Template self-adaptive transformation system of lining trolley and transformation method of template self-adaptive transformation system

A technology for lining trolleys and changing systems, which is applied in wellbore lining, tunnel lining, earth-moving drilling, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The technical solutions in the embodiments of the present application will be described below with reference to the accompanying drawings in the embodiments of the present application.

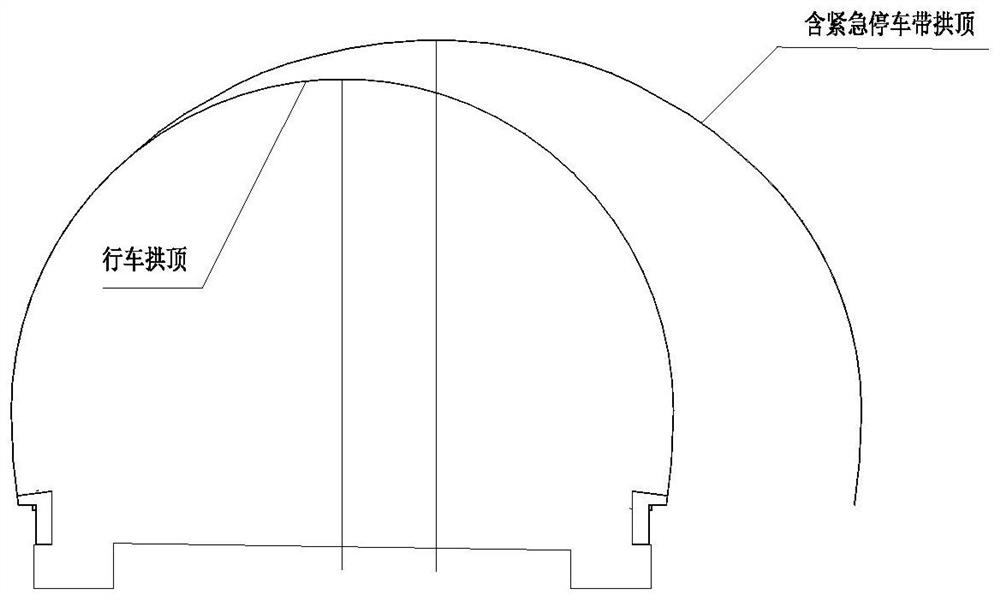

[0043] see figure 1 , because the entire section width of the vault of the emergency stop zone section is one more lane than the normal driving tunnel (normal lane section), the corresponding formwork section vault arc surface needs to be enlarged. Therefore, for these two working conditions (emergency parking zone section and normal lane section), the neutral plane of the trolley formwork does not overlap, and the trolley needs to move to the right as a whole to ensure that the left vault is basically the same.

