Calibration method and device for lubricating oil pollution degree sensor

A calibration method and calibration device technology, applied in the field of sensor calibration, can solve problems such as long operation time, decreased accuracy, and low automation level, and achieve the effects of high automation, improved accuracy, and high calibration efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

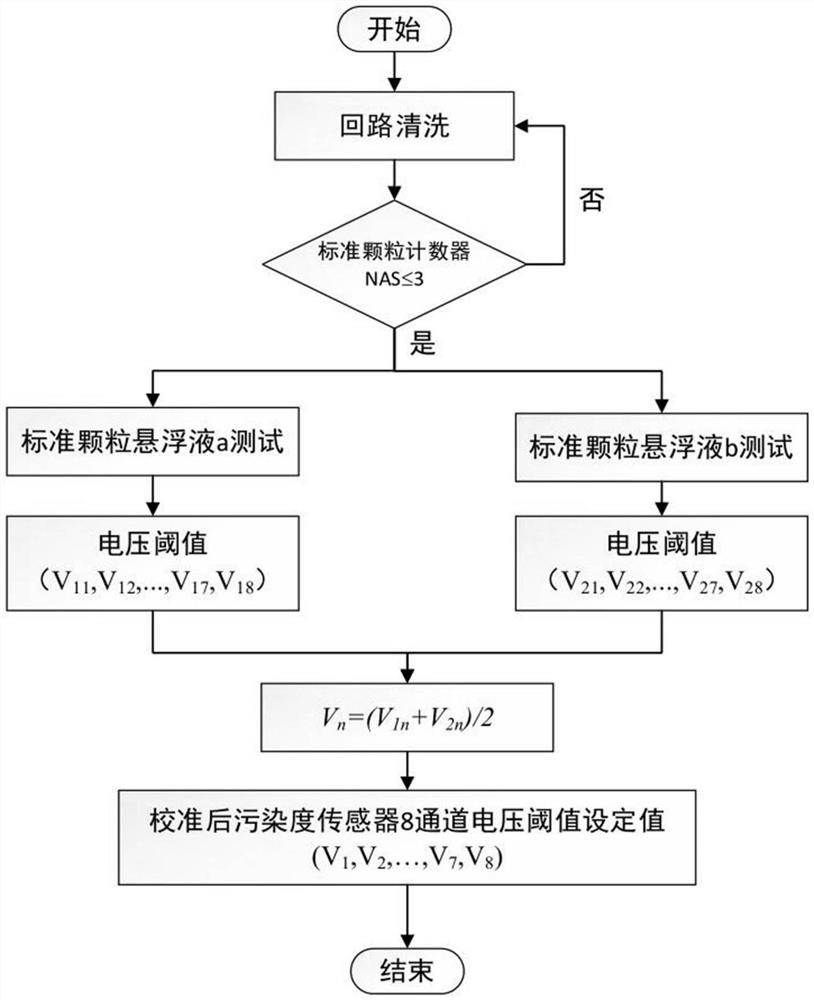

[0041] A method for calibrating a lubricating oil contamination degree sensor, comprising: calculating the standard voltage thresholds of the lubricating oil contamination degree sensor to be calibrated under a first standard particle suspension and a second standard particle suspension, and denoting it as the first standard voltage threshold and the second standard voltage threshold; calculate the average value of the first standard voltage threshold and the second standard voltage threshold, obtain the calibrated voltage threshold of the lubricating oil pollution degree sensor to be calibrated, and complete the calibration of the lubricating oil pollution degree sensor.

