Method for producing an electromagnetic valve

A technology for solenoid valves and valve housings, applied in the direction of valve operation/release devices, valve details, multi-way valves, etc., to achieve uniform solder distribution, uniform high-quality brazing connections, and improved mechanical stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

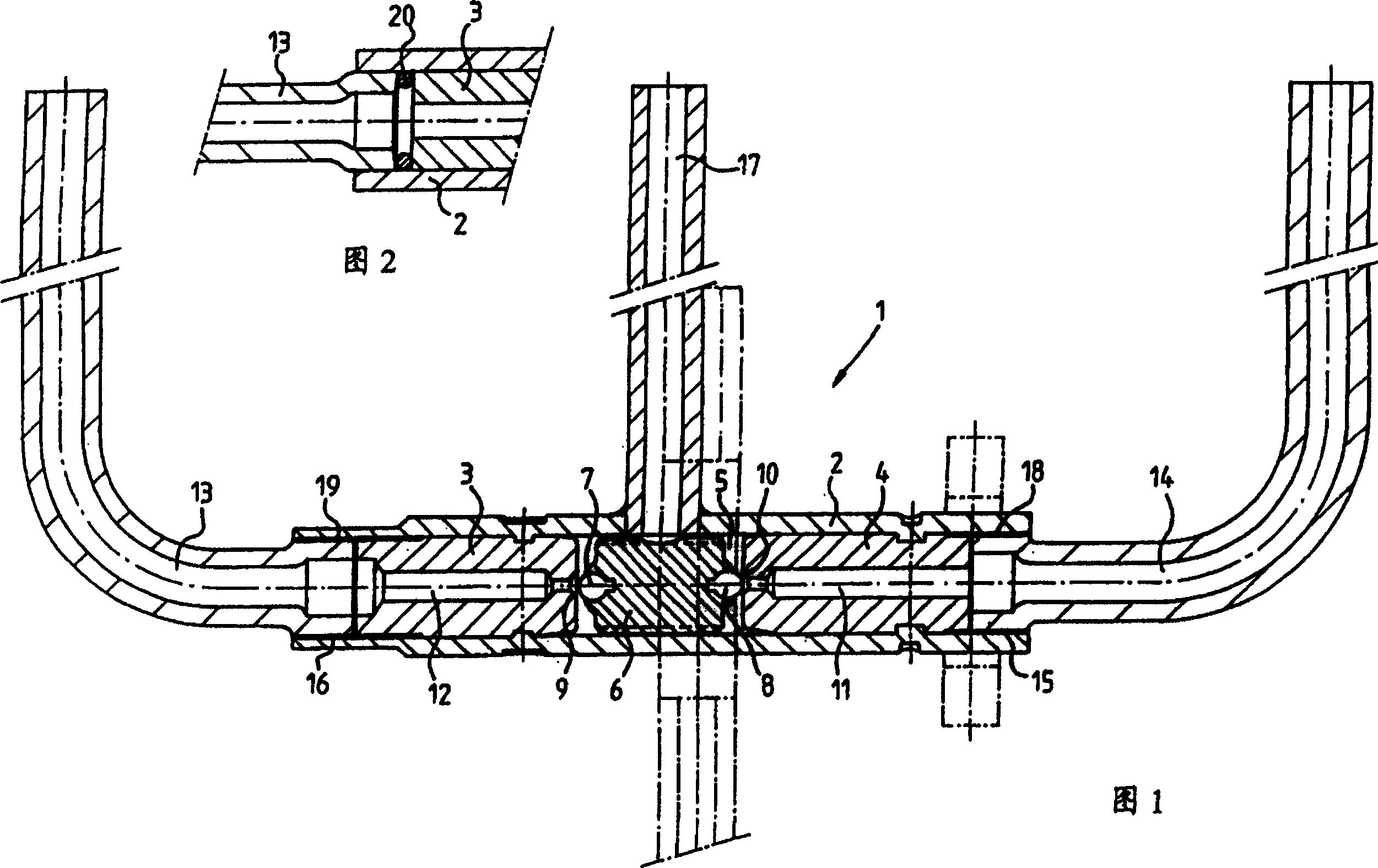

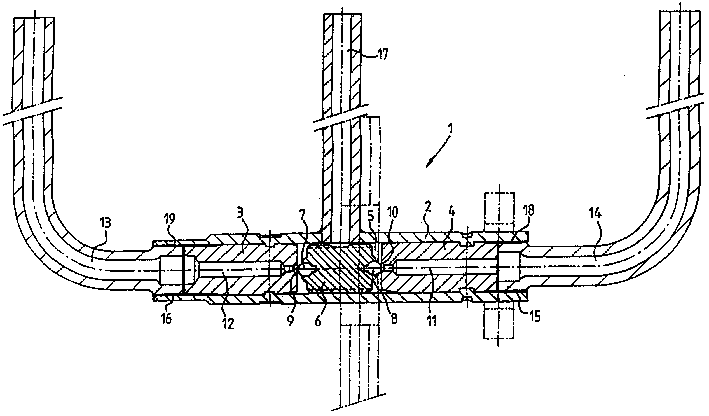

[0025] The valve 1 comprises a tubular valve housing 2 in which a valve chamber 5 is delimited by pole pieces 3 and 4 . A valve body 6 is movably mounted in the valve chamber 5 and can press two spherical seals 7 and 8 onto valve seats 9 and 10 fitted in the pole pieces 3 and 4 respectively.

[0026] The pole shoes 3 and 4 have connecting channels 11 and 12 which are connected to two connecting pipes 13 and 14 which are pushed into corresponding holes 15 and 16 in the valve housing 2 until they abut against the pole shoes 3 and 4 .

[0027] The valve 1 is used to switch the connection between the two connecting pipes 13 and 14 of a line 17 leading transversely into the valve chamber. In this way, the valve is bistable in any end position of the valve body 6 by means of a permanent magnet, not shown in detail, and can be actuated by a solenoid coil (also not shown in detail).

[0028] FIG. 1 shows the state after the brazed connection has been completed, wherein connecting pip...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap