Pickling device for high-strength rivet wire

A kind of pickling device and high-strength technology, which is applied to the pickling device of high-strength rivet wire, and the field of wire pickling, can solve the problems of acid fog permeating the workshop, affecting the health of workers, and waste of raw materials, so as to reduce waste of raw materials and realize The effect of waste utilization and high flexibility of rotation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

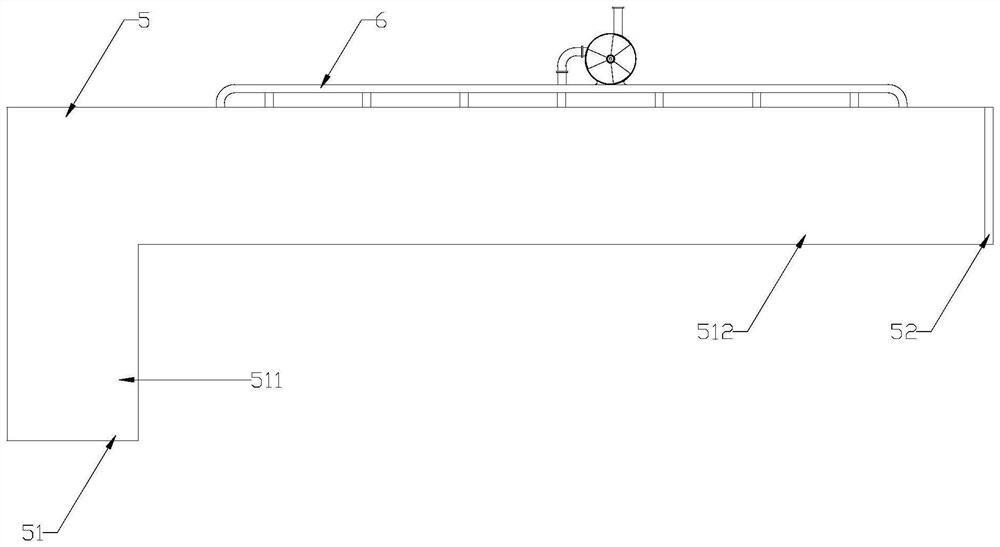

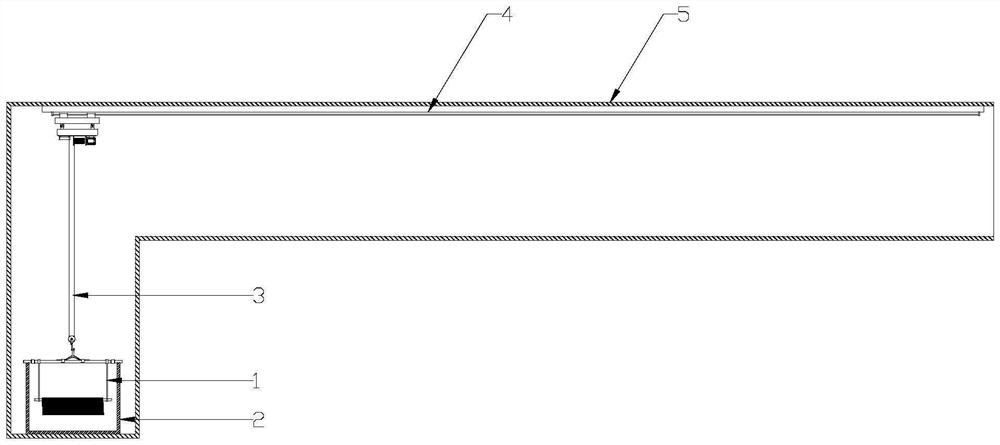

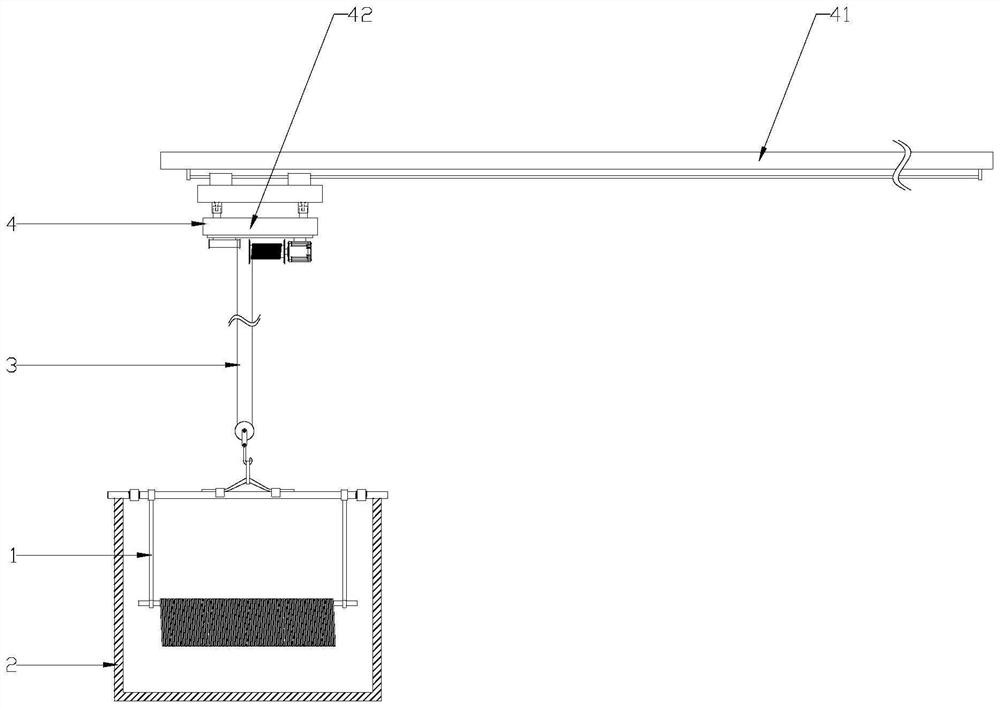

[0022] see Figure 1 to Figure 6 , the present invention is a pickling device for high-strength rivet wire, including a support frame 1, a pickling tank 2, a lifting mechanism 3, a translation mechanism 4, a casing 5, a ventilation mechanism 6, a lye pool and a controller, the said The casing 5 includes a casing 51 and a casing door 52 . The casing 51 includes a first casing section 511 arranged vertically and a second casing section 512 arranged horizontally. The pickling tank 2 is located at the first casing section 511 . At the bottom of the inner cavity, the left end of the second shell segment 512 communicates with the top end of the first shell segment 511 and the right end is provided with a discharge port, the discharge port is closed by the shell door 52, and the translation mechanism 4 is installed in the The top wall of the inner cavity of the second shell segment 512 can drive the lifting mechanism 3 to move horizontally, left and right or back and forth. Move ver...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com