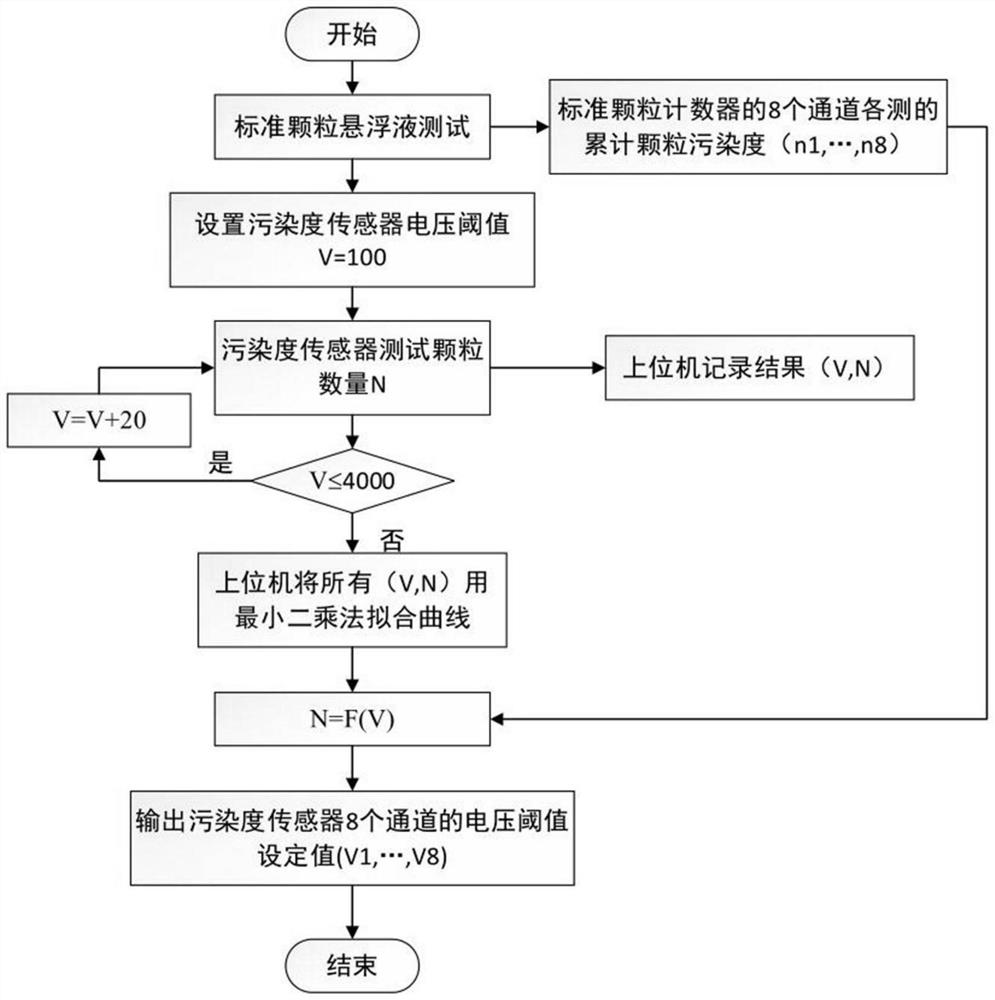

[0042] The method for calculating the standard voltage threshold of the lubricating oil contamination sensor to be calibrated under the first standard particle suspension includes:

[0043] 1. Obtain the cumulative particle pollution degree of the first standard particle suspension detected by the lubricatin...

Embodiment 2

[0062] Based on the method for calibrating a lubricating oil contamination degree sensor described in Embodiment 1, this embodiment provides a calibration device for a lubricating oil contamination degree sensor, such as figure 1 As shown, it includes: the lubricating oil pollution degree sensor 12 to be calibrated, the standard lubricating oil pollution degree sensor 10, the first standard particle suspension 1, the second standard particle suspension 3, the peristaltic pump 7 and the host computer 11; the host computer 11 respectively Connect with the lubricating oil pollution degree sensor 12 to be calibrated and the standard lubricating oil pollution degree sensor 10; the inlet of the peristaltic pump 7 is respectively connected to the first standard particle suspension 1 and the second standard particle suspension 3 through the pipeline, and the outlet of the peristaltic pump 7 passes through The pipeline is connected to the pressure regulator valve 8, the defoaming device...

Embodiment 3

[0090] Based on Embodiment 1 and Embodiment 2, this embodiment calibrates a certain lubricating oil pollution degree sensor, so that the calibrated lubricating oil pollution degree sensor reaches the accuracy of the standard lubricating oil pollution degree sensor.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com