Coloured electroluminescent wire, production method and production equipment thereof

An electroluminescent wire and a colorful technology, applied in the field of electroluminescent light sources, can solve the problems of easy loss of function, inability to emit light uniformly, complicated processes, etc., and achieve the effect of increasing the structure density and improving the luminous efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

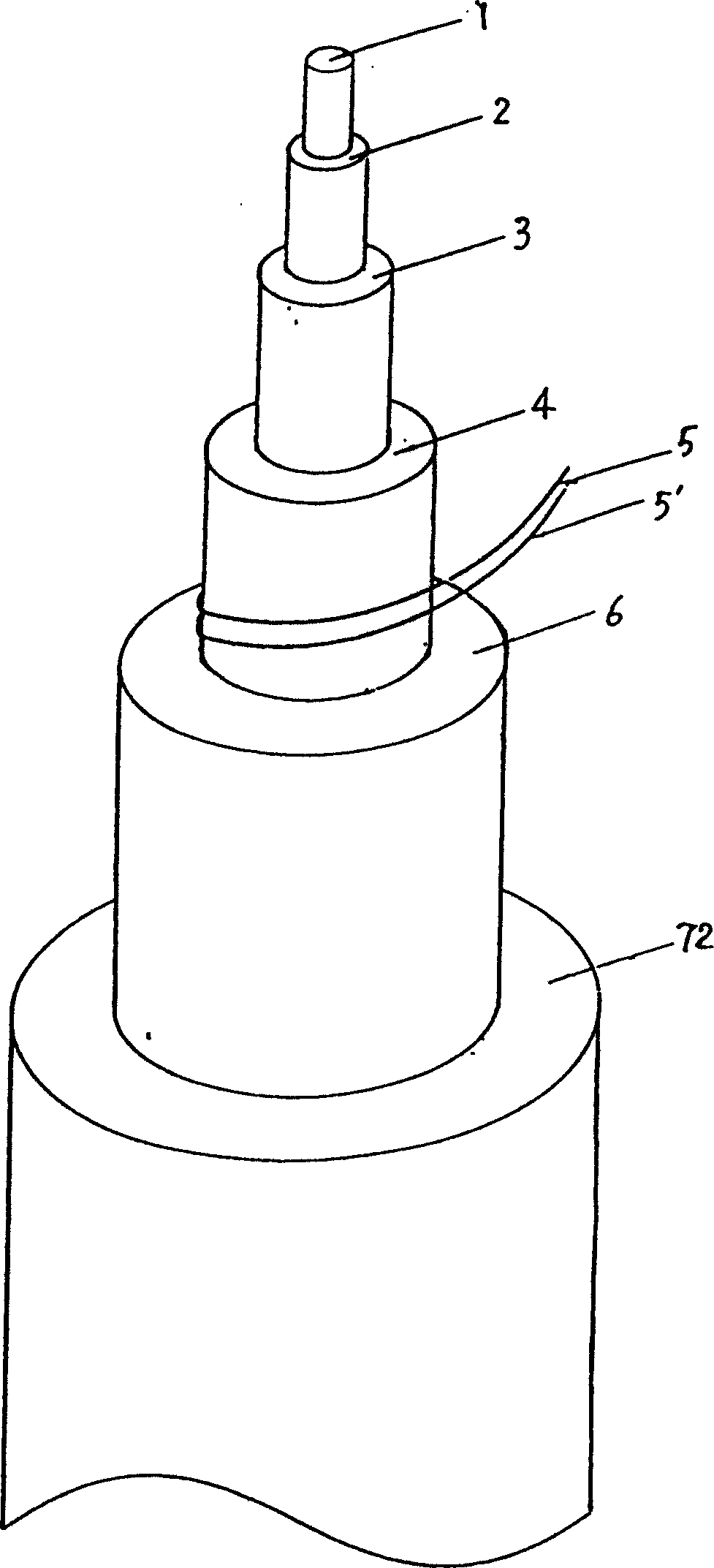

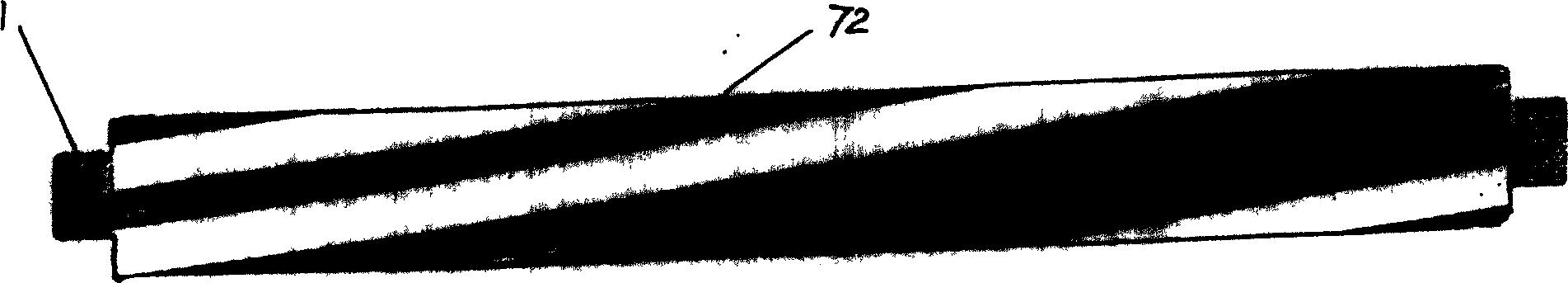

[0040] Such as figure 1 , figure 2 As shown, a colorful spiral electroluminescent wire, it includes:

