Device and method for removing thin layers on support material

A substrate and equipment technology, applied in the field of surface layer ablation process of thin film solar cells, can solve the problems of component contamination, damage to the substrate surface, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

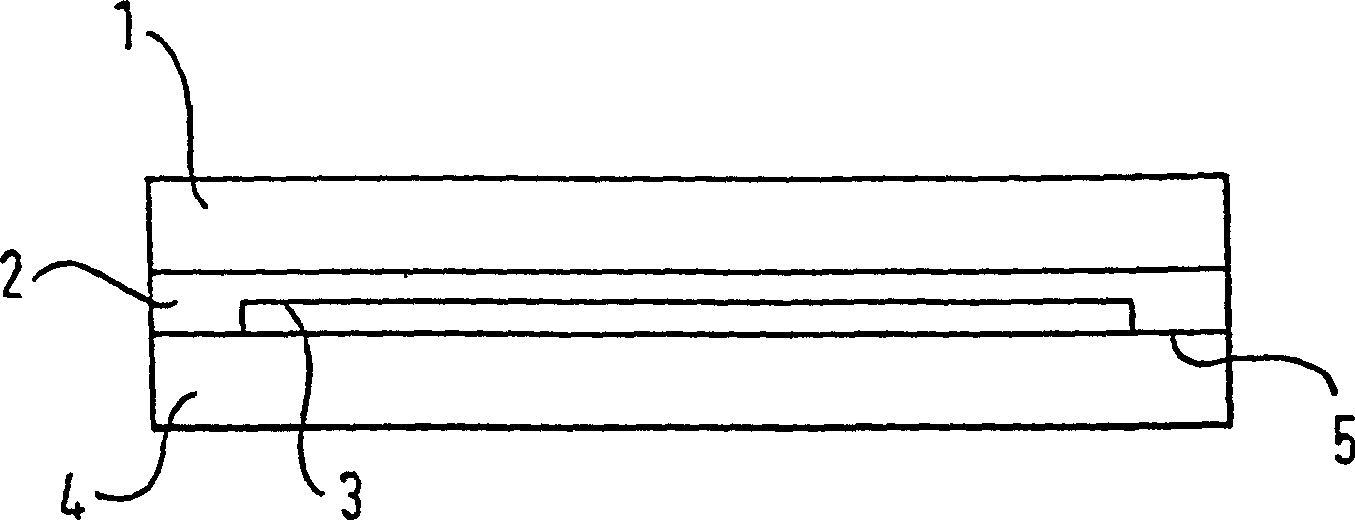

[0045] refer here figure 1 , illustrating a cross-section through an encapsulated thin-film solar cell. A solar cell actually comprises a substrate 4, a film layer 3 deposited and patterned thereon, a laminate layer 2 and a glazing layer applied thereon. The thickness of the carrier film layer 3 is in the range of 0.1 μm to 5 μm, and the substrate 4 is preferably made of float glass. In order to eliminate the current path to the current-carrying film layer 3 and to prevent moisture damage to the film itself, the surface region 5 of the substrate 4 does not contain a current-carrying layer. This is why the surface region 5 according to the invention is delaminated.

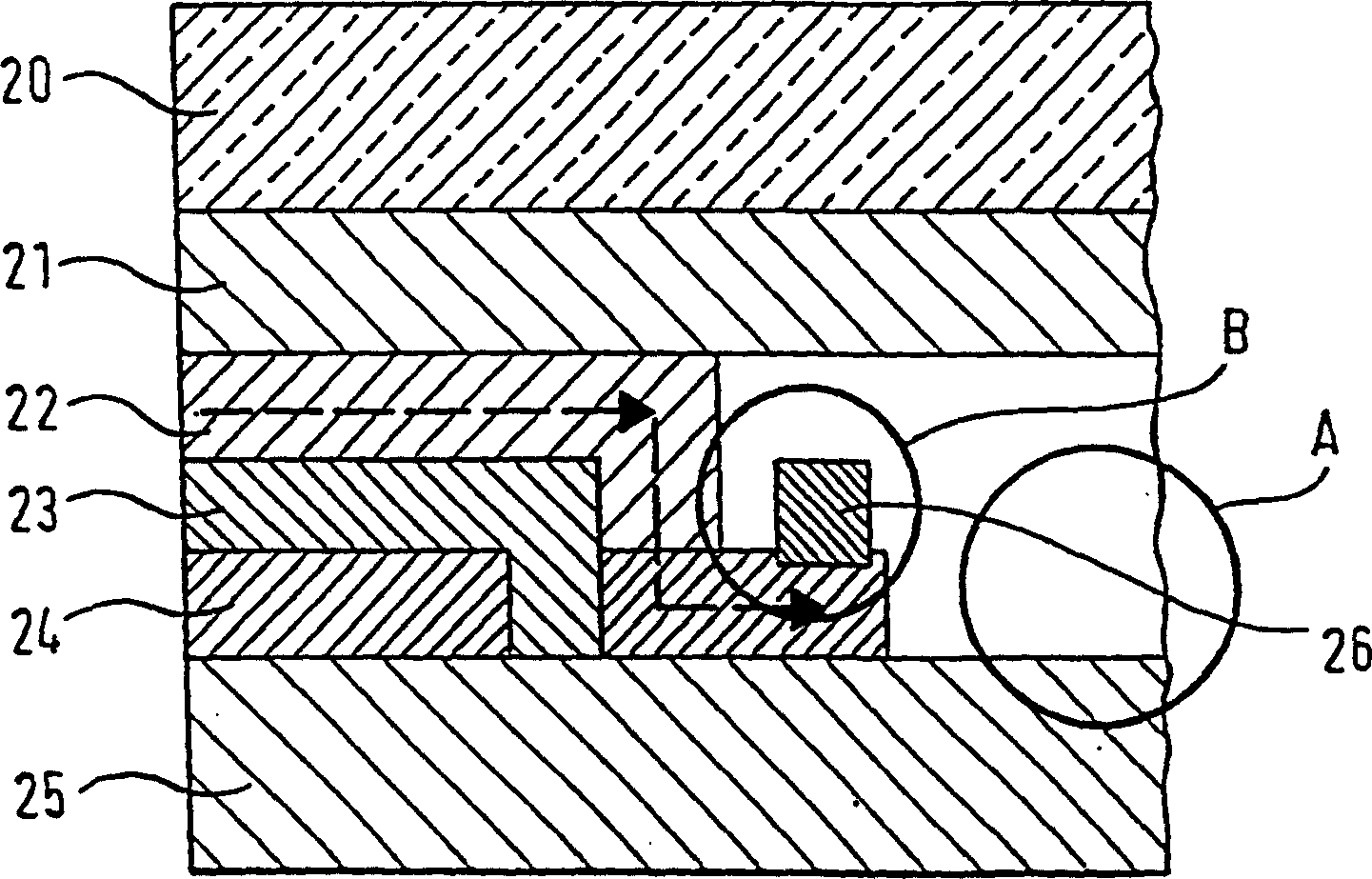

[0046] refer here figure 2 , illustrating a cross-section through an encapsulated thin-film solar cell showing the thin-film layer sequence and the contacting rear electrode. In substrate thin-film solar cells, the thin-film layer sequence consists of rear electrode 24 , absorber layer 23 and front electrode 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com