Electro-hydraulic proportional servo valve shaft control method considering time-varying parameter uncertainty

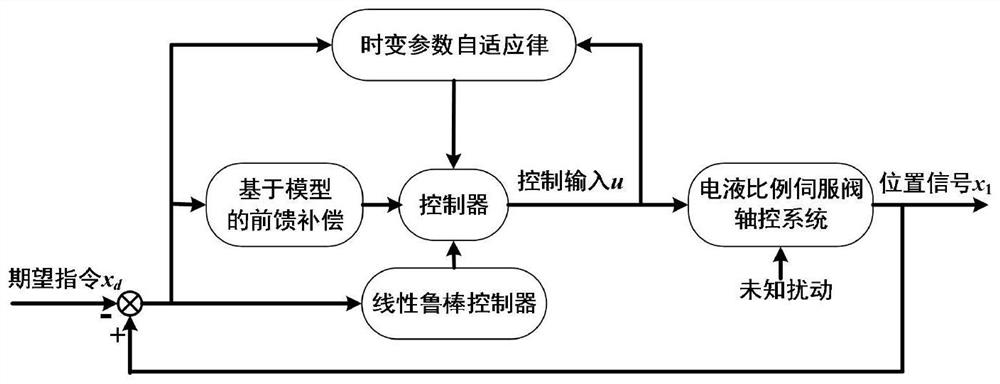

An electro-hydraulic proportional, time-varying parameter technology, applied in the direction of adaptive control, general control system, control/regulation system, etc., can solve the problems of inability to obtain high-precision control performance, deterioration of system tracking performance, deterioration of control performance, etc. Achieve the effect of avoiding the differential explosion problem, high-precision tracking performance, and strong anti-interference ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

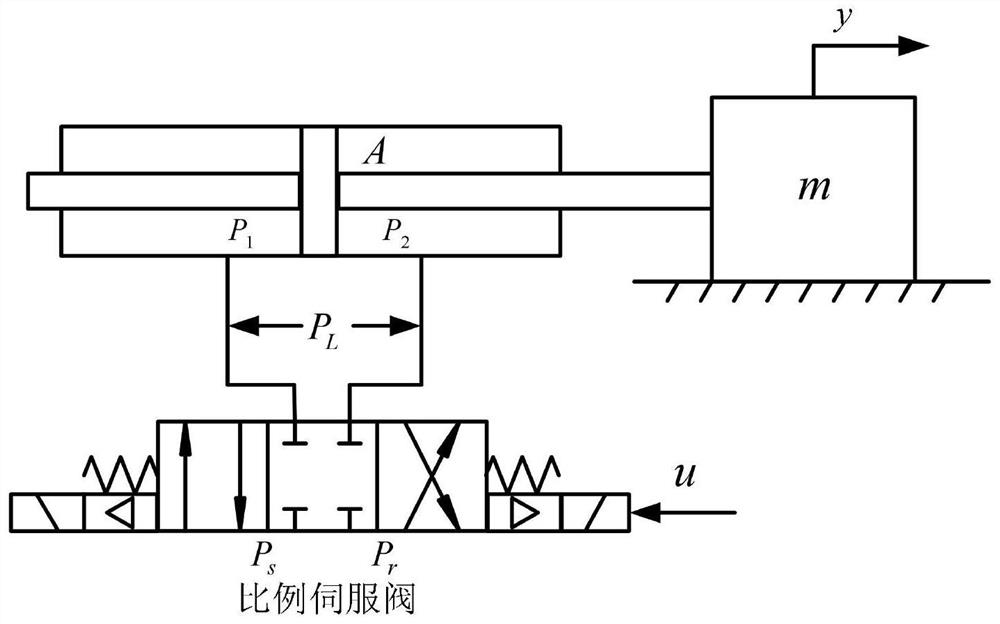

[0103] In order to evaluate the performance of the designed controller, the physical parameters of the electro-hydraulic proportional servo valve position axis control system in the simulation are shown in Table 1:

