Bridge reinforcing steel structure assembly

A steel structure and component technology, applied in bridge reinforcement, bridge, bridge construction, etc., can solve the problems of large bridge reconstruction, large engineering volume, weight increase of bridge body, etc., to improve bearing capacity, small engineering volume, oblique leg The effect of strength enhancement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

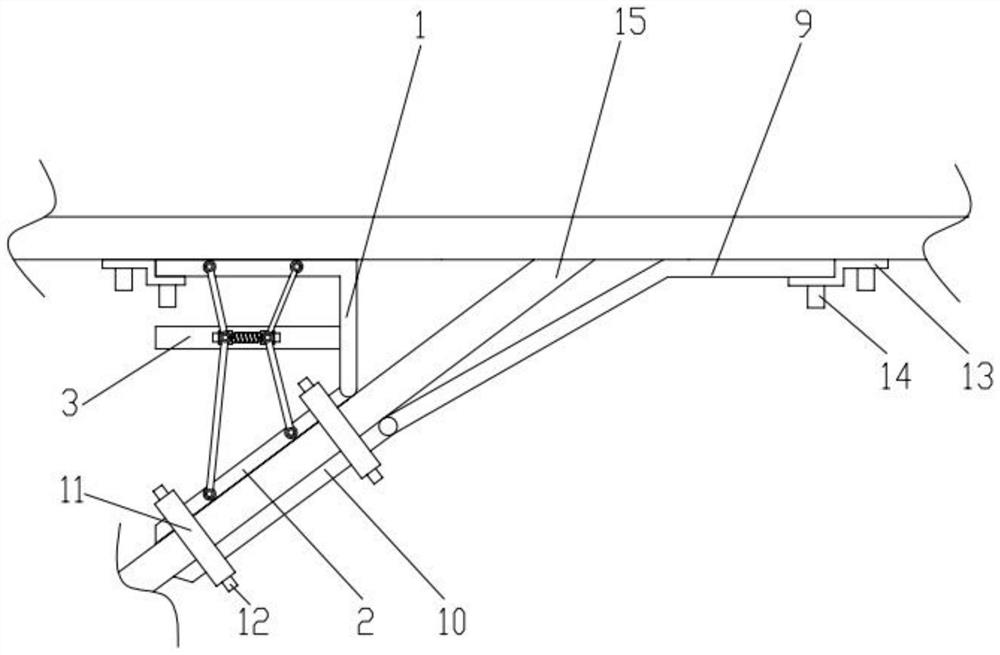

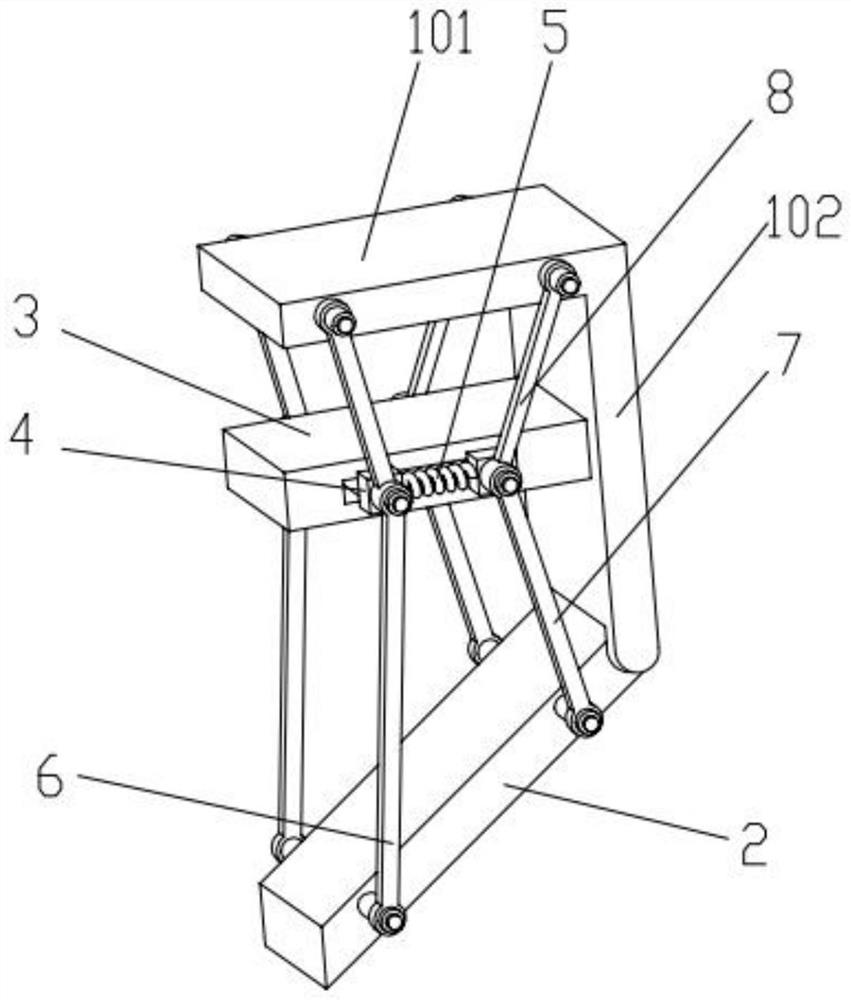

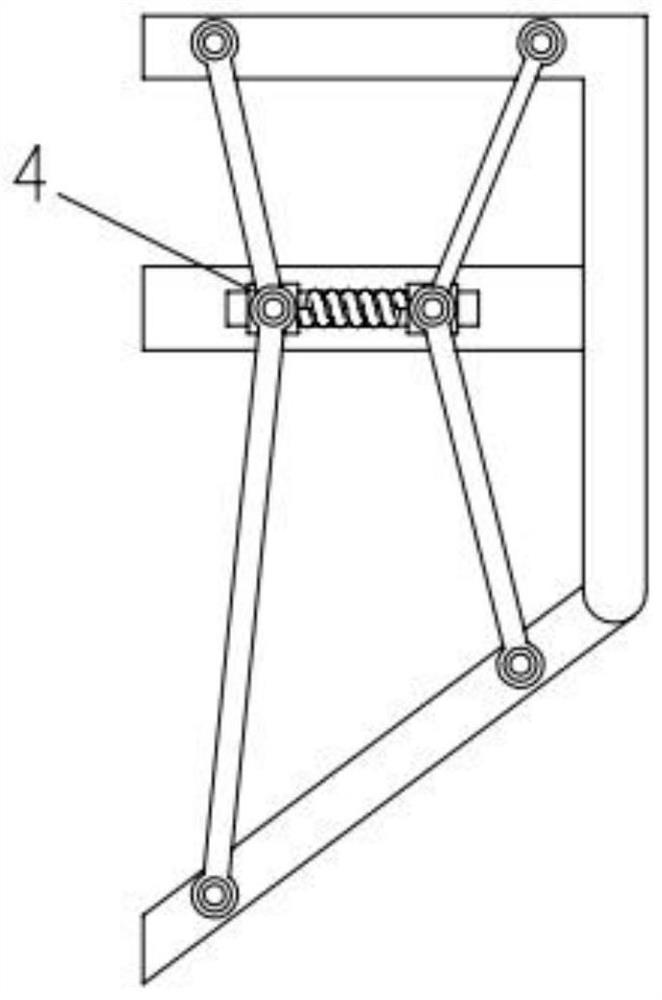

[0036] The invention provides a bridge reinforcement steel structure component, specifically as follows Figure 1-3 As shown, it includes a first reinforcement plate 1, a second reinforcement plate 2 and two adjustment assemblies.

[0037] The first reinforcing plate 1 and the second reinforcing plate 2 are located on one side of the inclined leg 15. The top of the upper end of the first reinforcing plate 1 is connected to the bottom of the bridge deck, the bottom of the second reinforcing plate 2 is connected to the top of the inclined leg 15, and the first reinforcing plate 1 is horizontal. The cross section is L-shaped, the first reinforcing plate 1 includes a horizontal plate 101 and a vertical plate 102 , and one end of the second reinforcing plate 2 is hinged to the lower end of the vertical plate 102 of the first reinforcing plate 1 . When the angle of the inclined leg 15 changes, the angle of the second reinforcing plate 2 can be adjusted so that the second reinforcing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com