Magnetic adsorption cavity type solar particle heat absorber

A magnetic adsorption, solar energy technology, applied in the field of cavity solar particle heat absorbers, can solve the problems of uncontrollable particle flow trajectory, easy occurrence of hot spots, short heat absorption time, etc., to improve light-to-heat conversion efficiency and safe and reliable operation. The effect of improving the light-heat conversion efficiency and improving the thickness uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0026] The present invention will be further described below in conjunction with the accompanying drawings.

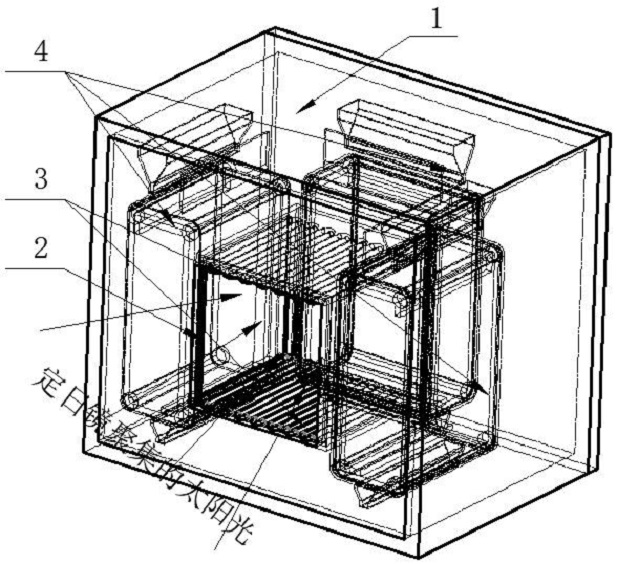

[0027] like Figure 1-Figure 3As shown, the present invention includes solid particles 15 that are resistant to high temperature and can be magnetically attracted by magnetic force, a cavity frame 2 that is a rectangular cavity with openings on four sides except the upper and lower sides, and three sets of particle transporters. Transportation device 4, a thermal insulation cover 1 with a cavity and an opening on one side for heat insulation; the particle transportation device 4 includes a belt conveyor 8 with a magnetic field penetrable and high temperature-resistant conveyor belt 801 , the conveyor belt 801 in the conveyor 8 at least includes a horizontal section and a vertical section, a particle distributor 5 that holds the solid particles 15 and evenly distributes the particles to the horizontal section of the conveyor belt 801, and controls the lower end of the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com