[0041] A), a metal wire is used as the center pole core wire 1;

[0042] B), the intermediate insulating layer 2 provided on the core wire 1;

[0043] C), the light-emitting layer 3 arranged on the intermediary insulating layer 2;

[0044] D), the conductive layer 4 provided on the light-emitting layer 3;

[0045] E), at least one transmission wire 5, 5' is arranged at intervals on the conductive layer 4;

[0046] F), a transparent polymer sleeve 6 or a colored polymer sleeve 71 is coated on the outside of the surface of the conductive layer 4 that has been wound with the transmission wires 5, 5';

[0047] G), the outer layer of the transparent polymer sleeve 6 or colored polymer sleeve 71 is coated with a colorful spiral polymer sleeve 72 composed of at least 1 to 8 different colors, which is arranged on the luminous line The outermost layer not only plays the role of...

Embodiment 2

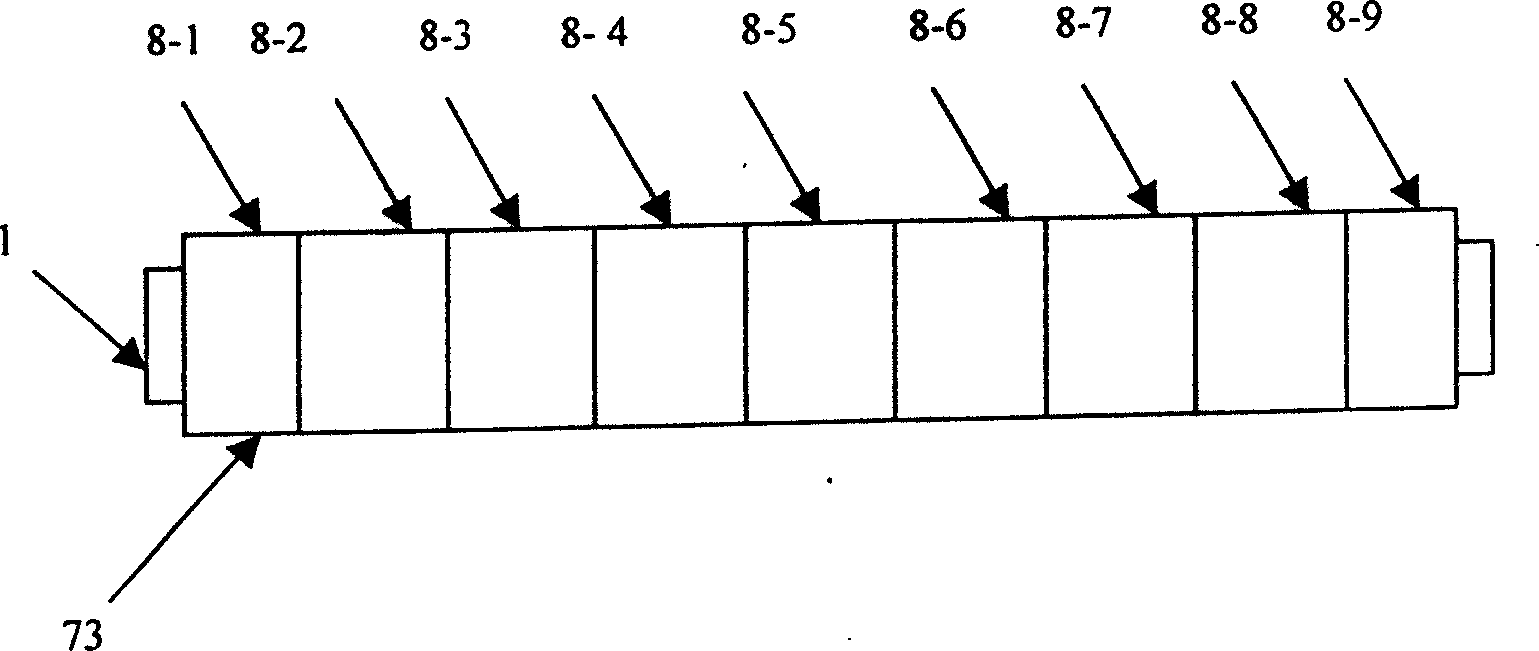

[0079] Such as figure 1 , image 3 As shown, a colorful segmented electroluminescent line, which includes:

[0080] A), a metal wire is used as the center pole core wire 1;

[0081] B), the intermediate insulating layer 2 provided on the core wire 1;

[0082] C), the light-emitting layer 3 arranged on the intermediary insulating layer 2;

[0083] D), the conductive layer 4 provided on the light-emitting layer 3;

[0084] E), at least one transmission wire 5, 5' is arranged at intervals on the conductive layer 4;

[0085] F), a transparent polymer sleeve 6 or a colored polymer sleeve 71 is coated on the outside of the surface of the conductive layer 4 of the wound transmission wire 5, 5′;

[0086] G. The outer layer of the transparent polymer sleeve 6 or the colored polymer sleeve 71 is coated with a polymer sleeve 73 composed of at least 1 to 8 different colors, which is arranged at the end of the luminous line. The outer layer plays the role of covering and protecting t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com