In-situ composite aluminum ferrite water treatment agent as well as preparation method and application method thereof

An in-situ composite and treatment agent technology, applied in the direction of flocculation/sedimentation water/sewage treatment, sterilization/microdynamic water/sewage treatment, sustainable biological treatment, etc., can solve the problem of small, single, ferric acid Solve problems such as poor salt stability, achieve good bactericidal properties, good flocculation performance, and good storage stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

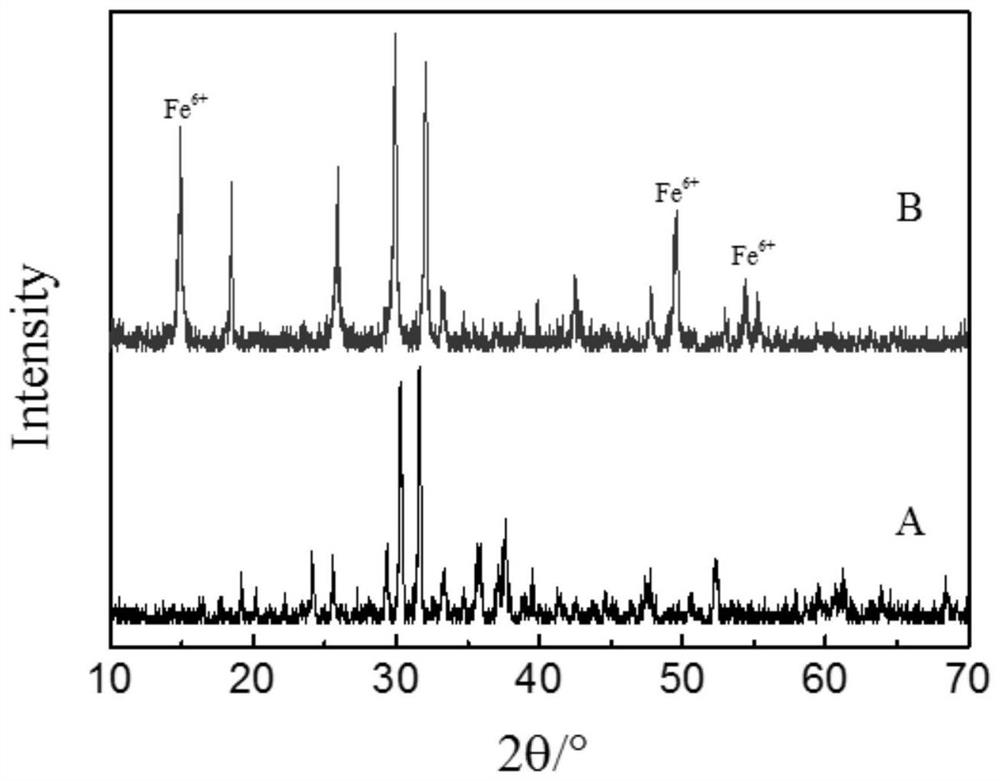

Image

Examples

Embodiment 1

[0022] A preparation method of an in-situ composite aluminum ferrite water treatment agent, comprising the following steps:

[0023] Add 200 g (1.2330 mol) of ferric chloride to 300 g of water, stir evenly, add 39 g (0.5 mol) of aluminum hydroxide, beat evenly to obtain a mixture, then add 40 g (1 mol) of sodium hydroxide, and heat up to 75°C Dissolve the insoluble matter in the mixture uniformly, keep the temperature for 1 hour; then add 10 g (0.1343 mol) of sodium hypochlorite, the material turns yellowish brown, and continue stirring until the material turns into a purple-red translucent solution, that is, the in-situ composite aluminum ferrite sodium brine is obtained Treatment agent, the product name is denoted as Fe(VI)-SA.

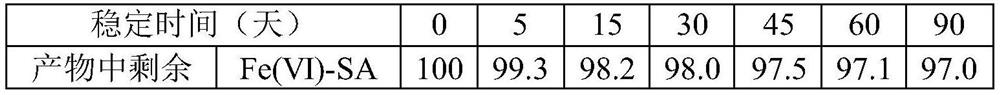

[0024] The liquid product of this example can be stored stably for at least 3 months at a temperature not higher than 40° C. without precipitation.

Embodiment 2

[0026] A preparation method of an in-situ composite aluminum ferrite water treatment agent, comprising the following steps:

[0027] Add 200 g (1.2330 mol) of ferric chloride (III) to 300 g of water, stir evenly, add 78 g (1 mol) of aluminum hydroxide, beat evenly to obtain a mixed material, then add 120 g (3 mol) of sodium hydroxide, heat up to 80°C to make The insoluble matter in the mixture was uniformly dissolved and kept for 1.5h; then, after adding 45g (0.4970mol) of potassium hypochlorite, the material turned yellow-brown, and continued stirring until the material turned into a purple-red translucent solution, that is, the in-situ composite sodium aluminum ferrite was obtained. Brine treatment agent, the product name is denoted as Fe(VI)-SA.

[0028] The liquid product of this example can be stored stably for at least 3 months at a temperature not higher than 40° C. without precipitation.

Embodiment 3

[0030] A preparation method of an in-situ composite aluminum ferrite water treatment agent, comprising the following steps:

[0031] Add 400 g (2.4660 mol) of ferric chloride (III) to 300 g of water, stir evenly, add 102 g (1 mol) of pseudo-boehmite, beat evenly to obtain a mixture, then add 100 g (2.5 mol) of sodium hydroxide, and heat up to The insoluble matter in the mixture was dissolved evenly at 70°C, and kept for 2 hours; then, after adding 74.5 g (1 mol) of sodium hypochlorite, the material turned yellow-brown, and continued stirring until the material turned into a purple-red translucent solution, that is, the in-situ composite aluminum ferric acid was obtained. Sodium brine treatment agent, the product name is denoted as Fe(VI)-SA.

[0032] The liquid product of this example can be stored stably for at least 3 months at a temperature not higher than 40° C. without precipitation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com