Egg tart skin and manufacturing process thereof

A manufacturing process and egg tart skin technology, applied in the field of egg tart skin and its manufacturing process, can solve the problems of crispy taste and other problems, and achieve the effects of improving air retention, improving dessert volume and honeycomb structure, and moderate sweetness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1-3

[0044] A kind of emulsifier of preparation example 1-3, its each raw material and each raw material consumption are as shown in table 1, and its preparation step is as follows:

[0045] Each raw material was weighed according to the amount in Table 1, and then each raw material was stirred uniformly to obtain an emulsifier.

[0046] Each raw material of the emulsifier of table 1 preparation example 1-3 and each raw material consumption (kg)

[0047] Preparation Example 1 Preparation Example 2 Preparation Example 3 calcium lactate 8 10 12 Sucrose fatty acid ester 6 5 4 Distilled monoglycerides 2 3 4

Embodiment 1-4

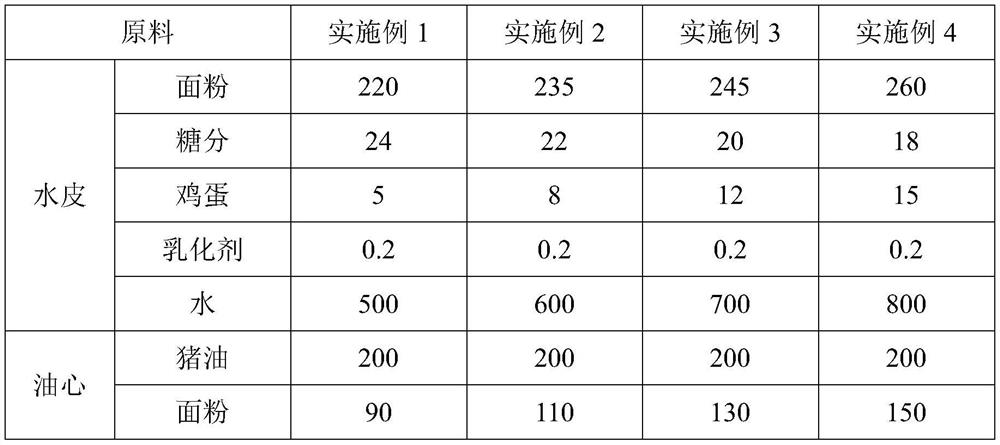

[0050] A kind of egg tart crust of embodiment 1-4, its each raw material and each raw material consumption are as shown in table 2, and its preparation step is as follows:

[0051] S1. Weigh the raw materials according to the proportions, blend flour, sugar, eggs, emulsifier and water, and then place them at a temperature of 6 °C for 45 minutes to obtain a water skin; blend lard and flour, and then heat at 6 °C Under the temperature conditions of 40min, the oil core was obtained;

[0052] S2. Roll the water skin and the oil core into a thickness of 1 cm respectively, and wrap the oil core with the water skin to obtain the first dough;

[0053] S3. Roll the first dough into a first dough with a thickness of 1 cm, and then fold the first dough to obtain a second dough; roll the second dough into a second dough with a thickness of 1 cm, and then fold the second dough, Obtain a third dough; grind the third dough into a third dough with a thickness of 1 cm, and then fold the third...

Embodiment 5

[0061] A kind of egg tart crust, the difference from Example 3 is that the added emulsifier comes from Preparation Example 2, and the remaining steps are the same as those in Example 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com