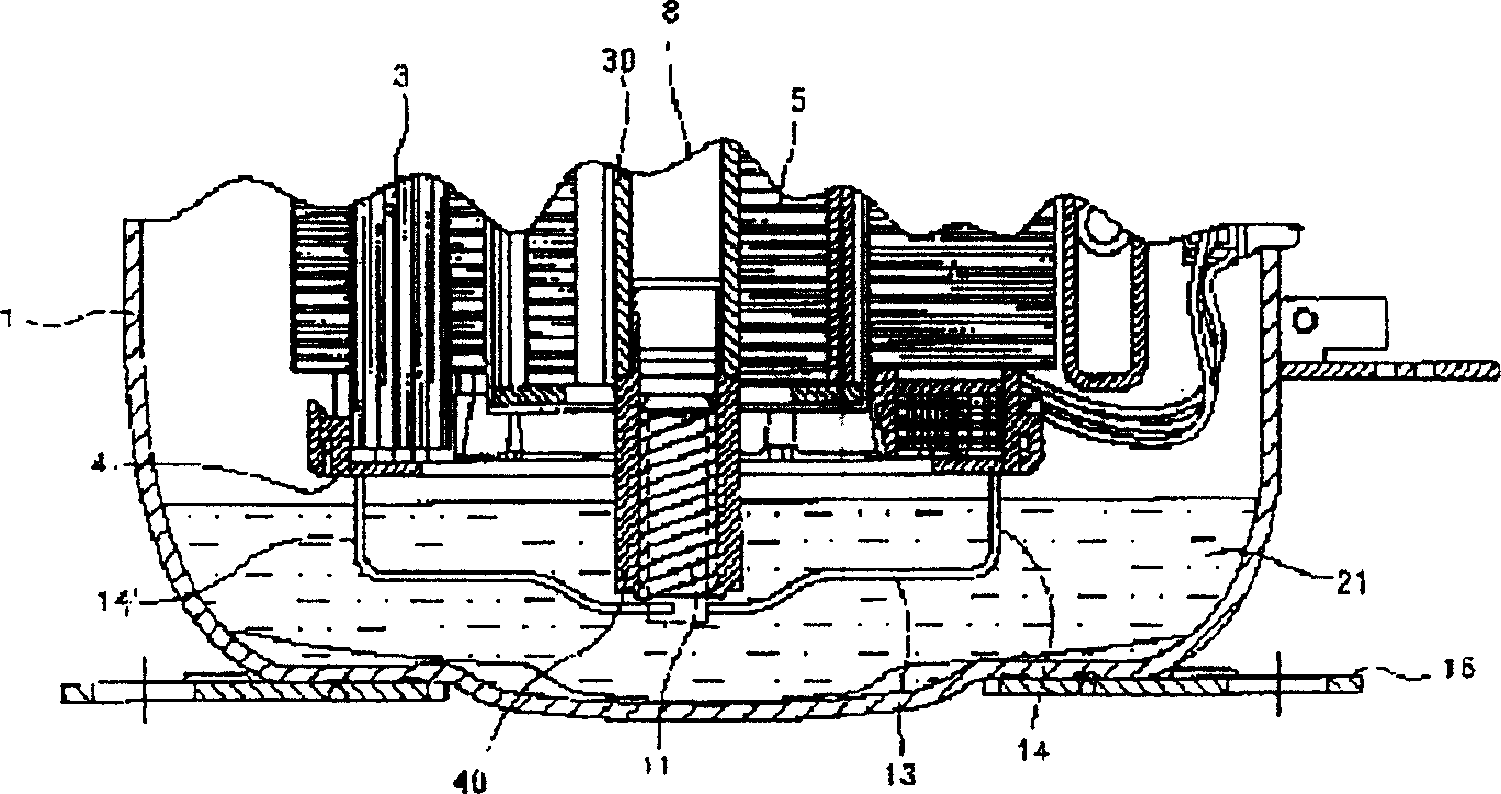

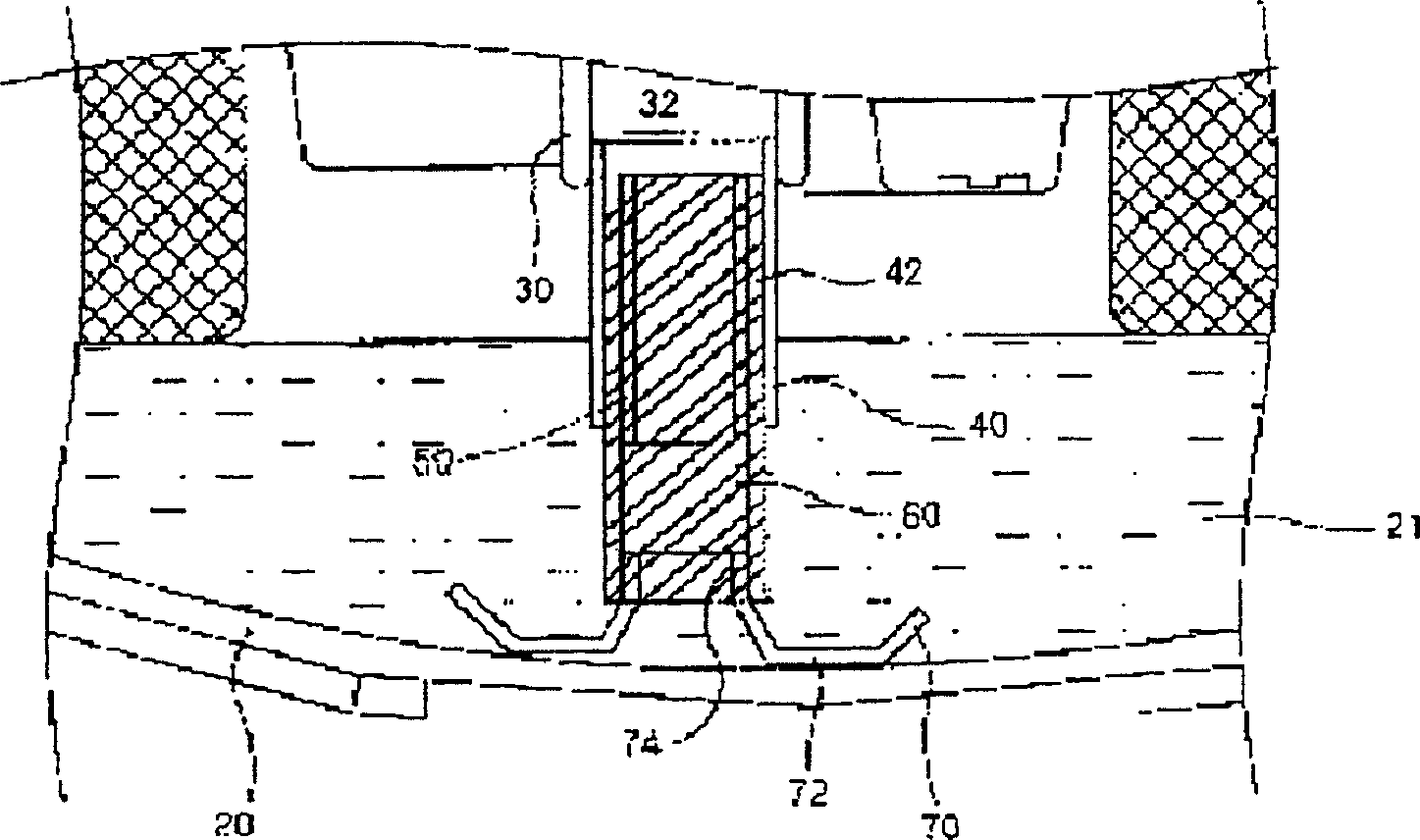

[0034] Such as figure 2 and image 3 As shown, the exterior of the compressor is an airtight container, and the airtight container 20 generally consists of an upper container and a lower container. The airtight container 20 is provided with a motor part that supplies power to the compressor and a compression part that compresses working fluid.

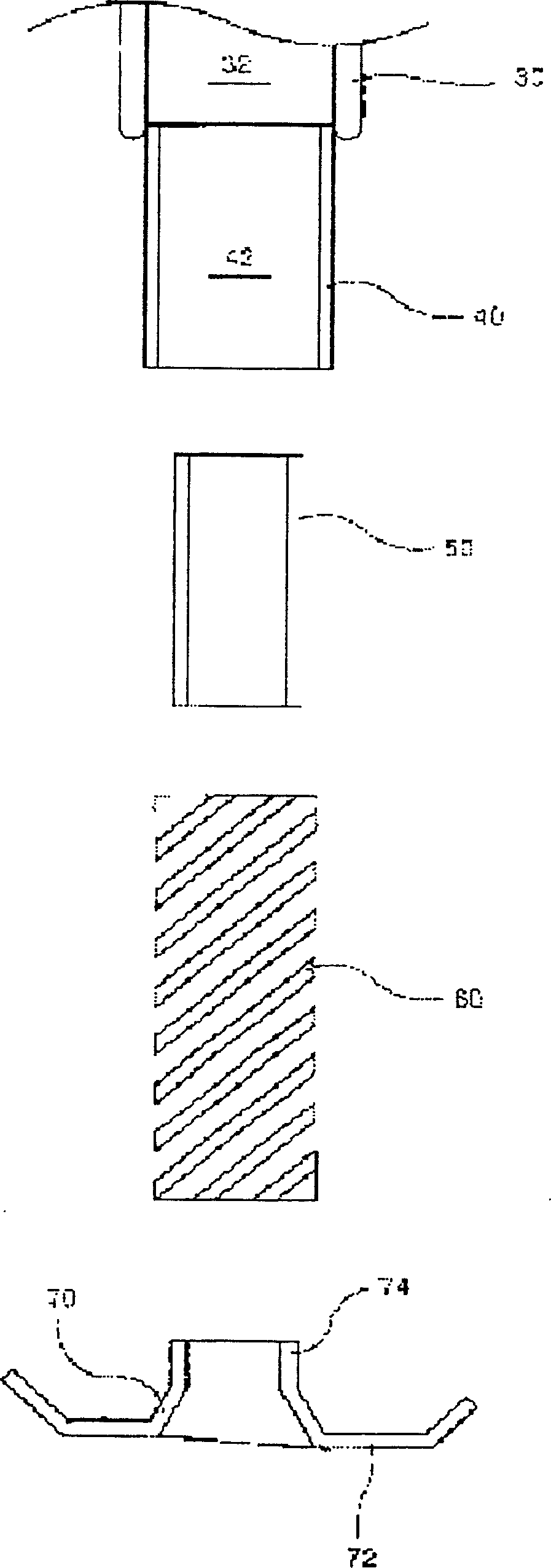

[0035] The motor part includes a stator and a rotor. The crankshaft 30 is arranged on the rotor and rotates integrally with the rotor to transmit power to the compression part. An oil passage 32 is formed inside the crankshaft 30 . The lubricating oil 8 in the lower part of the airtight container 20 is pumped to the upper part through the oil passage 32 to perform cooling and lubricating effects on the compression parts and the motor parts.

[0036] The oil supply member 40 is press-fitted and arran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com