Material box warehousing method, device and equipment and storage medium

A material box and inventory technology, which is applied in the field of intelligent warehousing, can solve the problems of long moving path, material box accumulation at the feeder, affecting storage efficiency, etc., so as to reduce the moving distance, reduce crowding, and improve storage efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

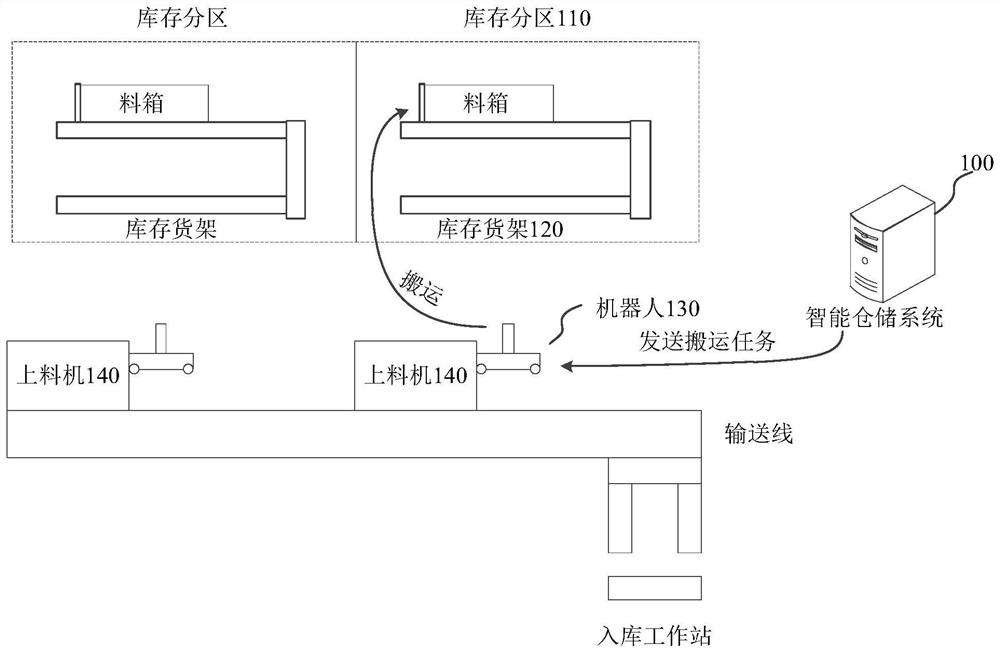

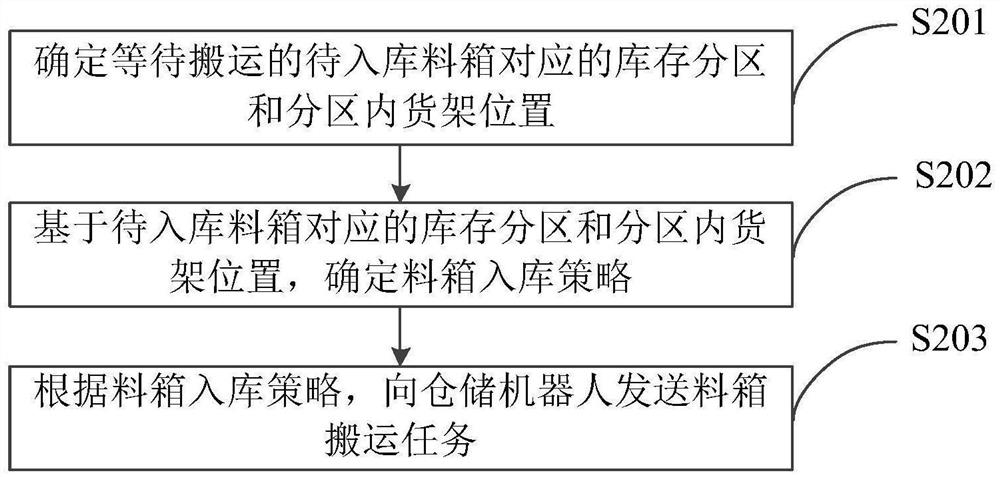

[0065] Here will explain the examples of the examples in detail, and the examples are expressed in the attached figure. The description below involves the attached picture, unless otherwise indicated, the same number in different attached figures represents the same or similar elements. The embodiments described in the following examples do not represent all embodiments consistent with this disclosure. Instead, they are just aspects and methods that are consistent with some aspects of the disclosure as described in the possessive request.

[0066] The following examples are based on the specific embodiments to explain the technical solutions of this disclosure and how this disclosed technical solution solve the above technical issues. The following specific embodiments can be combined with each other, and the same or similar concepts or processes may not be repeated in certain embodiments. Below will be described in conjunction with the attachment.

[0067] In the existing warehou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com