Device for measuring at least one parameter of a medium flowing in a pipe

A pipeline and medium technology, applied in the field of devices for measuring at least one parameter of the medium flowing in the pipeline, to achieve the effects of reducing pollution, reducing the formation of dead water areas and eddy areas, and improving measurement results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

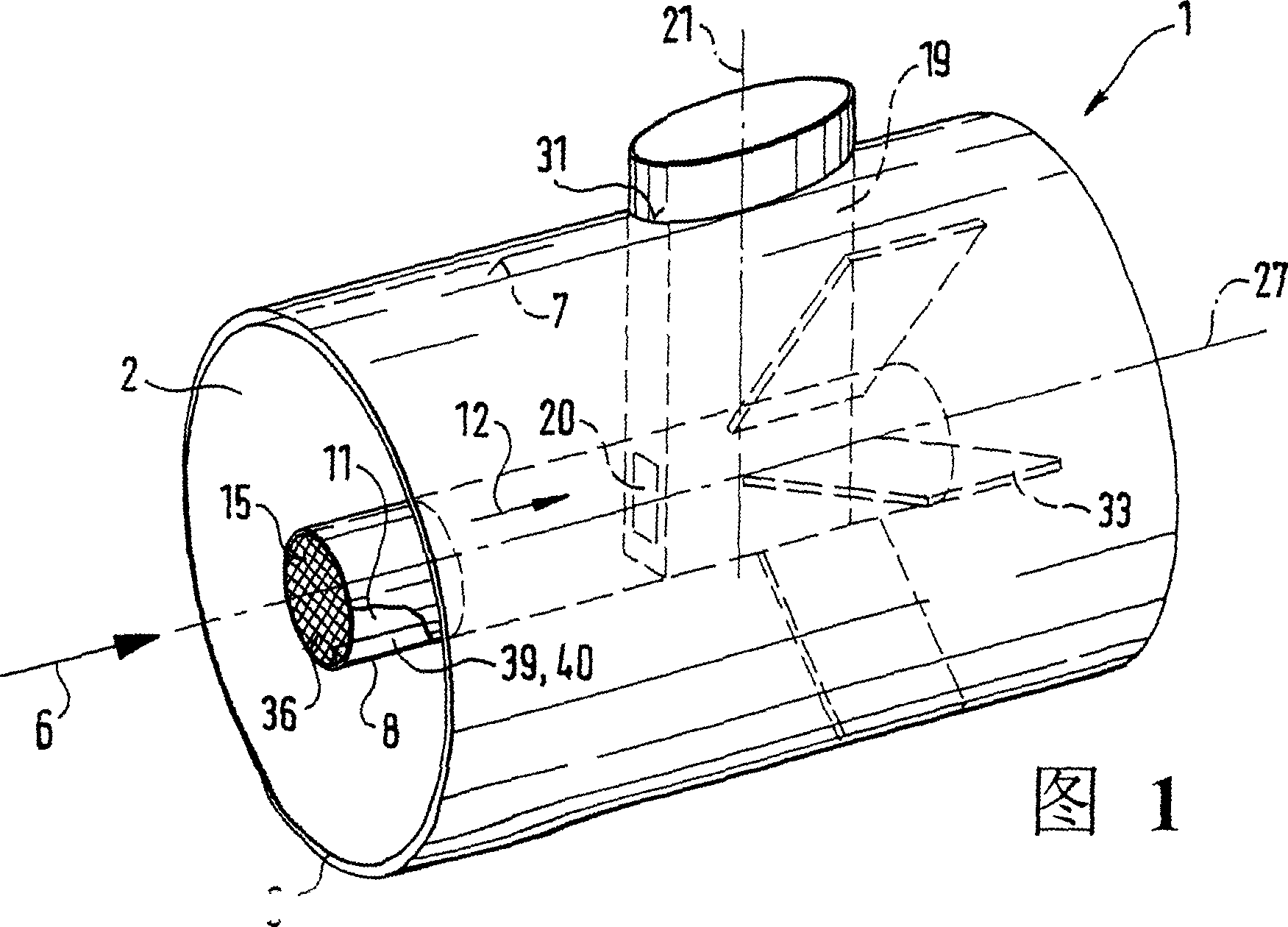

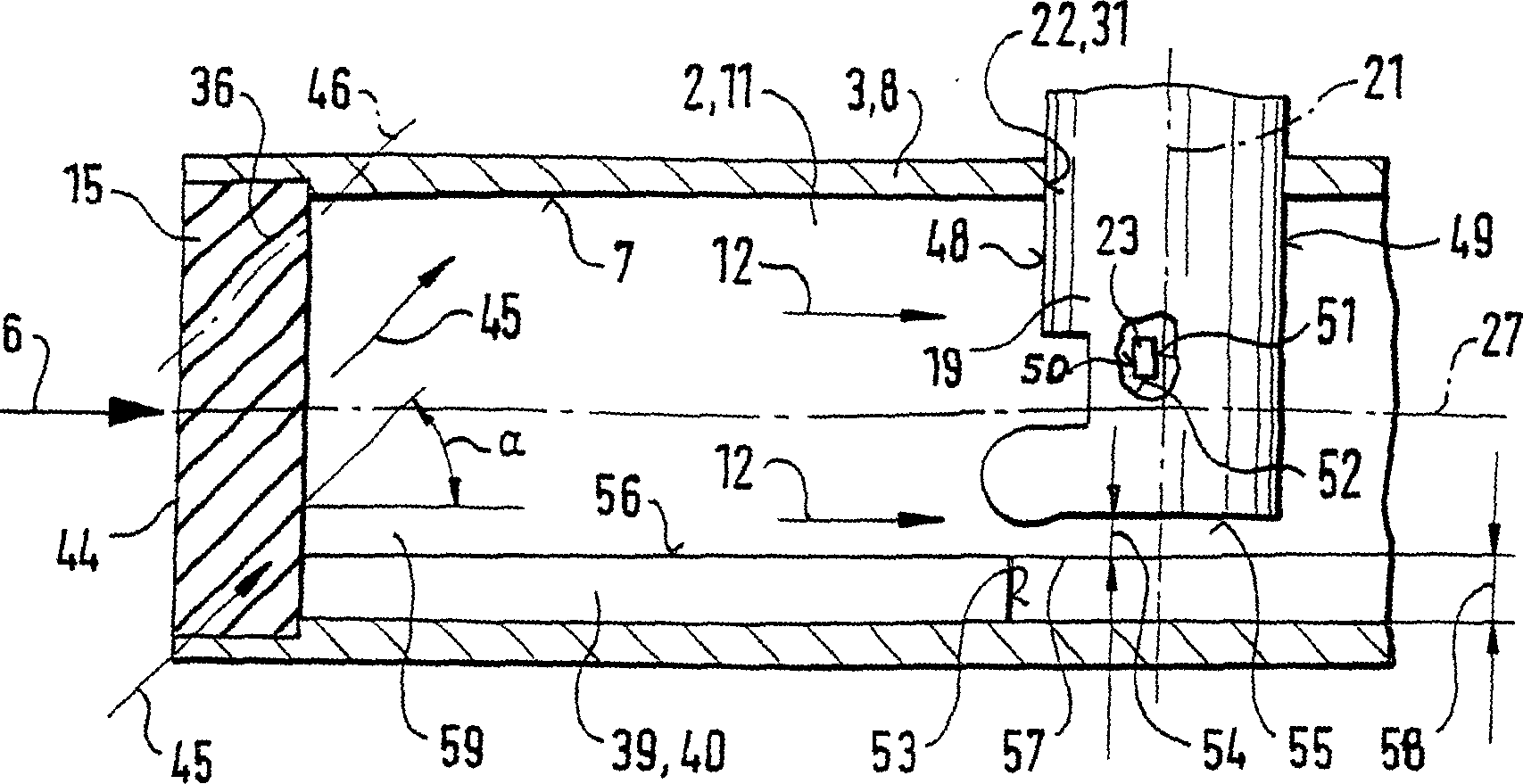

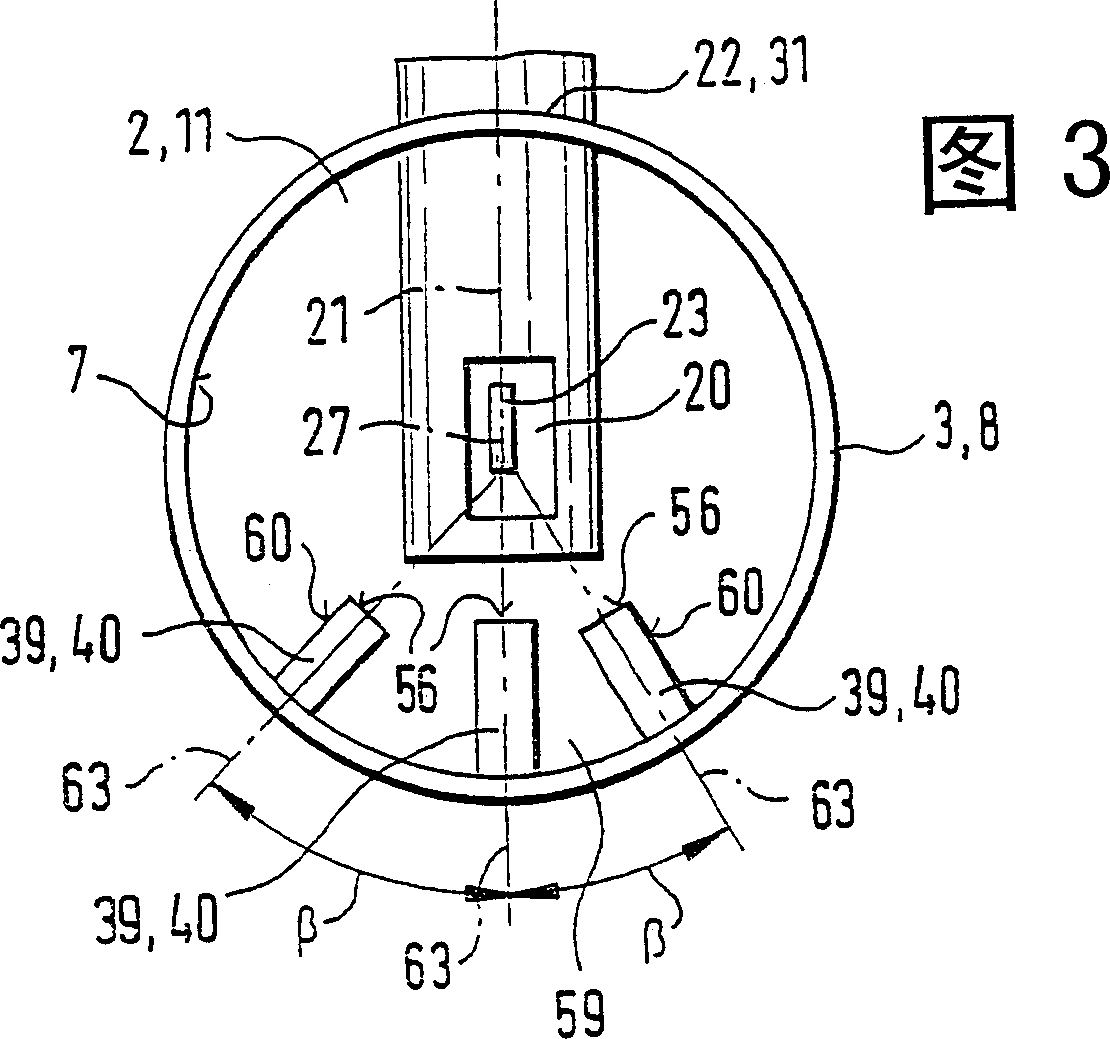

[0039] FIG. 1 shows a device 1 for measuring at least one parameter, in particular a parameter of the air mass flow, of a medium flowing in a line 2 , in particular of the intake air mass of an internal combustion engine. Parameters of a flowing medium include, for example, air mass flow, temperature, pressure or volume flow velocity for ascertaining the air mass, which are determined by suitable sensors. Other parameters can also be measured using the device 1 . The pipe 2 has a pipe wall 3 . In the line 2 the medium flows along the main flow direction 6 indicated by the arrow. The pipe 2 has an inner wall 7 . In the pipe 2 there is, for example, a pipe body 8 distributed radially at a certain distance from the pipe 2 and through which the medium flows. The tubular body 8 has a throughflow channel 11 and a protective grid 15 is arranged in its end region upstream in the direction of fluid flow. The protective grid 15 can be a wire braid, or a plate-shaped grid. It can al...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com