Flocculant screening equipment and screening method

A technology for screening equipment and flocculants, applied in chemical instruments and methods, multi-stage water/sewage treatment, water/sludge/sewage treatment, etc., can solve the risk of stable operation of sewage treatment plants and increase the operating pressure of subsequent treatment units and other issues, to achieve the effect of reducing potential adverse effects, reasonable design, accurate and comprehensive comprehensive evaluation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

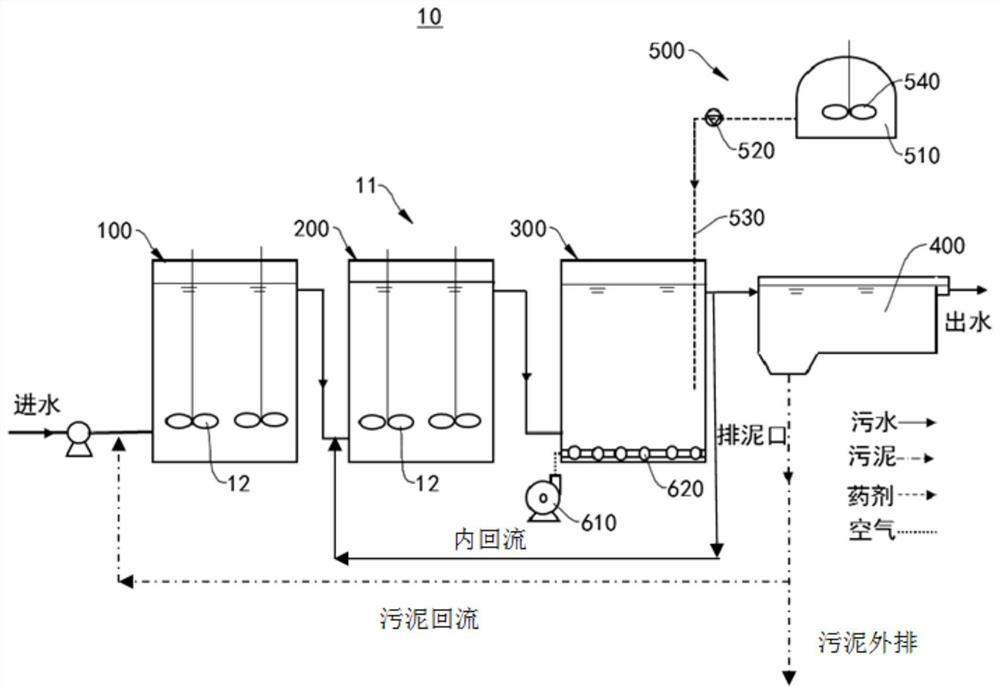

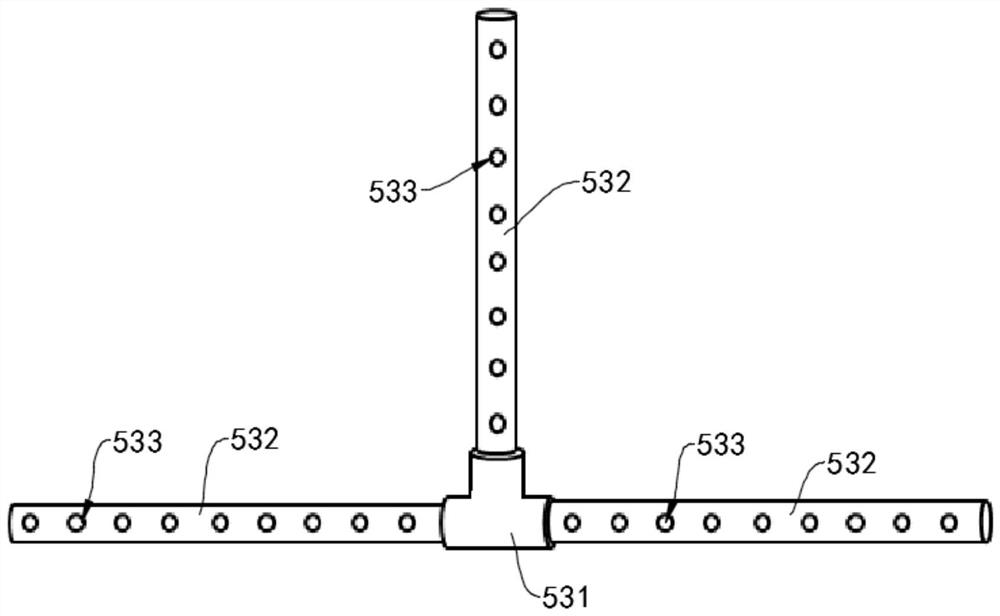

[0061] Please refer to figure 1 , figure 1 It is a schematic structural diagram of a flocculant screening device 10 provided in an embodiment of the present invention. from figure 1 A flocculant screening device 10 can be seen in the figure, which includes a biochemical treatment component 11, a secondary sedimentation tank unit 400, a dosing unit 500, and an aerator.

[0062] The biochemical treatment assembly 11 includes at least one reactor, and the reactor is the anaerobic unit 100, the anoxic unit 200 or the aerobic unit 300; when the biochemical treatment assembly 11 includes multiple reactors, the multiple reactors are connected in series;

