Gas-solid cyclone fast separation device for lifting pipe

A swirl fast separation and riser technology, which is applied in chemical/physical processes, chemical instruments and methods, etc., can solve the problems of undiscovered literature and patent reports, and achieve the goals of avoiding overcracking reactions, efficient and rapid separation, and avoiding coking Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

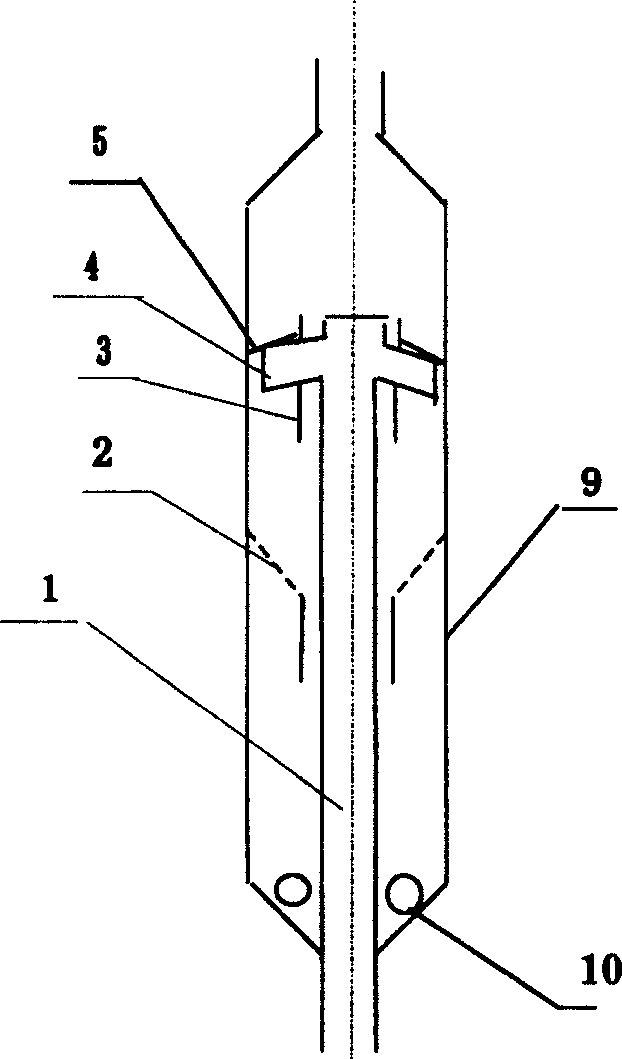

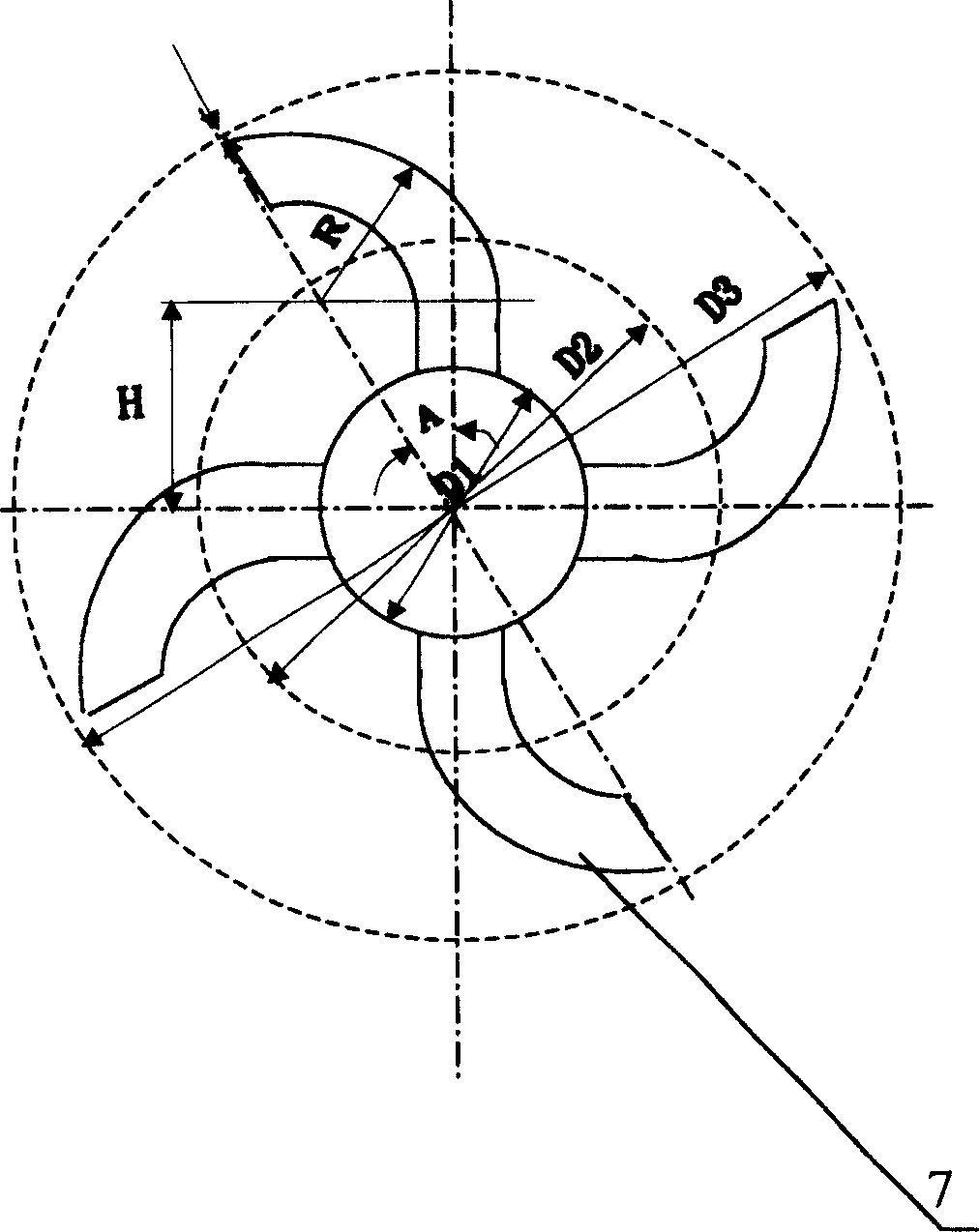

[0024] see figure 1 , in this embodiment, the riser (1) is placed inside the enclosure (9). The closing cover (9) is a cylindrical structure, and the inside of the closing cover (9) includes a riser (1), a conical stripping baffle (2), a splitter tube (3), a cyclone quick splitter (4), a splitter The baffle (5) and the stripper (10), the outlet end of the riser (1) is connected with the swirl quick splitter (4), and the splitter (3) is located at the outlet of the riser (1) and connected to the riser ( 1) Coaxial line, there is an annular channel between the outer wall of the outlet of the riser (1) and the inner wall of the splitter tube (3), and the multiple elbows (7) of the swirl quick splitter (4) respectively pass through the splitter tube (3) ), the outlet end of the elbow (7) is located in the space formed by the closure cover (9), the shunt cylinder (3) and the shunt baffle (5), and the shunt baffle (5) is placed in the swirl quick splitter ( 4) and welded on the inne...

