Guide head mounting structure

A technology of installation structure and diversion head, which is applied in the direction of drill pipe, casing, measurement, etc., can solve the problems of drill collar and diversion head erosion, affect the service life, mud fluid turbulence, etc., and achieve uniform flow field and prolong Long service life, reduce the effect of fluid scouring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

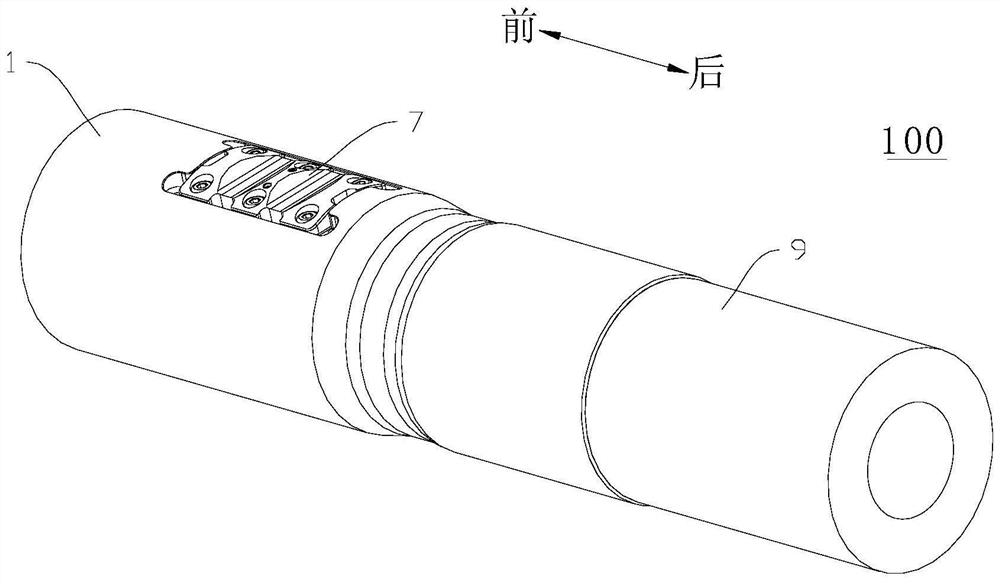

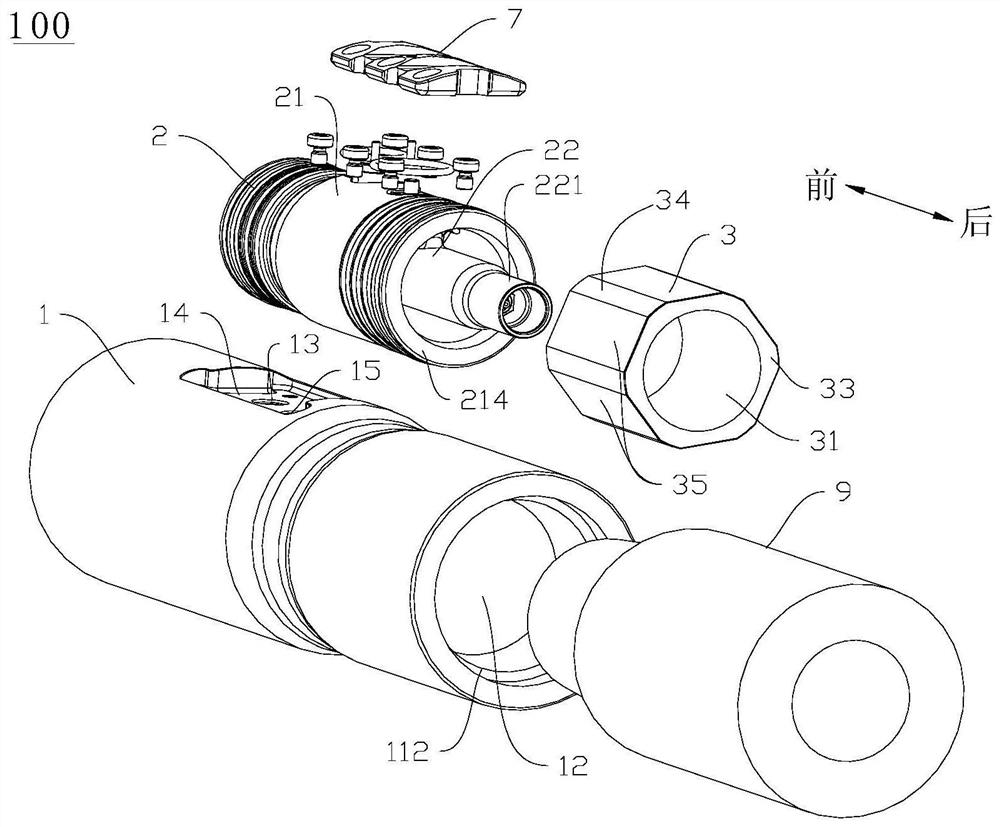

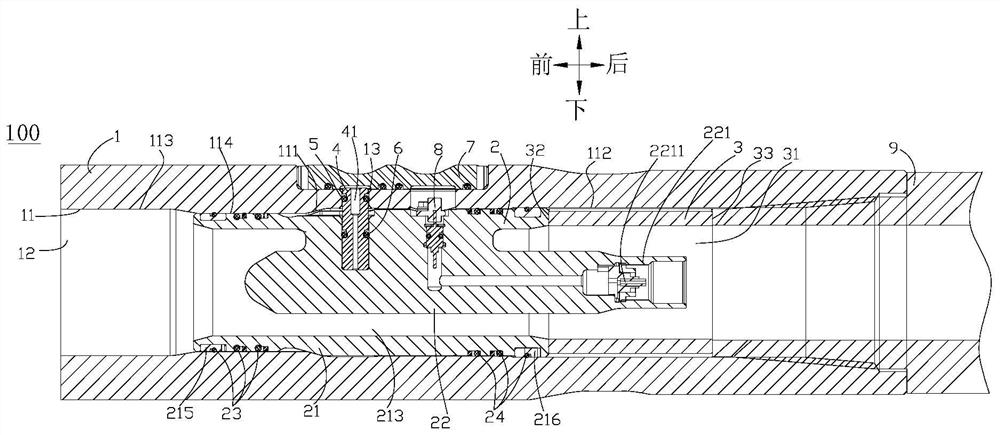

[0051] like Figure 1 to Figure 10 As shown, the guide head mounting structure 100 of the present embodiment is used for a 475-type LWD and directional logging tool, and the guide head mounting structure 100 is electrically connected to the docking piece. Of course, in other embodiments, the guide head mounting structure 100 can also be installed on other small-size LWD and directional logging instruments with an outer diameter less than 150 mm, or other guide head mounting structures 100 with the present invention can be used together Products used for mechanical support, sealing and electrical connection are not limited here.

[0052] like Figure 1 to Figure 4 As shown, the guide head installation structure 100 includes a drill collar 1, a guide head 2 and an elastic washer 3. The drill collar 1 is screwed with the docking housing 9, and the drill collar 1 is provided with a first direction extending in the first direction. A hole wall 11, the first hole wall 11 encloses ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com