Method for realizing flight control of A-wing aircraft

A flight control and A-wing aircraft technology, applied in the aviation field, can solve the problems of conflicting vertical take-off and landing modes, low flight efficiency, poor safety, etc., to improve the vertical take-off and landing capability, compress the vertical take-off and landing time, and reduce the side area. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

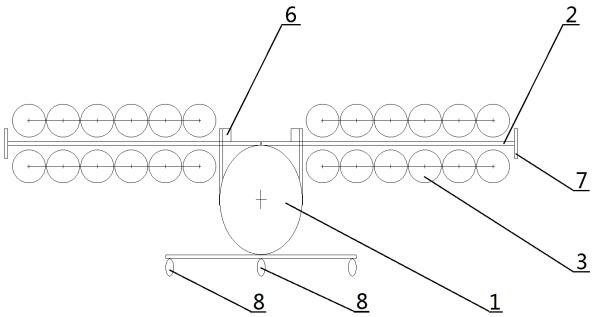

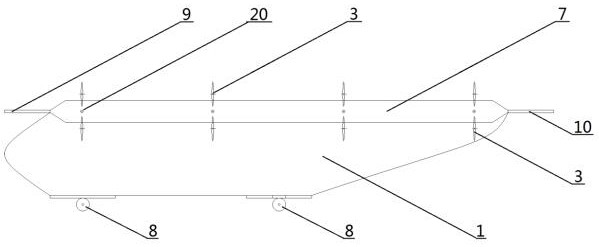

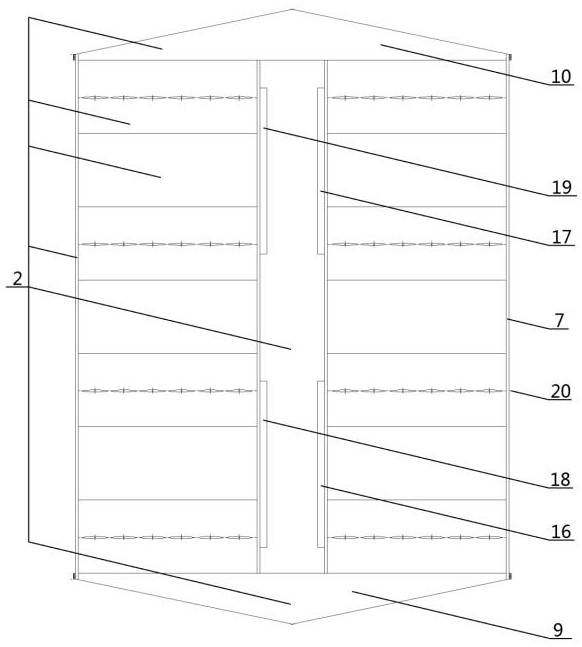

[0053] Example 1: as Figure 1-20 As shown in the figure, the method for realizing the flight control of the wing aircraft, the wing aircraft has a large-area shell-shaped wide-chord wing, the upper and lower parts of the shell-shaped wing are respectively fixed with drive devices, and the drive devices are arranged in two rows along the chord direction of the wing. , Densely distributed along the span of the wing, the thickness of the driving device to generate a layered driving airflow on the surface of the wing is less than 0.2 times the chord length of the large-area shell-shaped wide-chord wing; the large-area shell-shaped wide-chord wing is designed as a combined type , it is divided into 4 sections of tilting wing and 5 sections of fixed wing. The many driving devices are divided into four sections, the left front section and the right front section, with the aerodynamic center of the large-area shell-shaped wide-chord wing as the origin. The partitions include 2 sectio...

Embodiment 2

[0063] Example 2: as Figure 1-22 As shown in the figure, the method for realizing the flight control of an A-wing aircraft, the single-seat sports A-wing aircraft has a large-area shell-shaped wide-chord wing, and the upper and lower parts of the shell-shaped wing are respectively fixed and installed with driving devices; The aerodynamic center of the large-area shell-shaped wide-chord wing is used as the origin to divide the wing and the driving device into four sections. Wings, front left and right front divisions both include 1 section of tilting wing and 2 sections of fixed wing, and left rear section and right rear section both include 1 section of tilting wing and 1 section of fixed wing. The aspect ratio of the single-seat sports A-wing aircraft is λ=l / b=2, and the chord length of the tilting wing is 1.5 meters. A row of propellers with a diameter of 0.7 meters is arranged on the upper and lower parts of each tilting wing, and the number of propellers in each row is 6...

Embodiment 3

[0064] Example 3: as Figure 1-20 As shown in , 23-24, this method for realizing the flight control of the wing aircraft, the 3-seat family wing aircraft has a large-area shell-shaped wide-chord wing, and the upper and lower parts of the shell-shaped wing are respectively fixed with driving devices; The driving device takes the aerodynamic center of the large-area shell-shaped wide-chord wing as the origin to divide the wing and the driving device into four sections, and the large-area shell-shaped wide-chord wing is designed as a combined type, which is divided into 6 sections of tilting wings laterally. and 3-section fixed wing, the left front section and right front section both include 3-section tilting wing and 2-section fixed wing, and the left rear section and right rear section both include 3-section tilting wing and 1-section fixed wing. The aspect ratio of the 3-seat family A-wing aircraft is λ=l / b=0.7, and the chord length of the tilting wing is 1.5 meters. A row o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com