Connector and electronic equipment

A technology of connectors and grounding terminals, which is applied in the field of connectors and electronic equipment, and can solve problems such as high frequency resonance and poor high-speed transmission effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

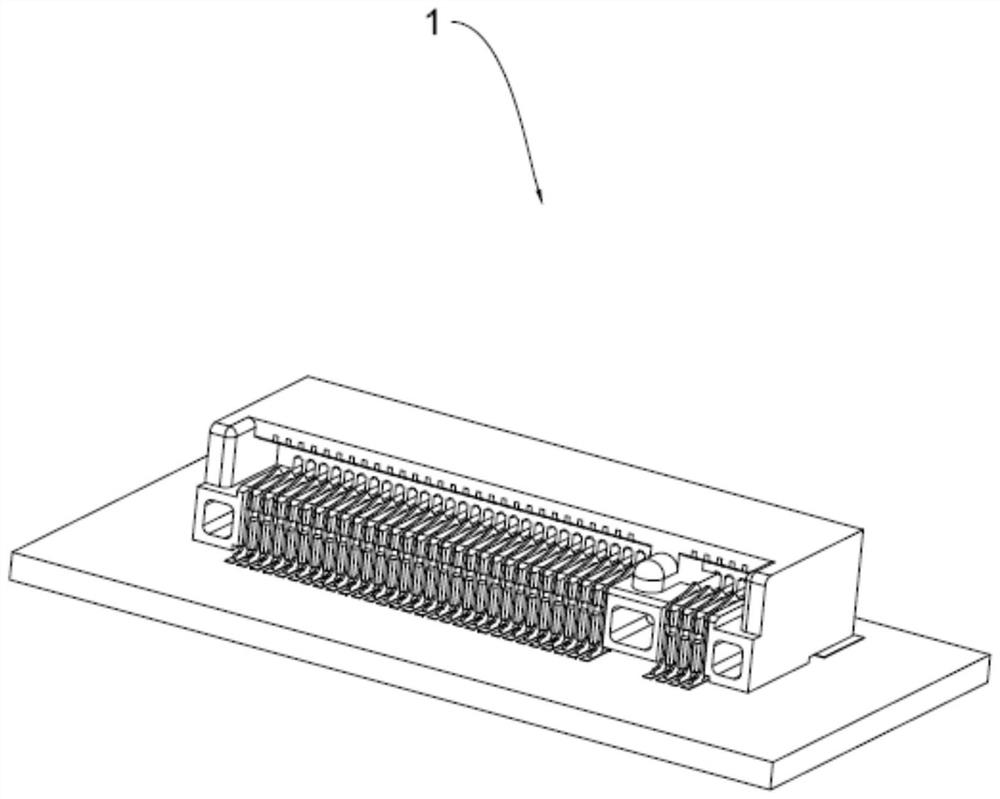

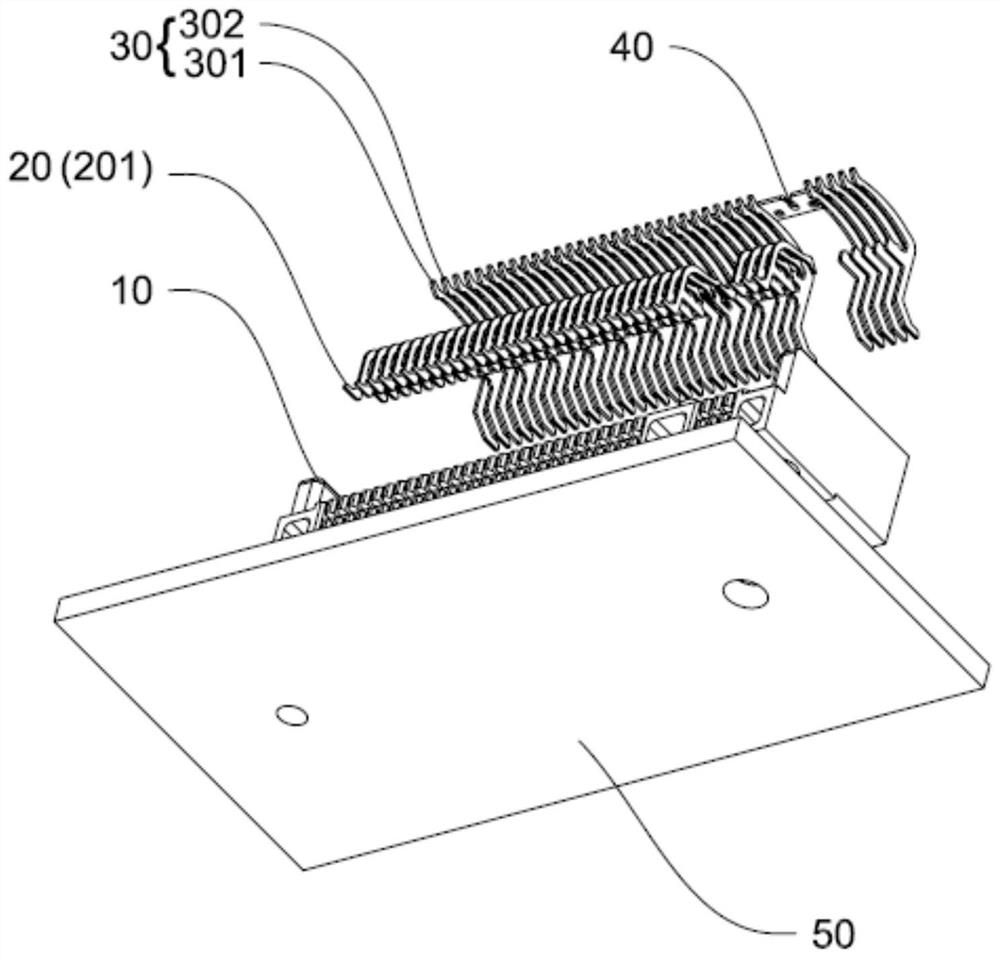

[0034] see figure 1 and figure 2 , the connector 1 includes an insulating body 10, a second terminal row 20, a first terminal row 30, a metal connecting piece 40 and a circuit board 50, the second terminal row 20 is arranged on the insulating body 10, and the second terminal row 20 partially extends The outside of the insulating body 10 is connected to the circuit board 50 , and the second terminal row 20 is used for conducting electricity. The first terminal block 30 is arranged on the insulating body 10, and part of the first terminal block 30 extends out of the insulating body 10 to be connected to the circuit board 50. The first terminal block 30 is used for grounding and transmitting high-speed signals. One end of the first terminal block 30 is connected to the circuit board 50. One end of the second terminal row 20 is disposed opposite to each other. The metal connecting piece 40 is arranged on the insulating body 10 , and some of the terminals in the first terminal r...

