Turbine flowmeter flow compensation parameter test system

A turbine flowmeter and flow compensation technology, applied in the field of precision instruments, can solve problems such as changes and difficulty in effectively maintaining the balance state of the impeller

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] This embodiment provides a magnetic levitation-based tangential turbine flowmeter, which has the same main structure and working principle as a conventional tangential turbine flowmeter; both include a meter head and a measurement component.

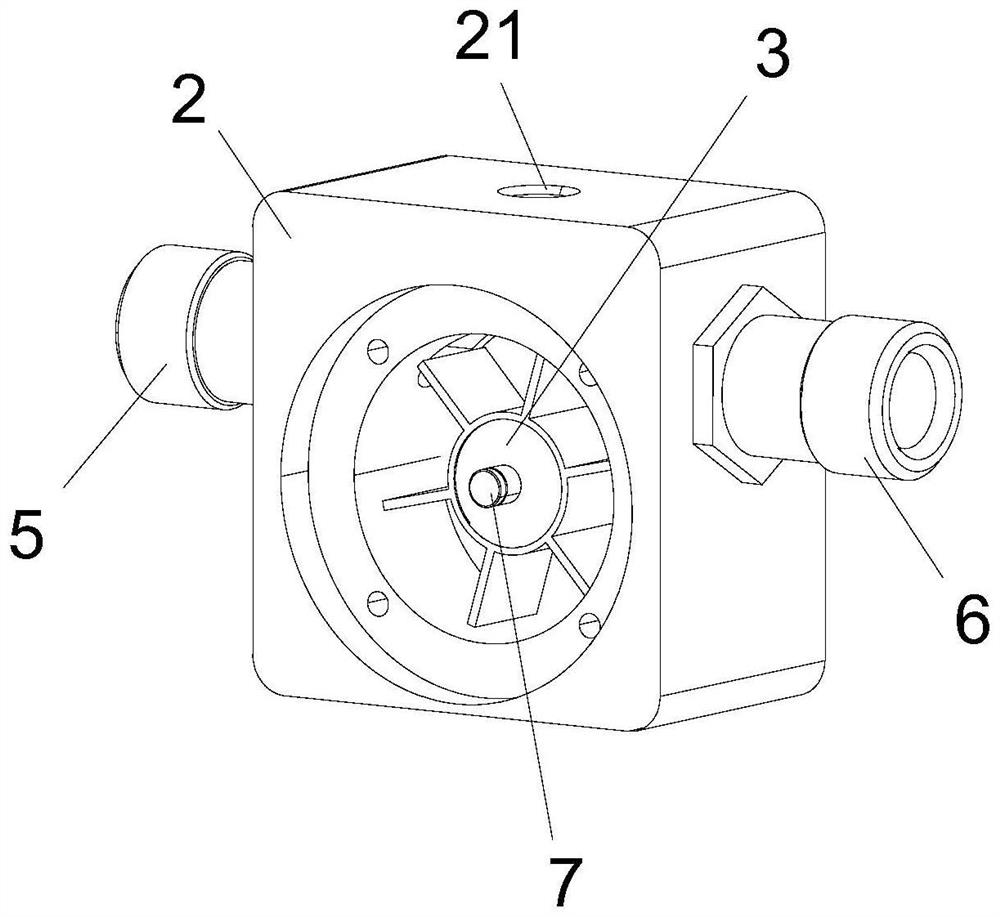

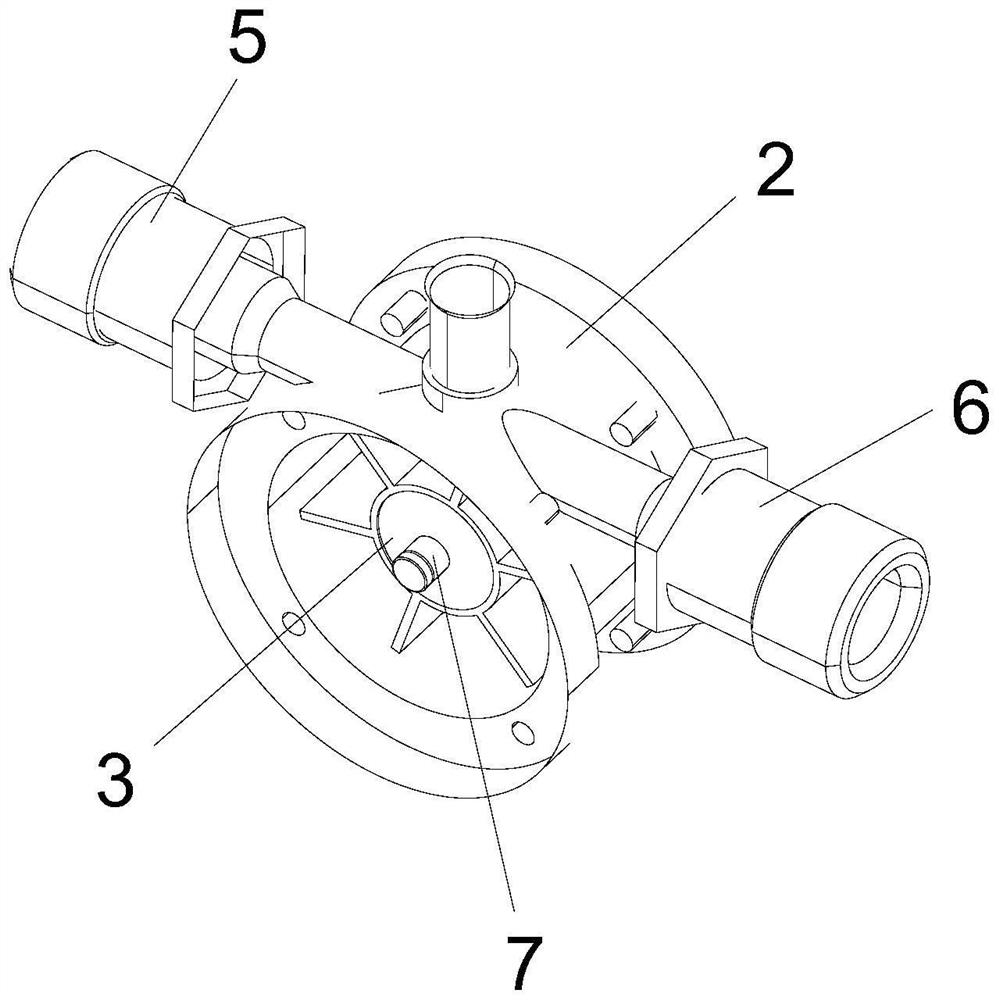

[0045] Among them, such as figure 1 and figure 2 As shown, the measurement assembly includes a base plate 1 , a turbine casing 2 , an impeller 3 , two bushings 4 , a fluid inlet 5 and a fluid outlet 6 . The turbine casing 2 is fixedly connected to the base plate 1 , and the two shaft sleeves 4 are respectively connected to both sides of the turbine casing 2 . Both ends of the impeller shaft 7 in the impeller 3 pass through the turbine casing 2 and are rotatably connected with the two shaft sleeves 4 . The turbine shell 2 contains a turbine cavity, the impeller 3 is located in the turbine cavity, the fluid inlet 5 and the fluid outlet 6 are respectively located on both sides of the turbine cavity, and the connecting direction of...