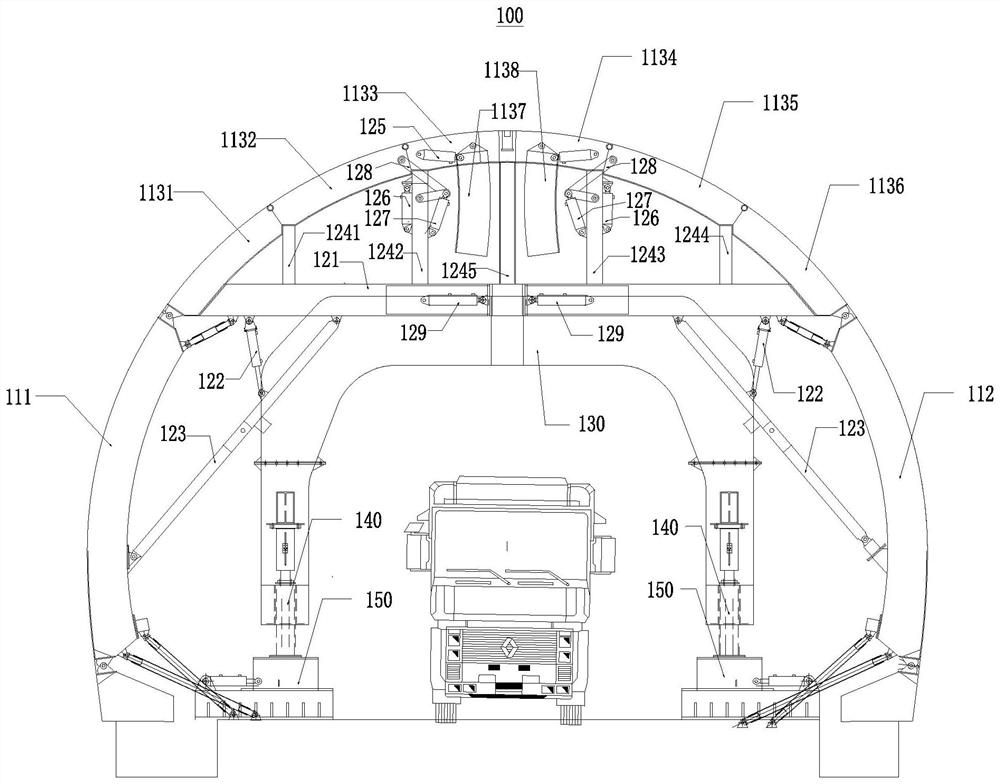

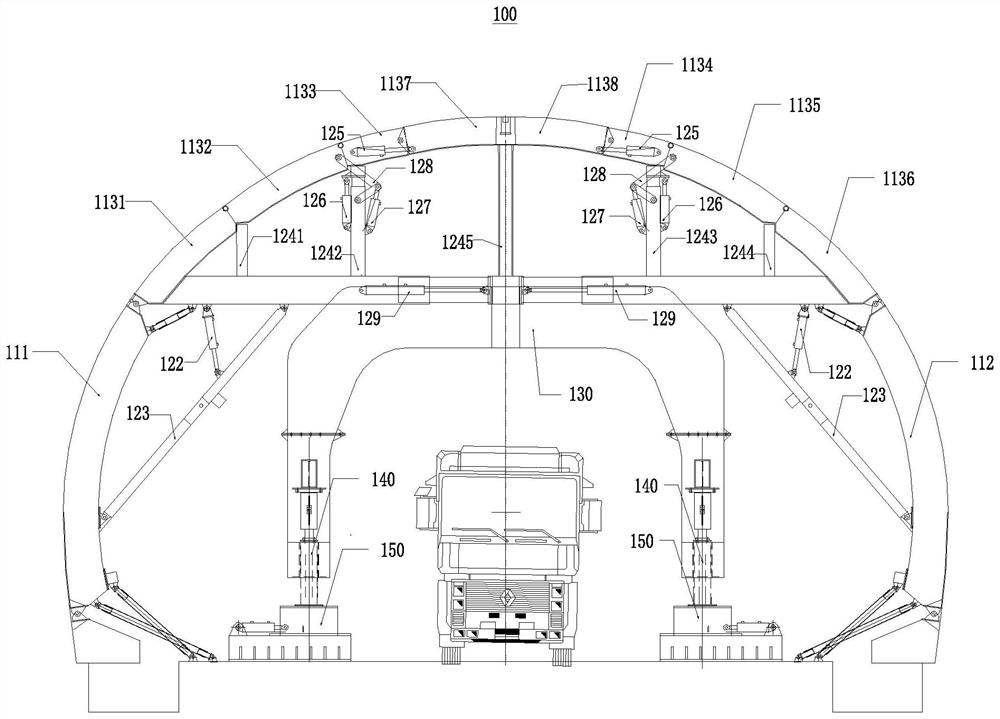

[0044] In order to facilitate the efficient construction of the emergency stop belt section and the conventional lane section, based on this, the embodiments of the present application provide a formwork adaptive conversion system for lining a trolley.

[0045] see figure 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com