Rolling type auxiliary stress floating mechanism

A floating mechanism, rolling technology, used in slitting machinery, propulsion, earth-moving drilling, etc., can solve the problems of wear of sliding shoes and walking wheels, complex working conditions on site, etc., to achieve extended service life, good versatility, The effect of reducing wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

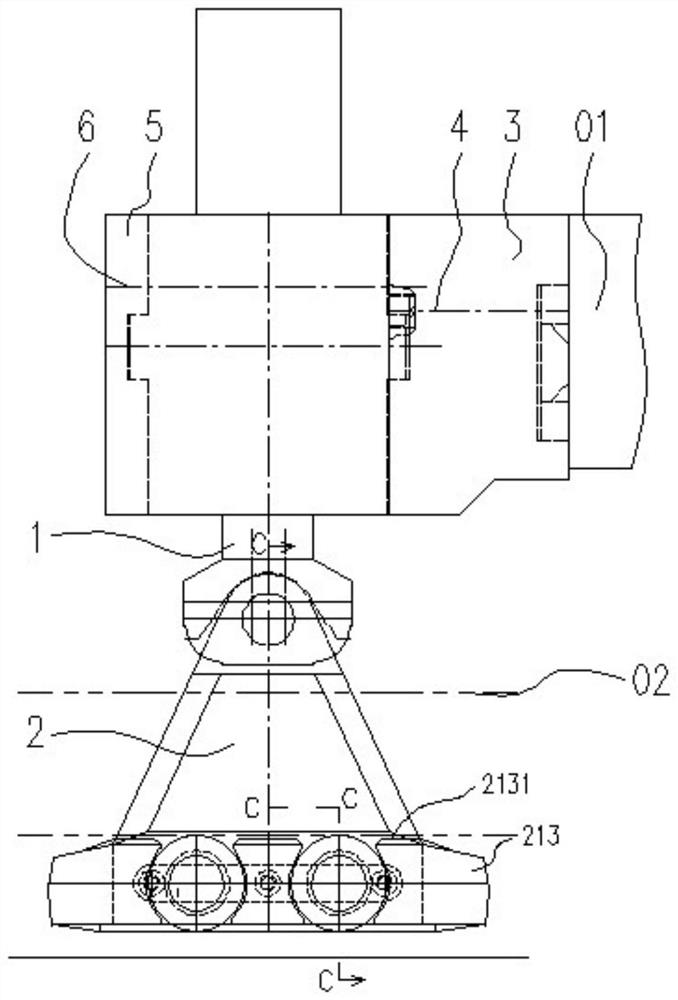

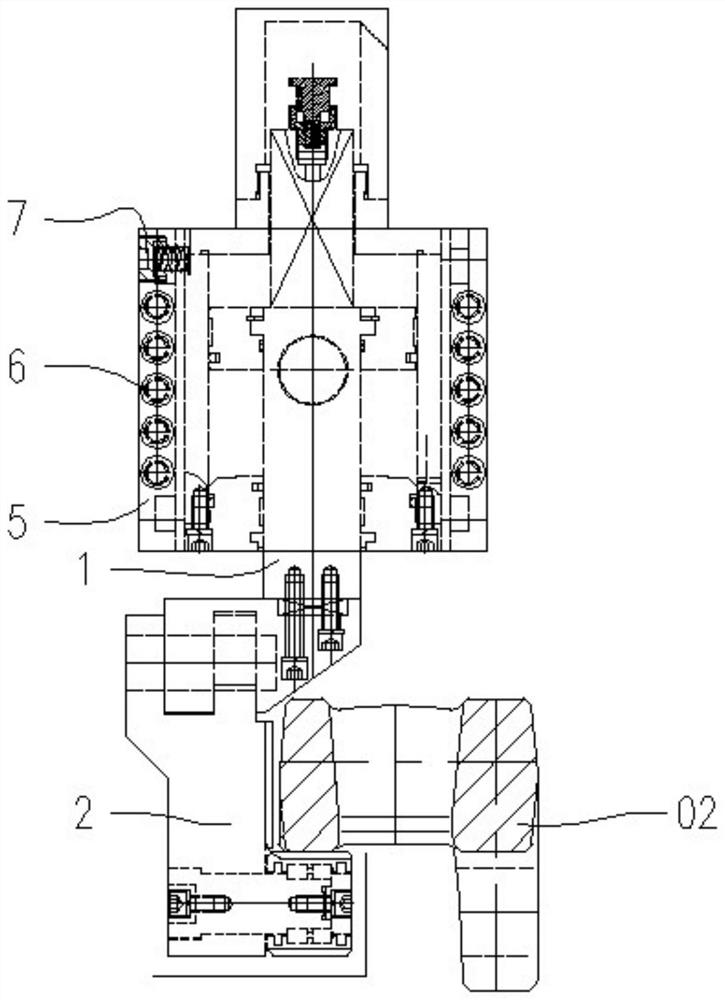

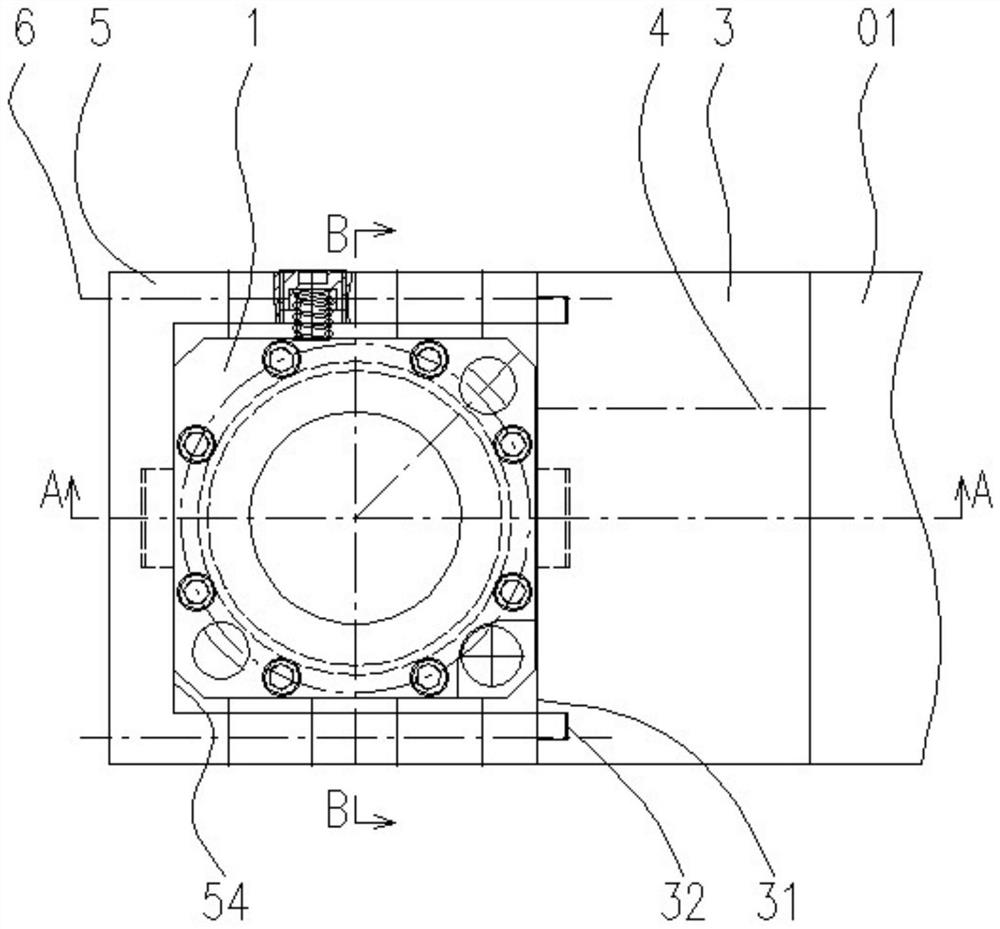

[0048] like Figure 1-13 It shows that the present invention has disclosed a rolling -type auxiliary stress floating mechanism, including lifting device 1. Rolling wheel device 2 and framework. Inside. The lifting device uses a dual -rod piston cylinder, the cylinder cylinder 11 of the piston cylinder is installed in the frame, and there is a gap between the outer wall of the cylinder tube and the frame. The upper and lower ends of the Pistons 13 extend to the outside of the frame. The piston rod is equipped with a airway, the upper end of the airway is on the upper end of the piston rod, the lower end of the airway is on the outer column of the piston rod, and the lower edge of the piston 14 is close to the height direction. Or all is below the piston, that is, the inferior cavity of the tract is connected to the lower cavity of the piston cylinder. The upper cavity of the piston cylinder can be connected to the atmosphere through the frequent ventilation channel. The upper cavity...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com