Charging gun and charging socket matched with same

A technology of charging guns and pins, which is applied in the field of charging guns, can solve the problems of increased wear, melting and welding, and the reduction of effective electrical contact area, so as to improve the durability of plugging and unplugging, ensure the electrical contact area, and ensure the convenience of plugging and unplugging sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

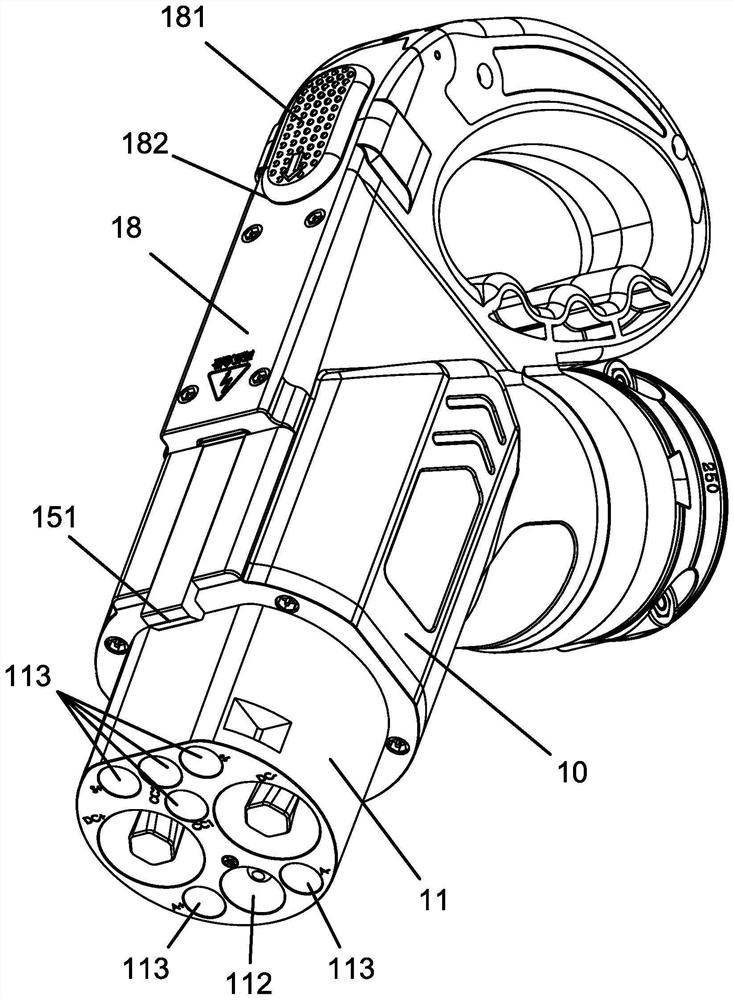

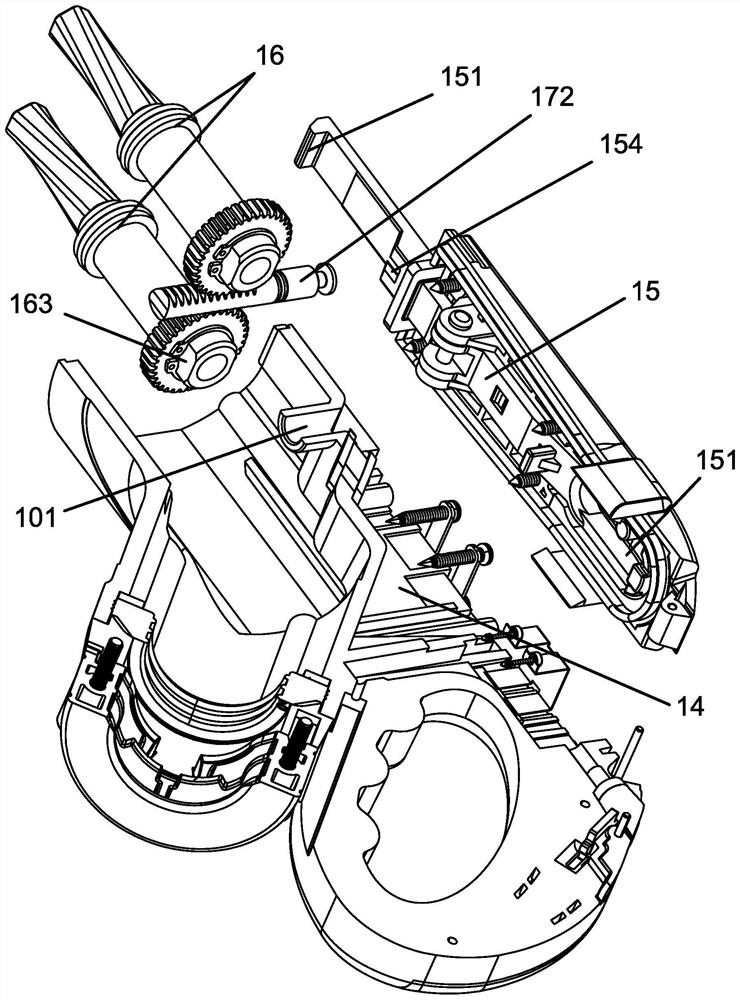

[0053] refer to Figure 1 to Figure 8 ,like Image 6 and Figure 7 The shown charging socket adapted to the charging gun is used for adapting to the charging gun of Embodiment 1, and includes a base 20, and the base 20 is provided with a socket 21 for inserting the socket 11, The socket 21 is provided with a locking groove 211 adapted to the locking hook 151; the socket 21 is provided with a conductive sleeve 22, the conductive sleeve 22 is provided with a rotary locking hole 221, and the inner wall of the rotary locking hole 221 It is polygonal and twists helically in the circumferential direction of the conductive sleeve 22, while the cross-sectional contour of the end facing the charging gun is larger than the cross-sectional contour of the end away from the charging gun; when the charging gun is inserted, the locking section 161 is inserted into the rotary lock The tightening hole 221 is then locked with the rotating locking hole 221 by screwing in and rotating; when the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com