Embodiment 2

[0043] The difference between the second embodiment and the first embodiment is that the structures of the insulating body 10' and the ground terminal 301' are different. Specifically,

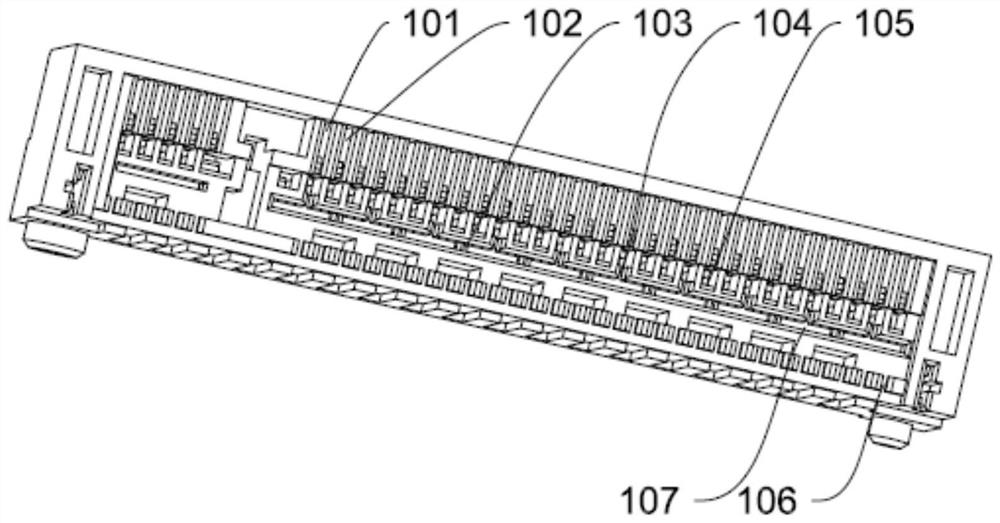

[0044] see Figure 11 and Figure 12 , the insulating body 10' is not provided with the first mounting groove 107 and the first fixing column 103 in the first embodiment, but the insulating body 10' is provided with several second fixing columns 115' and second mounting grooves 116'. The insulating body 10' is provided with a first receiving cavity 108', a plurality of first through holes 101', a plurality of second through holes 102', a plurality of first fixing grooves 104', a plurality of second fixing grooves 105', and a plurality of third fixing grooves 106', a plurality of fourth fixing grooves 109', a plurality of fifth fixing grooves 112', a plurality of sixth fixing grooves 113' and a plurality of seventh fixing grooves 114'. A through hole 101' and a second through hole 102' are di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com