Swash plate assembly with integrated electric motor

A swash plate, electric motor technology, applied in the direction of electric components, electrical components, rotorcraft, etc., can solve the problem of lack of integration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

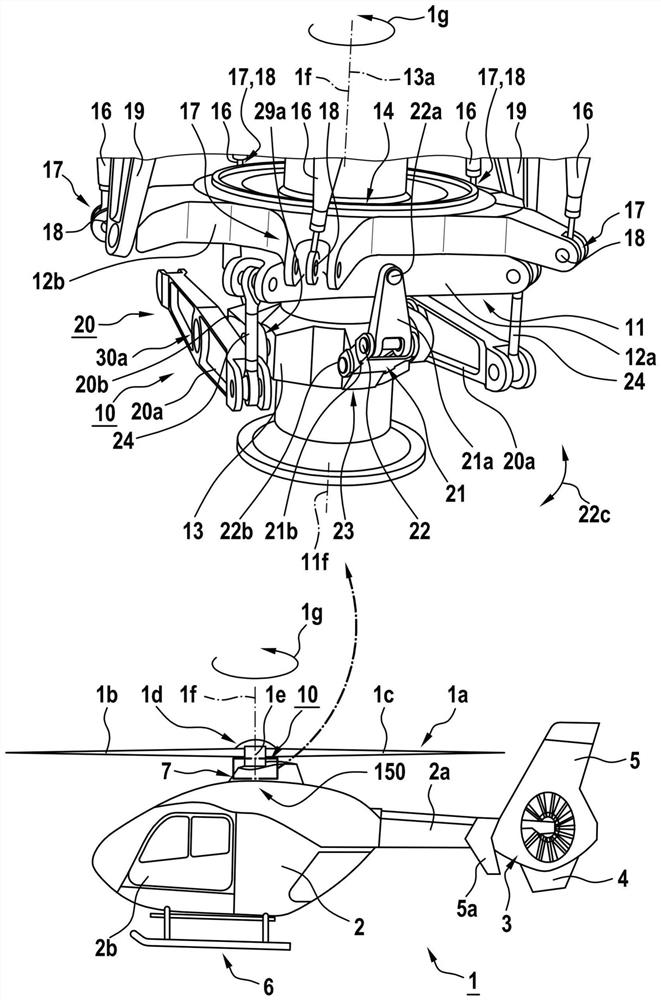

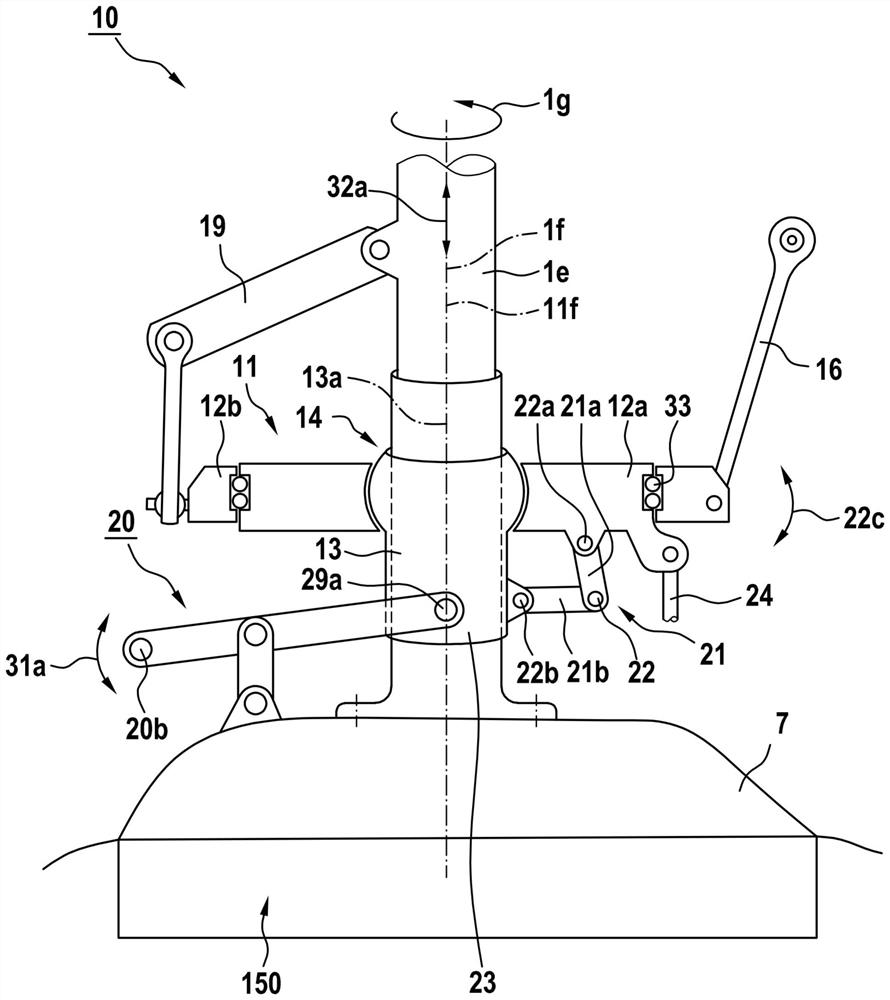

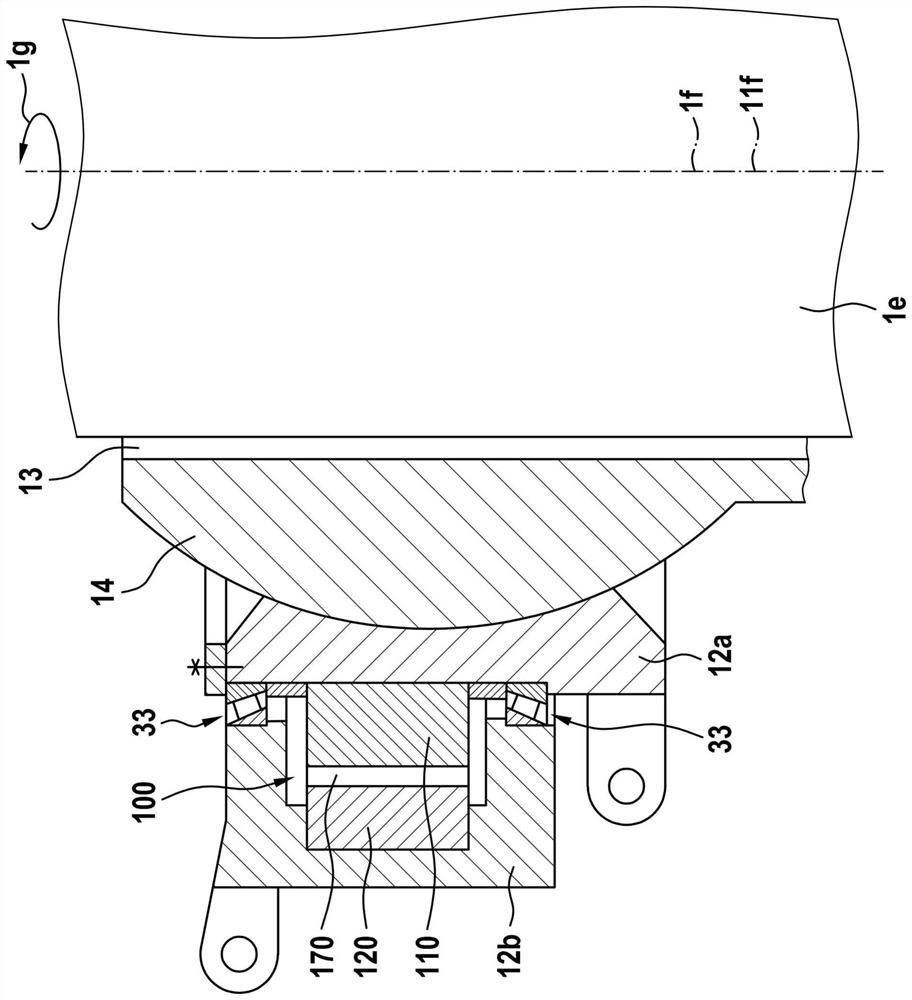

[0048] figure 1 An illustrative rotary wing aircraft 1 is shown having a fuselage 2 connected to a landing gear 6, the fuselage 2 defining a tail boom 2a and a nacelle 2b. The rotary wing aircraft 1 comprises at least one multi-blade rotor 1a for providing lift and forward or backward thrust during operation.

[0049] At least one multi-blade rotor 1a comprises rotor blades 1b, 1c, which are mounted on rotor shaft 1e at associated rotor hub 1d. The rotor shaft 1e rotates in the rotational direction 1g about the associated rotor axis 1f in the operation of the rotorcraft 1 .

[0050] Illustratively, rotary wing aircraft 1 may include a combustion engine 150 that drives rotor shaft 1e. Combustion engine 150 may be an internal combustion engine 150 in which combustion in the combustion chamber applies direct forces to some components of the engine and from these components to rotor shaft 1e.

[0051] For example, the rotary wing aircraft 1 is realized as a helicopter comprisin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com