[0063] The outlet of the biochemical treatment assembly 11 is connected to the inlet of the secondary sedimentation tank unit 400, and the sludge discharge port of the secondary sedimentation tank unit 400 is optionally connected to the inlet of the biochemical treatment assembly 11;

[0064] The aerator is connected to the aerob...

Embodiment 2

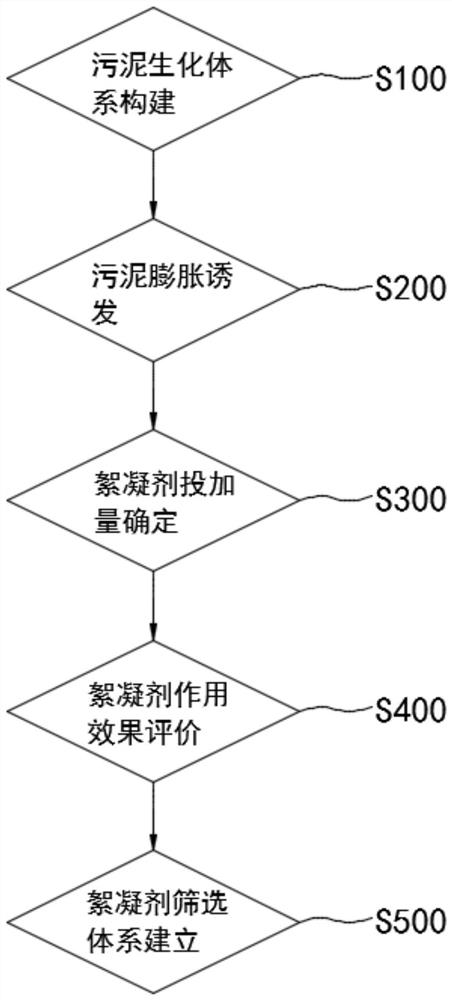

[0092] Please refer to image 3 and Figure 4 , another object of the present invention includes providing a screening method including the above, which can form the phenomenon of sludge bulking caused by different incentives through the regulation of different key parameters, which can be used to evaluate and analyze the use effect of flocculants, and can scientifically and effectively The flocculant is screened to give full play to the role of the flocculant and reduce the cost of use.

[0093] A screening method, the screening method is based on the flocculant screening device 10 of any one of the above embodiments, and the method comprises the following steps:

[0094] S100: Sludge biochemical system construction: The equipment used to screen flocculants and optimize the dosing method is a spliced reactor based on the activated sludge treatment process, with organic load, nutrient ratio, aeration intensity, and pH as the main control parameters , simulating the actual ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com