Compound enzyme preparation for liquid oat base material and use method of compound enzyme preparation

A technology of compounding enzymes and oats, which is applied in applications, dairy products, milk substitutes, etc., can solve the problems of low utilization rate of raw material nutrients and unsatisfactory flavor, and achieve improved taste and function, better taste, and improved Effect of Enzymatic Efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

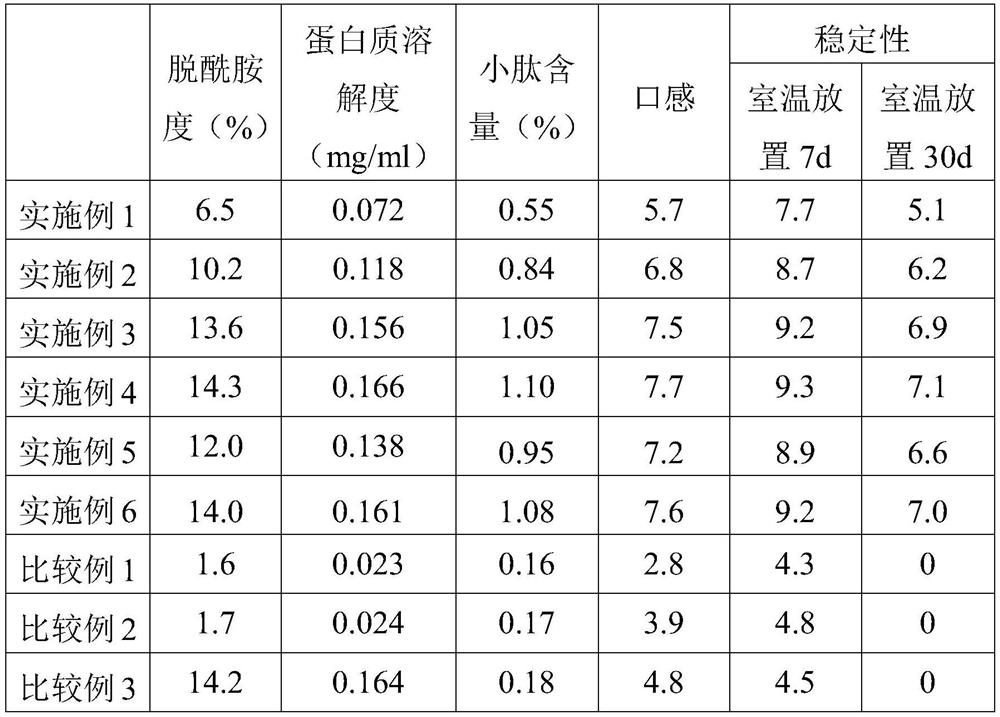

Examples

Embodiment 1

[0023] This embodiment provides a compound enzyme preparation for liquid oat base material, including 15% protein glutaminase, 15% α-amylase, 10% neutral protease, 8% Glucoamylase, 5% pullulanase, 5% sodium chloride and 42% corn starch are mixed uniformly to obtain a compound enzyme preparation.

[0024] The above-mentioned composite enzyme preparation is used to produce liquid oat base material, and the concrete steps are as follows:

[0025] Weigh 20kg of oat flour, add 980kg of water, stir to be warmed up to 55°C to obtain an oat aqueous solution, based on the weight of the oat raw material, add a compound enzyme preparation to the oat aqueous solution in an amount of 0.1% for enzymolysis, and control the pH value to be about 7.0 , the stirring speed is 200 rpm, and after the reaction for 180 min, the temperature is raised to 90° C. to inactivate the enzyme for 10 min to complete the reaction to obtain a liquid oat base material.

[0026] In order to investigate the modifi...

Embodiment 2

[0029] Use compound enzyme preparation in embodiment 1 to produce liquid oat base material, and concrete steps are as follows:

[0030] Weigh 20kg of oat flour, add 980kg of water, stir to be warmed up to 55°C to obtain an oat aqueous solution, based on the weight of the oat raw material, add a compound enzyme preparation to the oat aqueous solution in an amount of 0.2% for enzymolysis, and control the pH value to be about 7.0 , the stirring speed is 200 rpm, and after the reaction for 180 min, the temperature is raised to 90° C. to inactivate the enzyme for 10 min to complete the reaction to obtain a liquid oat base material.

[0031] In order to investigate the modification effect of the compound enzyme preparation on the protein of liquid oat base material, the indexes of the prepared liquid oat base material were tested. T5298 measures the content of small peptides. 10 people were randomly selected to score the taste and stability of the liquid oat base material through t...

Embodiment 3

[0034] Use compound enzyme preparation in embodiment 1 to produce liquid oat base material, and concrete steps are as follows:

[0035] Weigh 20kg of oat flour, add 980kg of water, stir to be warming up to 55°C to obtain an oat aqueous solution, based on the weight of the oat raw material, add a compound enzyme preparation to the oat aqueous solution in an amount of 0.5% for enzymolysis, and control the pH value to be about 7.0 , the stirring speed is 200 rpm, and after the reaction for 180 min, the temperature is raised to 90° C. to inactivate the enzyme for 10 min to complete the reaction to obtain a liquid oat base material.

[0036]In order to investigate the modification effect of the compound enzyme preparation on the protein of liquid oat base material, the indexes of the prepared liquid oat base material were tested. T5298 measures the content of small peptides. 10 people were randomly selected to score the taste and stability of the liquid oat base material through t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com