Automatic folding and arranging device for textiles

A finishing device and technology for textiles, applied in the field of textile folding, can solve the problems of textile flattening, textile offset, low folding efficiency, etc., and achieve the effects of facilitating longitudinal folding, ensuring folding effect, and ensuring flatness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The embodiments of the present invention are described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways as defined and covered by the claims.

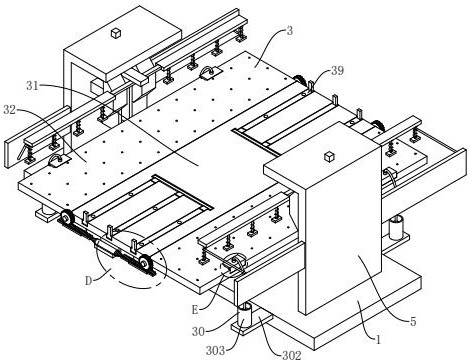

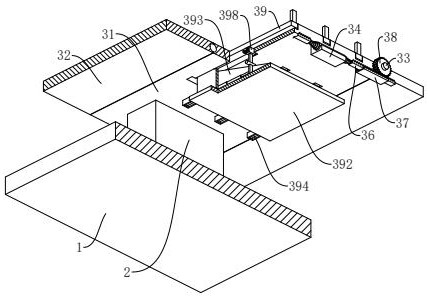

[0034] The following describes an automatic folding and finishing device for textiles according to an embodiment of the present invention with reference to the accompanying drawings. see figure 1 and image 3 , an automatic folding and finishing device for textiles, comprising a base 1, a support base 2, a support unit 3 and a smoothing unit 5, the base 1 is placed horizontally, and a support base 2 is installed in the middle of the upper end of the base 1.

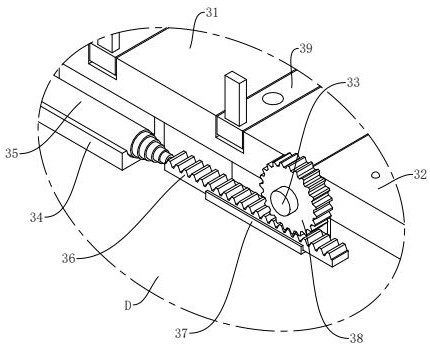

[0035] see figure 1 , figure 2 and image 3 , the support unit 3 includes a horizontal plate 31, a folding plate 32, a rotating shaft 33, a positioning frame 34, a two-way cylinder 35, a rack plate 36, a fixing frame 37, a linkage gear 38, a folding assembly 39 and a limit assembly 30, wher...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com