Synchronous motor rotor

A technology for synchronous motors and rotors, applied to synchronous motors with stationary armatures and rotating magnets, magnetic circuit rotating parts, magnetic circuit shape/style/structure, etc., can solve the problems of weak anti-disturbance ability, asynchronous operation, easy Vibration and other problems occur, to achieve strong anti-disturbance ability, increased strength, and easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

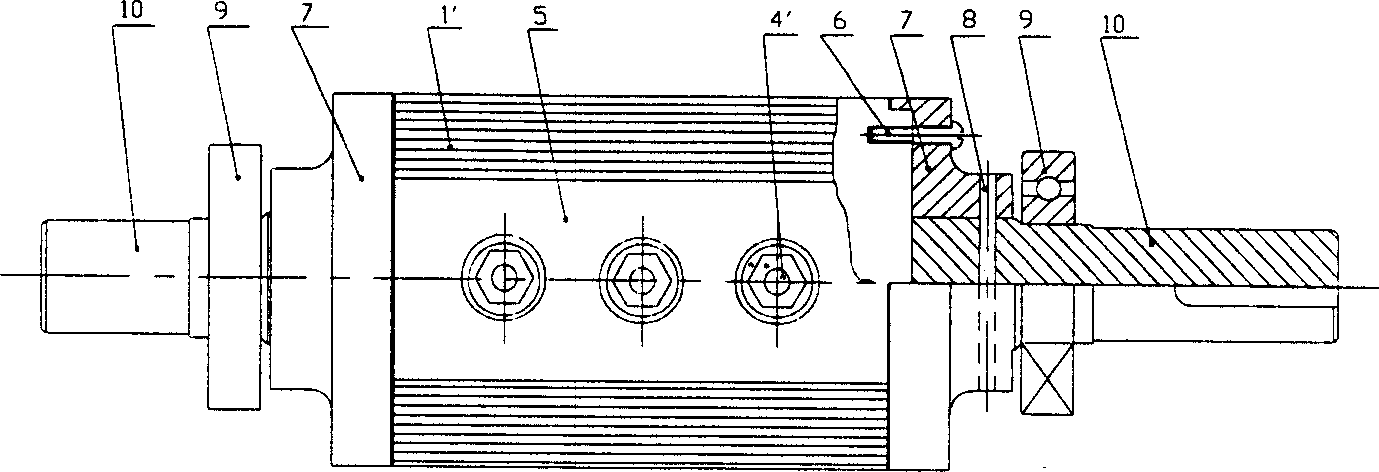

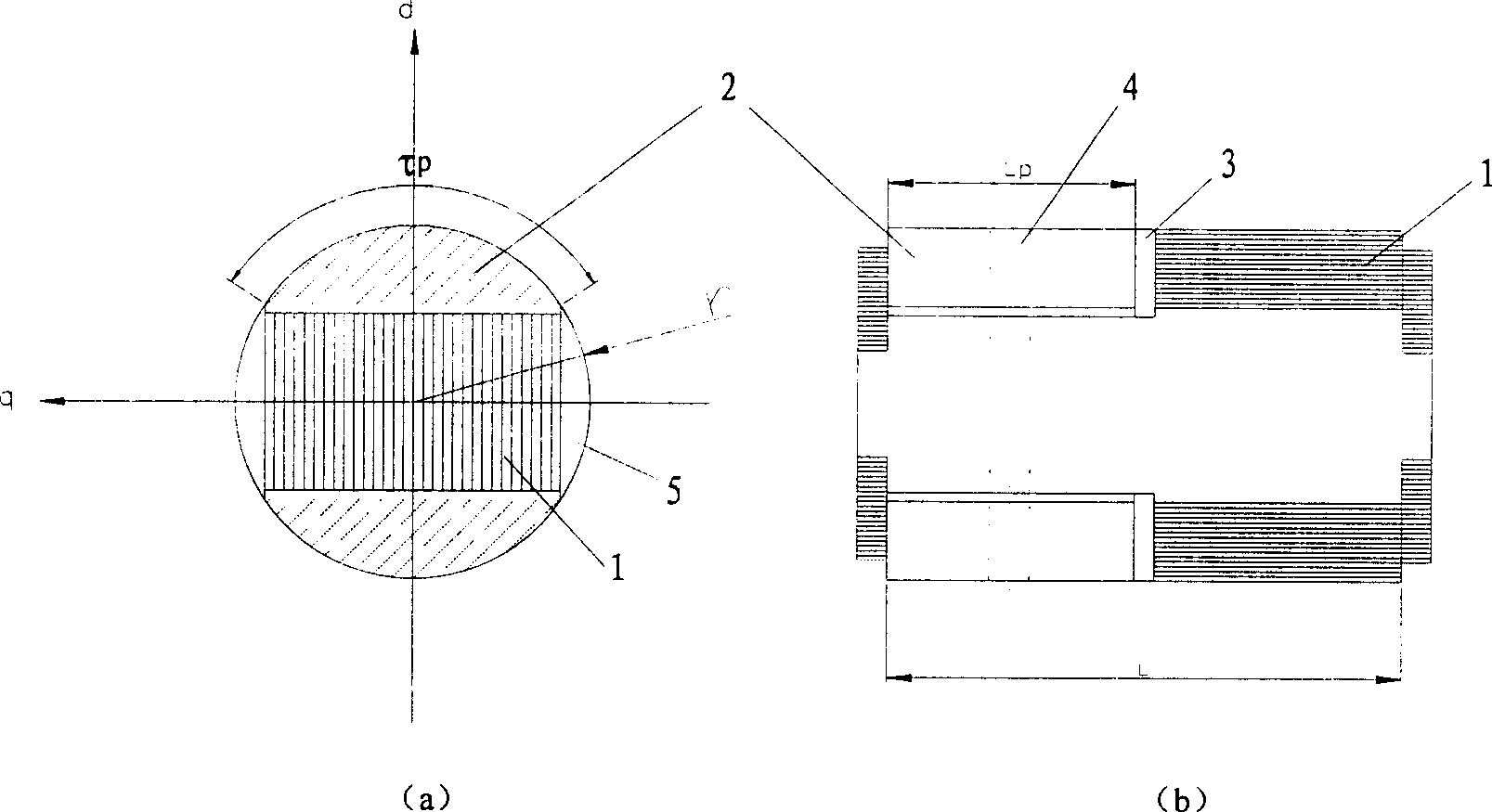

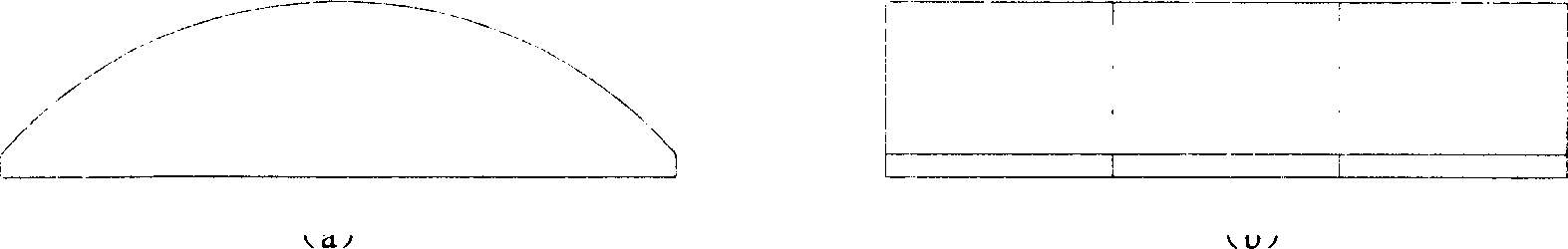

[0011] The structure of the existing ALA rotor is as follows figure 1 As shown, it includes ALA section 1' with rectangular longitudinal section, fixing bolt 4', splint 5, fixing screw 6, end cover 7, fixing pin 8, rotor bearing 9 and rotor shaft 10, ALA section 1 and splint 5 form a cylinder shape. The ALA section 1' is axially symmetrically cut off a certain length of laminations to form the ALA section 1, and then the crown permanent magnet 2 is fixed on the cut-off position so that it still forms a cylinder. According to the requirements on the performance of the motor, the length Lp of the crown permanent magnet 2 can be selected between 1 / 3 and 1 / 2 of the total length L of the ALA segment. When Lp is about L / 2, the overall performance of the motor is particularly good. The crown permanent magnet 2 can be bonded to the ALA segment 1 with a stron...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com