Embodiment 2

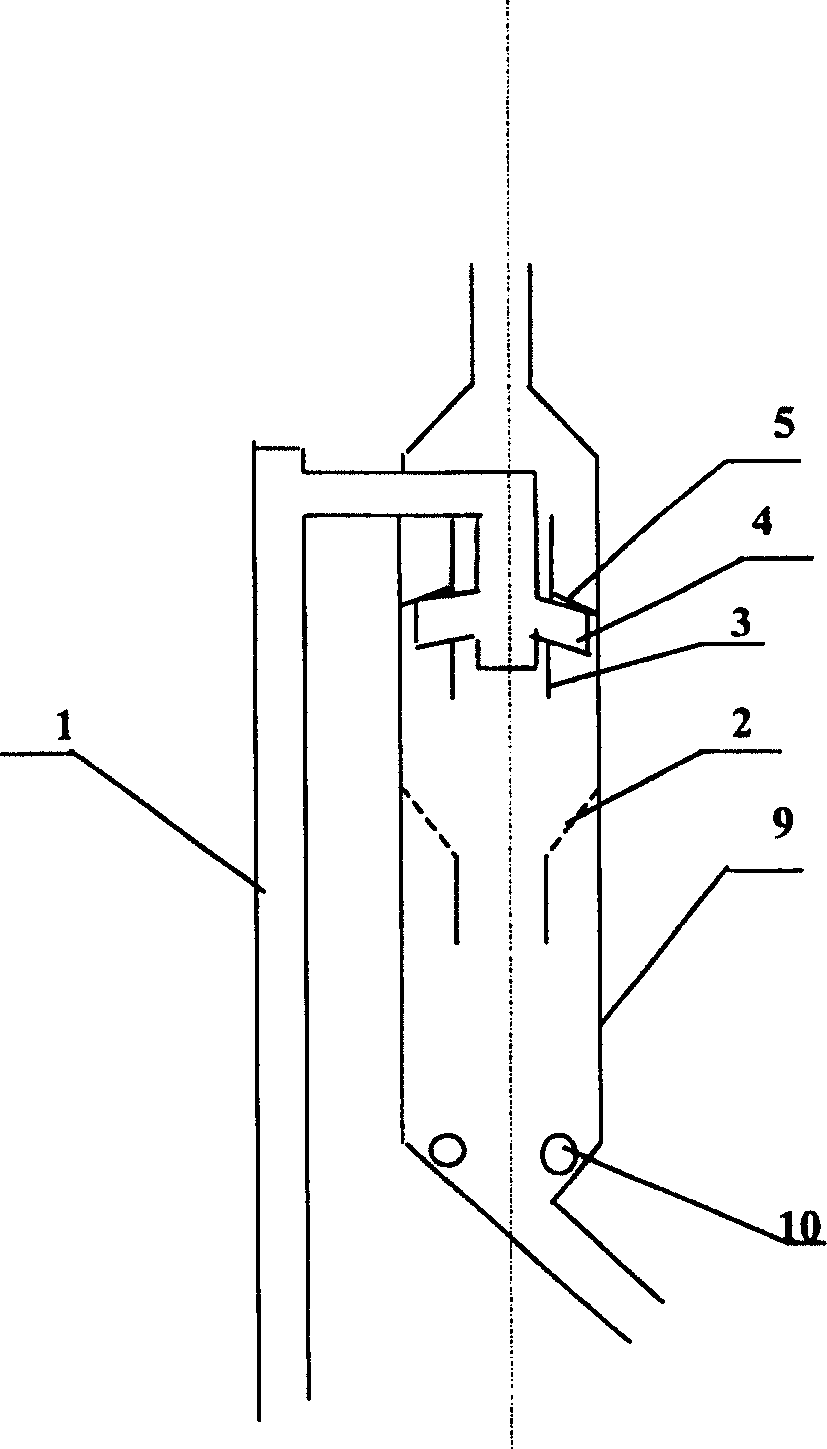

[0027] see figure 2 , in this embodiment, the riser (1) is placed outside the enclosure, and the upper part of the riser (1) turns above the diverter baffle (5), passes through the enclosure (9), and is placed downwards Inside the shunt cylinder (3). The closing cover (9) is a cylindrical structure, and the inside of the closing cover (9) includes a riser (1), a conical stripping baffle (2), a splitter tube (3), a cyclone quick splitter (4), a splitter The baffle (5) and the stripper (10), the outlet end of the riser (1) is connected with the swirl quick splitter (4), and the splitter (3) is located at the outlet of the riser (1) and connected to the riser ( The outlet of 1) is coaxial, and there is an annular channel between the outer wall of the outlet of the riser (1) and the inner wall of the splitter tube (3), and the multiple elbows (7) of the swirl quick splitter (4) respectively pass through the splitter The wall of the cylinder (3), the outlet end of the elbow (7) ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com