Sharp-bottomed paper bag forming machine

A technology of forming machine and forming mechanism, applied in papermaking, bag making, paper/cardboard containers, etc., can solve the problems of unfavorable bottom forming and collection of paper bags, affecting production efficiency, etc. Reliable attachment to ensure the effect of the absorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

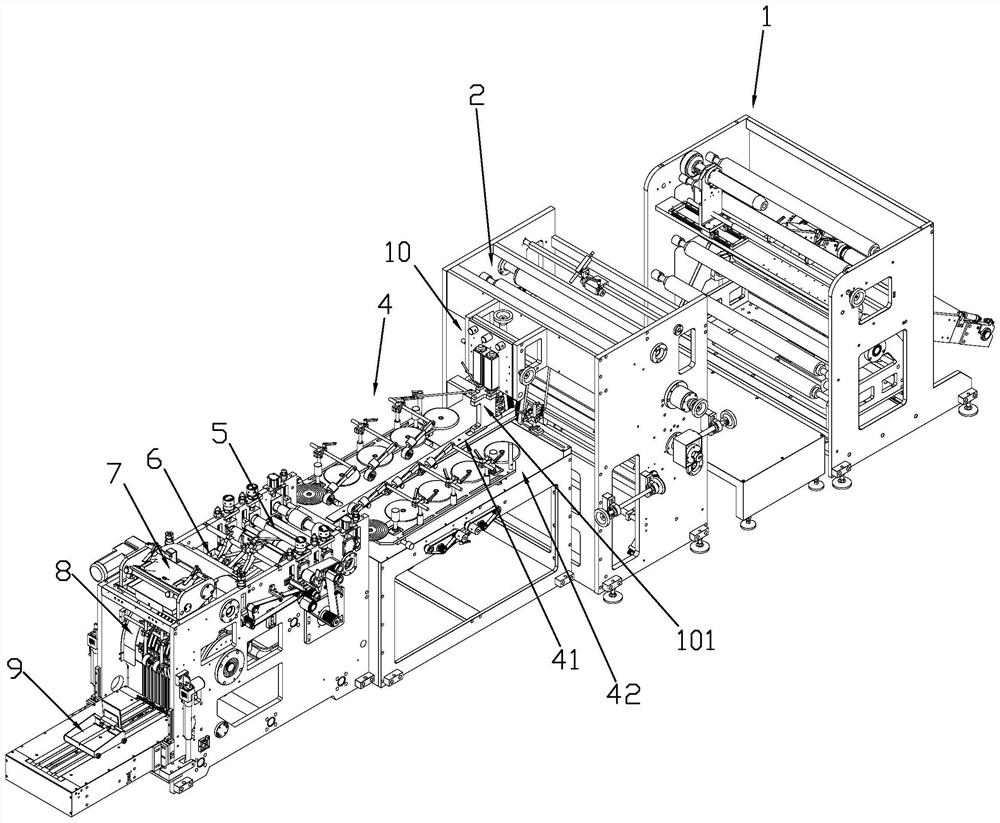

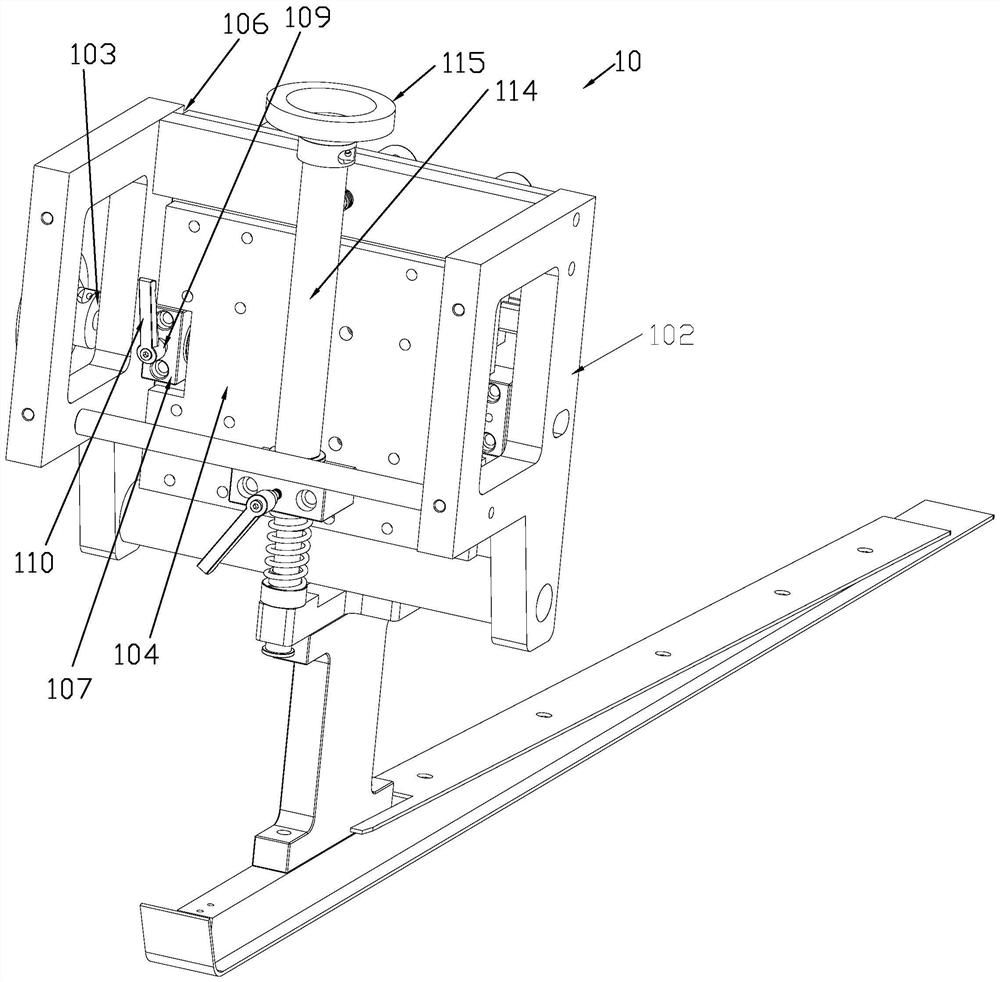

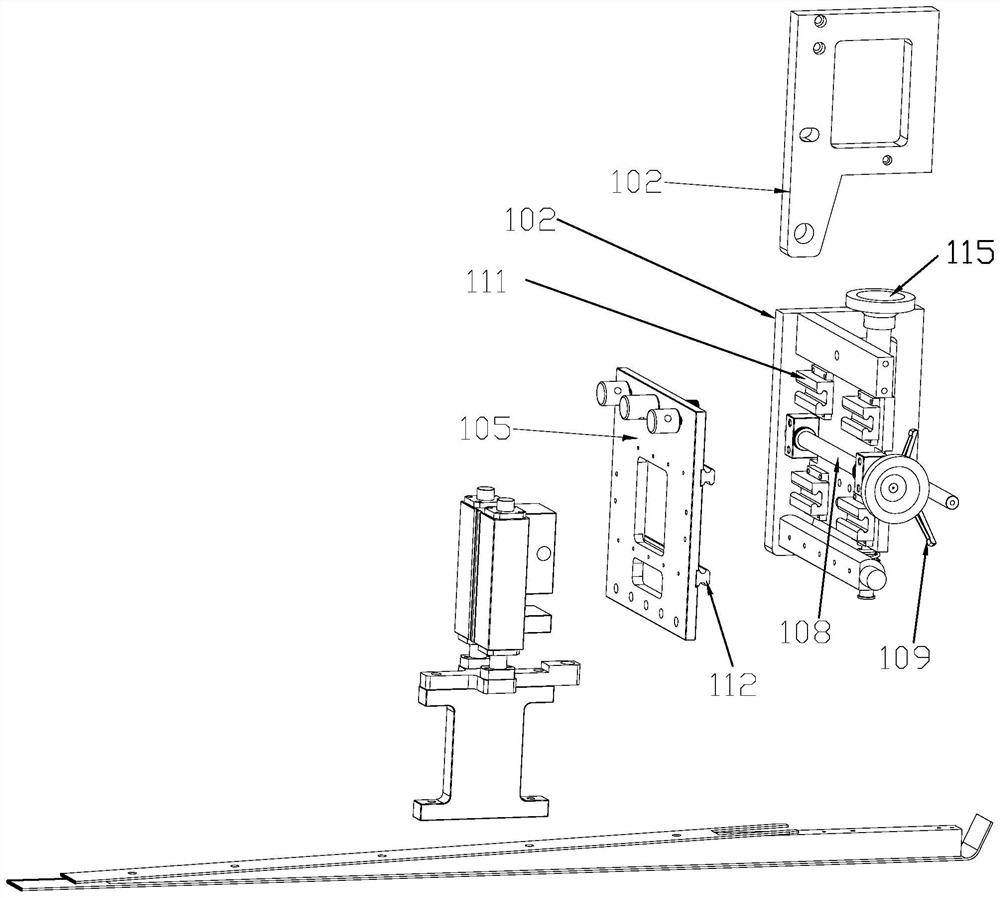

[0036] see Figure 1-Figure 11 Shown: a pointed bottom paper bag forming machine, including a feeding mechanism 1, a puncturing mechanism 2, an edge gluing mechanism, a forming mechanism 4, a breaking mechanism 5, a conveying mechanism 6, a primer coating mechanism 7, and a bottom folding mechanism. The mechanism 8 and the receiving mechanism 9, the forming adjusting mechanism 10 is provided between the forming mechanism 1 and the piercing mechanism 2, and the forming adjusting mechanism 10 includes an origami board mounting seat 101 connected to the top of the origami board 41 of the forming mechanism 4. The folding board is installed The seat 101 is erected on the piercing mechanism 2 through the oppositely established fixing seat 102. One side of the fixing seat 102 is provided with a left and right adjusting hand wheel 103, and a left and right adjusting hand wheel 103 is arranged between the fixing seat 102 and the folding board mounting seat 101. A left and right adjustm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com