Automatic electronic testing fixture for battery case of new energy automobile

A technology for new energy vehicles and battery cases, which is applied to instruments, measuring devices, mechanical measuring devices, etc., can solve the problem of lack of batch testing methods and devices for electronic inspection tools, and achieve the effect of improving the efficiency of testing and testing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

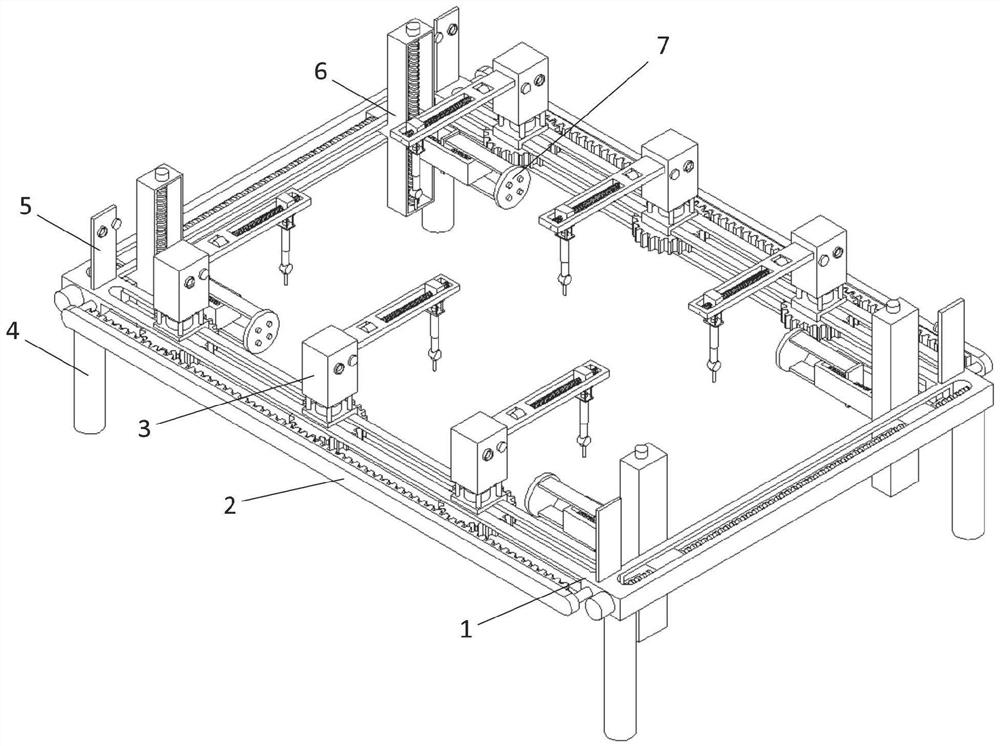

[0063] An automatic electronic inspection tool for battery shells of new energy vehicles, such as Figure 1-4 shown, including:

[0064] paper box 1;

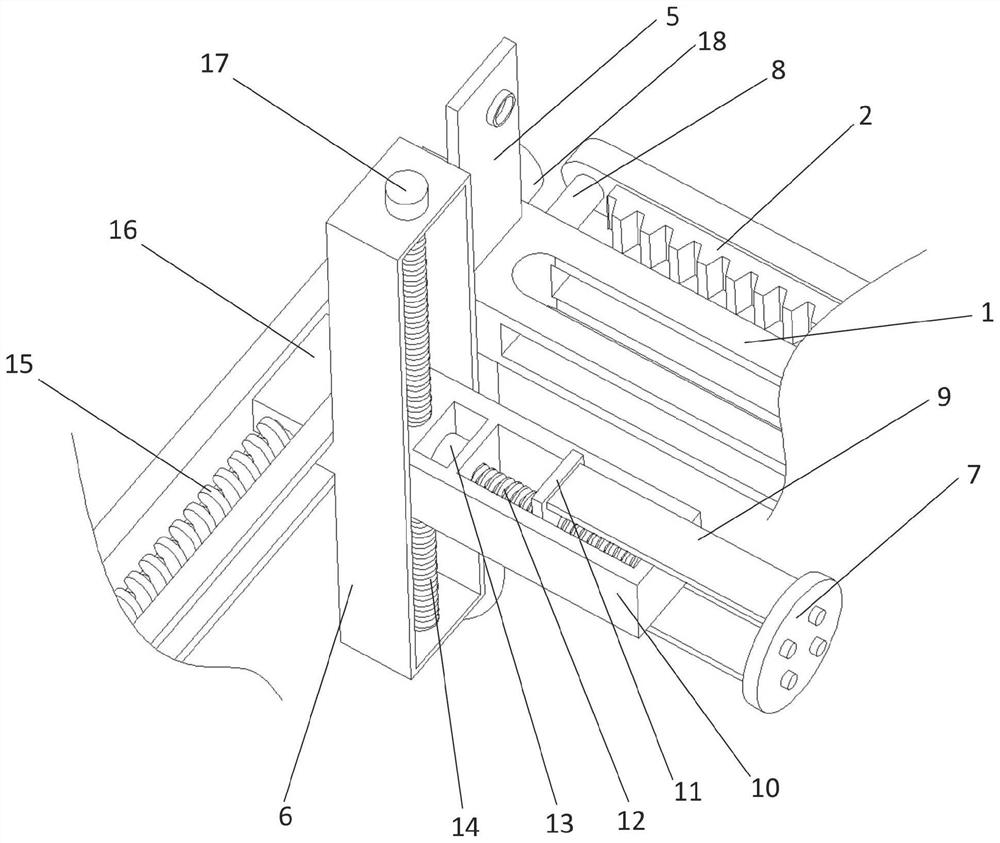

[0065] The two groups of clamping units are symmetrically arranged on the frame edges of the two ends of the return frame 1 respectively, and are used for clamping the battery case. like figure 2 and 4 As shown, each group of clamping units includes: a linear drive mechanism, which is arranged at the end of the return frame 1; two groups of clamping mechanisms; The driving mechanism drives the two moving blocks 16 to move relative or opposite; the vertical driving unit is connected with one moving block 16; the lateral driving unit is erected on the vertical driving unit, and is driven to move up and down by the vertical driving unit; the clamping plate 7. It is erected in front of the lateral drive unit, and is driven to move forward and backward by the lateral drive unit. Among them, the linear drive mechanism synchrono...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com