Embodiment 2

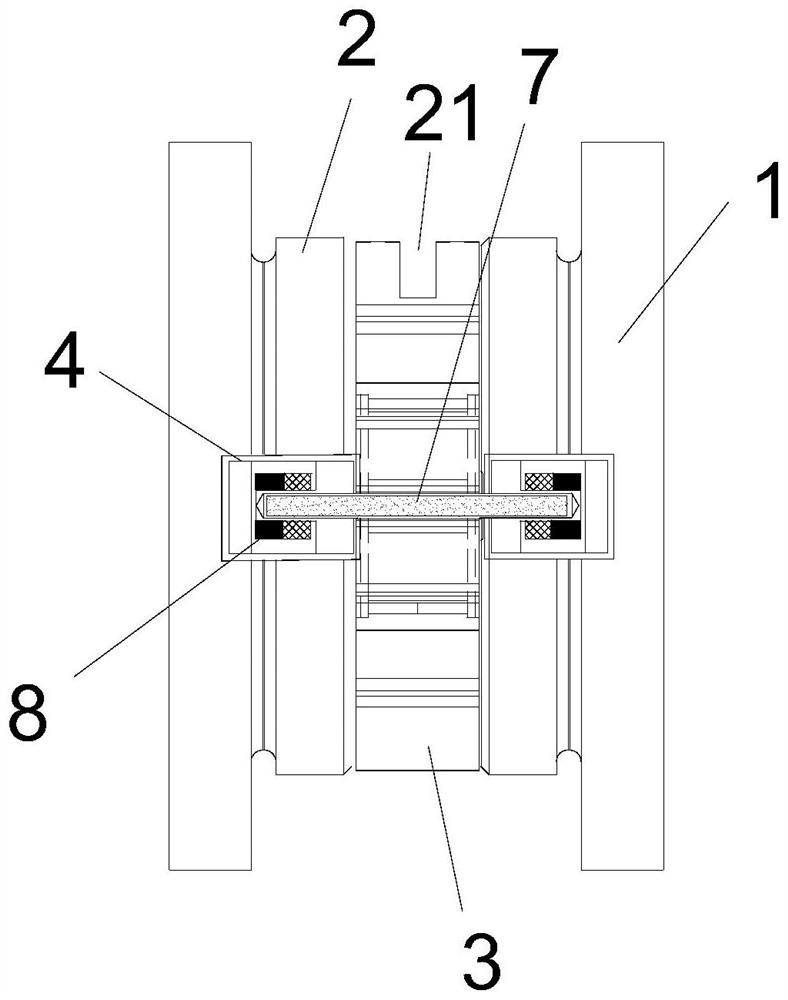

[0070] This embodiment provides a method for testing the deviation correction of the impeller 3 of a turbine flowmeter, and the flowmeter tested by the test method is the tangential turbine flowmeter based on the side suspension in the first embodiment. In the turbine flowmeter, magnetic bearings 8 are arranged in the shaft sleeves 4 at both ends of the impeller 3 ; each set of magnetic bearings 8 includes a permanent magnet group 81 and an electromagnet group 82 . The permanent magnet group 81 and the electromagnet group 82 in the magnetic bearing 8 balance the influence of the gravity of the turbine and the dynamic load caused by the fluid by generating a constant magnetic field and a dynamic magnetic field respectively, thereby keeping the impeller shaft 7 always in the center of the shaft sleeve 4 .

[0071] The main task of the testing method provided in this embodiment is to establish a mapping relationship between the excitation current of the electromagnet group 82 in t...

Embodiment 3

[0101] This embodiment provides a test system for flow compensation parameters of a turbine flowmeter, and the test system is mainly used to implement the deviation correction test method of the impeller 3 of a turbine flowmeter as described in the second embodiment.

[0102] The test object of the test system provided in this embodiment is the magnetic levitation-based tangential turbine flowmeter as described in Embodiment 1. like Figure 1-3 As shown, the turbine flowmeter includes two parts: the meter head and the measuring assembly. The measurement assembly includes: a base plate 1 , a turbine casing 2 , an impeller 3 , two shaft sleeves 4 , a fluid inlet 5 and a fluid outlet 6 . Both sides of the turbine casing 2 are fixedly connected to the base plate 1 , and the shaft sleeve 4 is fixedly connected to the turbine casing 2 . The two ends of the impeller shaft 7 in the impeller 3 are respectively sleeved in the two shaft sleeves 4, and the impeller shaft 7 and the shaft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com