Light construction unit for on site pouring reinforced concrete filling

A reinforced concrete and cast-in-place technology, which is applied to building components, building structures, floor slabs, etc., can solve the problems of large hidden ribs, high material consumption, poor seismic performance, etc., and achieve improved strength and rigidity, and good integrity , the effect of high bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] The present invention will be further described below in conjunction with drawings and embodiments.

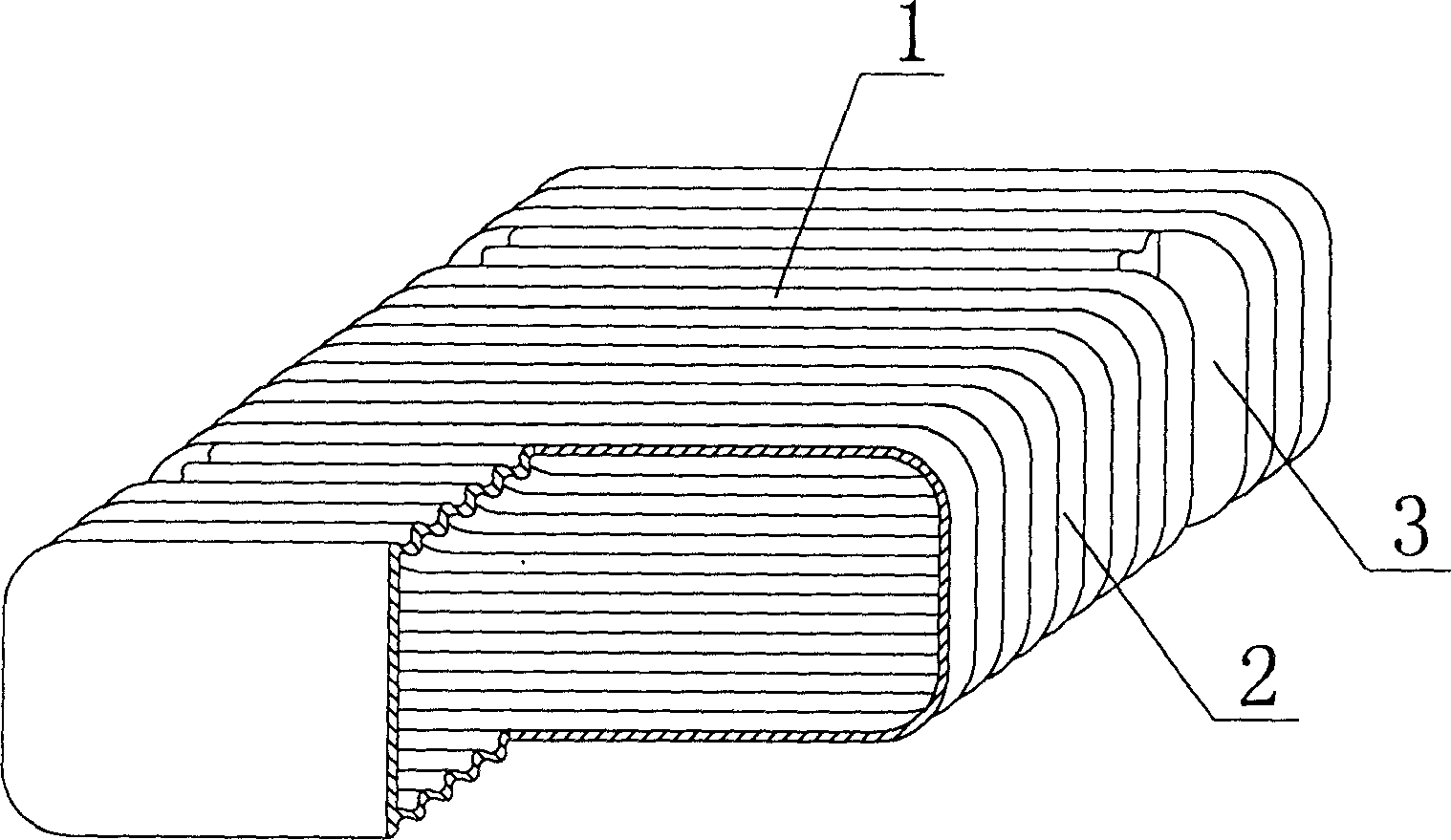

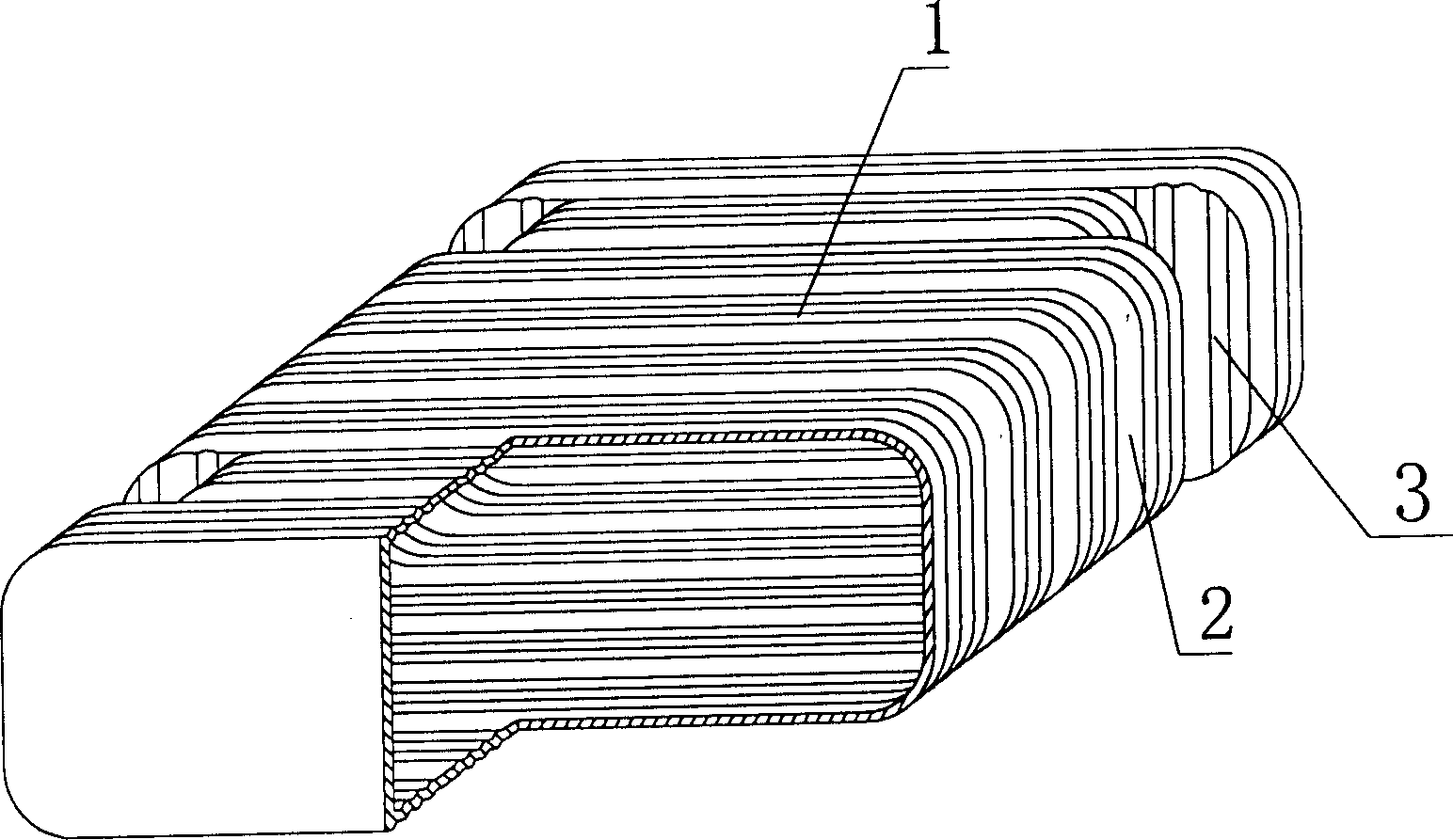

[0052] As shown in the drawings, the present invention includes a carcass 1, which is characterized in that the carcass 1 is a corrugated carcass, and at least one side 2 of the corrugated carcass 1 has at least one groove 3 running through the upper and lower surfaces. figure 1 It is a structural schematic diagram of Embodiment 1 of the present invention. figure 1 Among them, 1 is the corrugated carcass, 2 is the side of the corrugated carcass 1, and 3 is the groove. In the drawings, those with the same number have the same description. Such as figure 1 As shown, the carcass 1 is a corrugated carcass, and on the side 2 of the corrugated carcass 1 there are grooves 3 running through the upper and lower surfaces.

[0053] The present invention also lies in that the corrugations on the corrugated carcass 1 are positive corrugations, oblique corrugations, arc corrugation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com