Support structure for safety helmet

A technology for safety helmets and shields, which is applied to headgear products, clothing, helmets, etc., can solve the problem that the wearer cannot provide safety guarantee, the wearer cannot provide a good wearing feeling, and the thickness of the cap body and the buffer pad changes. big problem

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

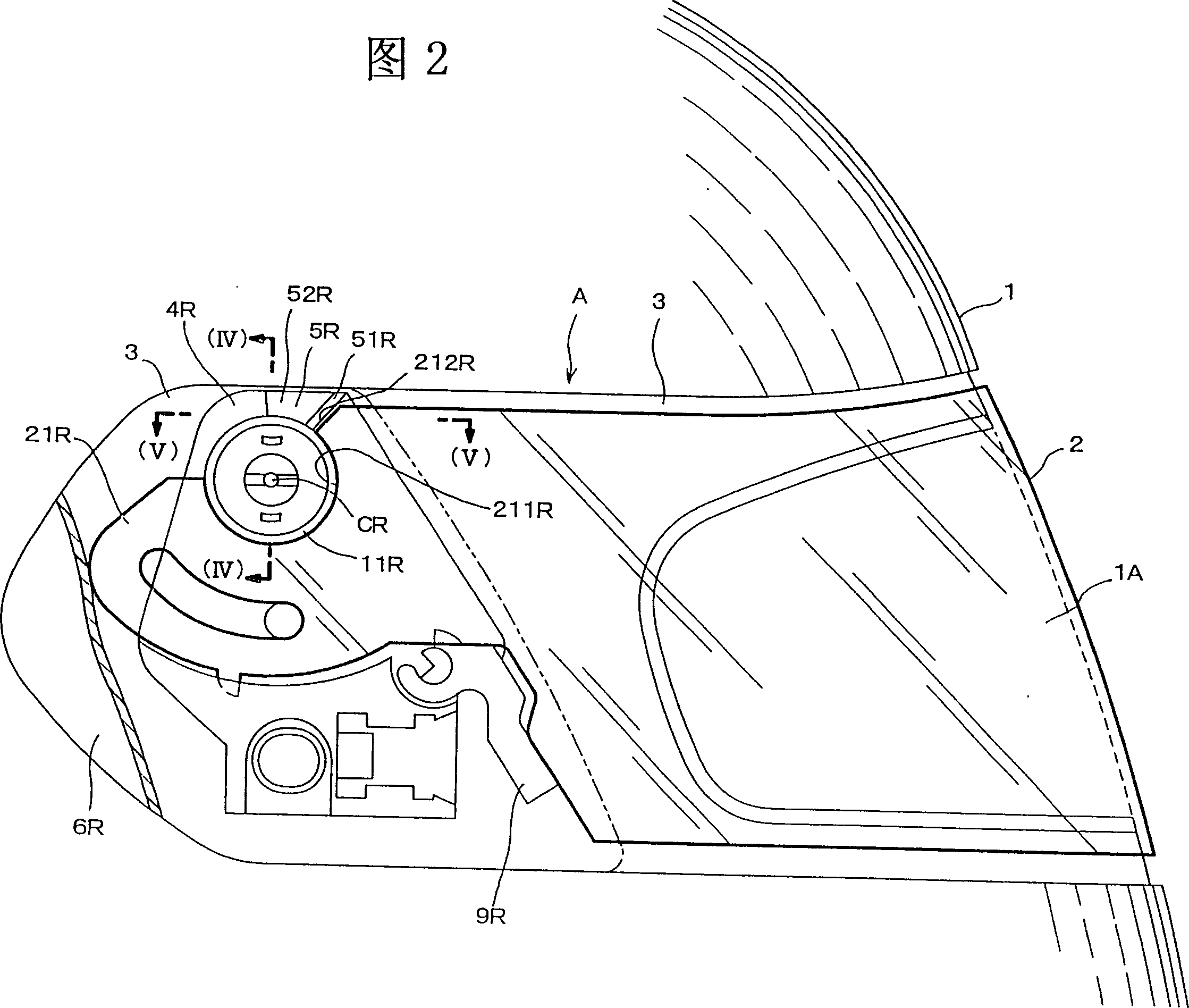

[0040] The technical means adopted by the shield support structure of the safety helmet of the present invention is to form a step portion 3 at least to accommodate the shield 2 on the shield installation position of the cap body 1. When the shield is fully closed, its appearance forms a shield. The outer surface of the cover 2 is substantially on the same plane as the outer surface of the cap body 1, and the shield mounting parts 21L, 21R of the supporting shafts 11L, 11R on the left and right sides of the cap body 1 can be arranged on the base element of the cap body 1. The pivot centers CL and CR on 4L and 4R are rotated around the center to open and close the shield 2. It is characterized in that when the shield 2 is fully closed, the axis C1L of one side support shaft (11L in the figure) It is the state behind the above-mentioned rotation axis center CL. When the shield 2 is moved forward in this state, and the axis C1L of the support shaft 11L advances to a position conce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com