Process for preparing titanium carbonitride ceramic powder body by utilizing plasma chemical gas phase synthesis method

A titanium carbonitride ceramic and plasma technology is applied in the field of preparing nano-scale and submicron-scale titanium carbonitride ceramic powders, and can solve the problems of complicated process, large original crystal size of titanium carbonitride powder and fine grinding process. Easy doping and other problems, to achieve the effect of continuous and stable production, uniform particle size distribution, and ultra-fine particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

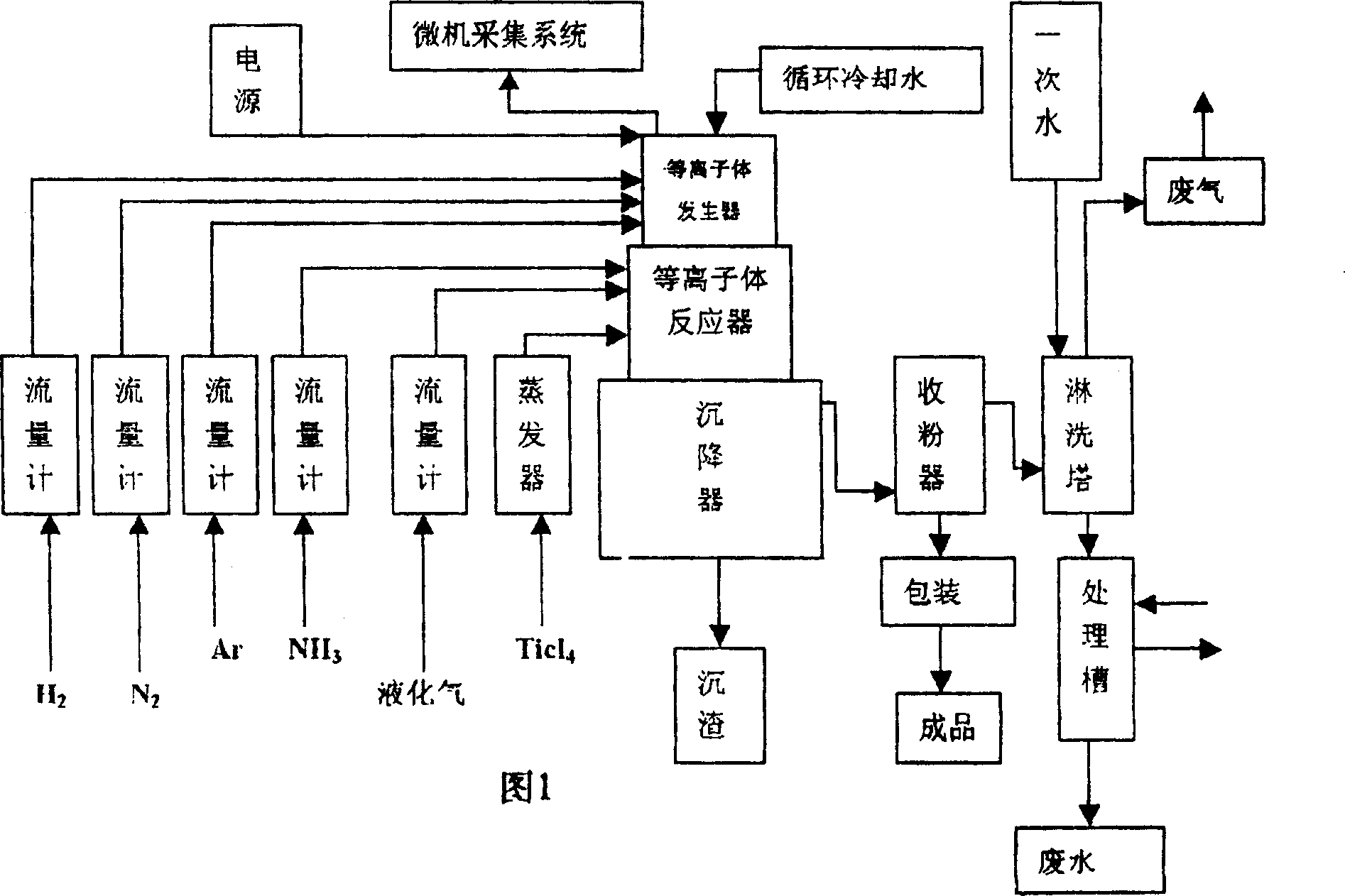

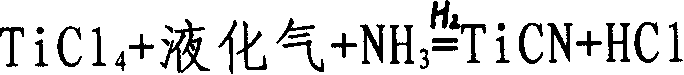

[0022] Example 1: A process for preparing titanium carbonitride ceramic powder by a plasma chemical vapor phase synthesis method. First, the plasma working gas N is introduced into the plasma generator. 2 -H 2 -Ar, press N 2 9m 3 / h; H 2 27m 3 The flow rate of / h is continuously injected, and 30 liters / min of Ar is injected, the plasma power supply is started, and a plasma arc is generated in the plasma generator, and the Ar gas is turned off after the arc starts normally. The gas after the arc is heated to a high temperature of 4800°C and then enters the reactor, and then the TiCl evaporated by the evaporator is respectively 4 And the liquefied gas and NH delivered by the flowmeter 3 Send it into the reactor to decompose quickly, use liquefied gas as carbon source, keep liquefied gas, NH 3 and TiCl 4 The liquid weight ratio is continuously injected at a ratio of 1:1:7, and the reaction temperature in the plasma reactor is maintained at 1200°C. Decomposition occurs rap...

Embodiment 2

[0034] Embodiment 2: A kind of process of preparing titanium carbonitride ceramic powder by plasma chemical vapor synthesis method, at first pass into plasma working gas N in the plasma generator 2 -H 2 -Ar, press N 2 11m 3 / h; H 2 30m 3 The flow rate of / h is continuously injected, and 30 liters / min of Ar is injected, the plasma power supply is started, and a plasma arc is generated in the plasma generator, and the Ar gas is turned off after the arc starts normally. The gas after the arc is heated to a high temperature of 5000°C and enters the reactor, and then the TiCl evaporated by the evaporator is separately 4 And the liquefied gas and NH delivered by the flowmeter 3 Send it into the reactor to decompose quickly, use liquefied gas as carbon source, keep liquefied gas, NH 3 and TiCl 4 The liquid weight ratio is continuously injected at a ratio of 1:1:9, and the reaction temperature in the plasma reactor is maintained at 1250°C. Decomposition occurs rapidly in the p...

Embodiment 3

[0046] Embodiment 3: A kind of process of preparing titanium carbonitride ceramic powder by plasma chemical vapor synthesis method, at first pass into plasma working gas N in the plasma generator 2 -H 2 -Ar, press N 2 13m 3 / h; H 2 32m 3 The flow rate of / h is continuously injected, and 30 liters / min of Ar is injected, the plasma power supply is started, and a plasma arc is generated in the plasma generator, and the Ar gas is turned off after the arc starts normally. The gas after the arc is heated to a high temperature of 5200°C and then enters the reactor, and then the TiCl evaporated by the evaporator is respectively 4 And the liquefied gas and NH delivered by the flowmeter3 Send it into the reactor to decompose quickly, use liquefied gas as carbon source, keep liquefied gas, NH 3 and TiCl 4 The liquid weight ratio is continuously injected at a ratio of 1:1:11, and the reaction temperature in the plasma reactor is maintained at 1300°C. Decomposition occurs rapidly in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com