[0104] Table 1 System physical parameters

[0105] physical parameters Numerical value physical parameters Numerical value A(m 2 )

2×10 -4

beta e (Pa)

2×10 8

m(kg) 40 B(N·s / m) 80 C t (m 5 / (N s))

7×10 -12

k u (m / V)

4×10 -8

V 01 (m 3 )

1×10 -3

V 02 (m 3 )

1×10 -3

P s (MPa)

7 P r (MPa)

0 A f (N s / m)

10

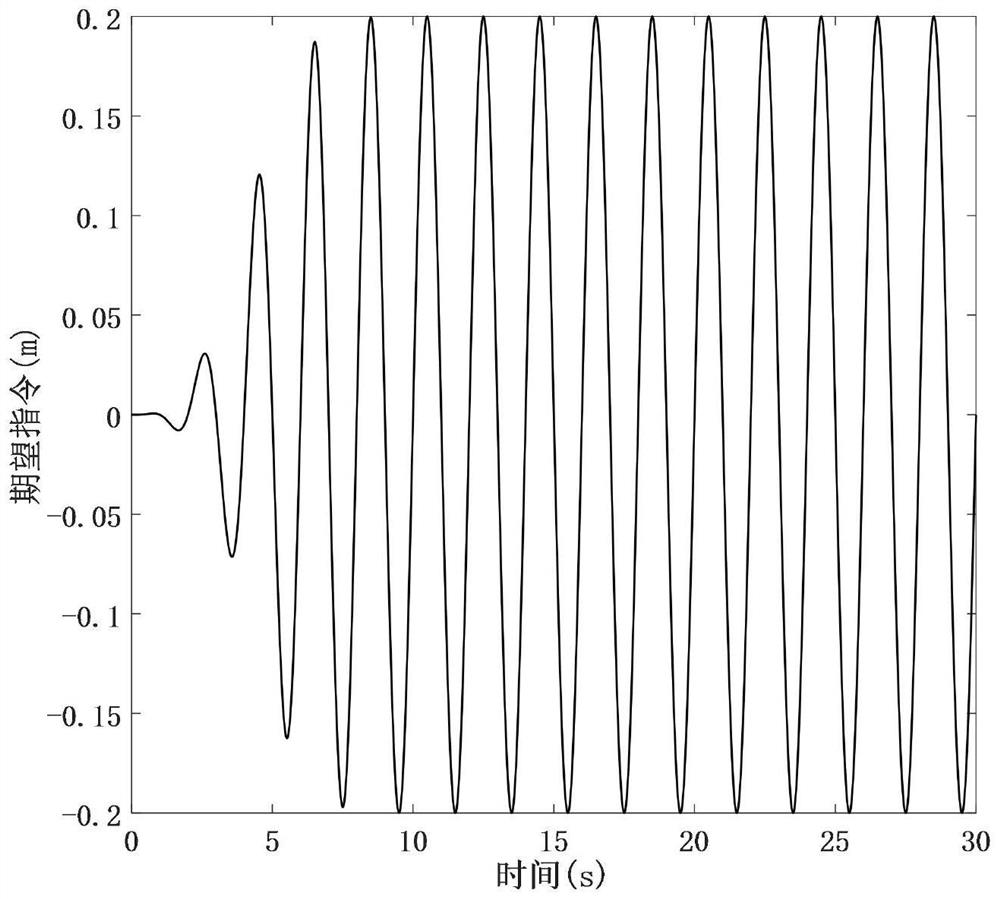

[0106] The expected instructions for a given system are The Coulomb friction shape function is S f (x 2 )=2arctan(1000x 2 ) / π.

[0107] In the simulation, the following controllers are used for comparison:

[0108] Electro-hydraulic proportional servo valve position axis control controller (UDORC) considering unknown dynamic co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com