Expansion sleeve type turning and grinding mandrel clamp

A technology of expanding sleeves and turning and grinding, which is applied in the direction of expanding the mandrel and grinding the workpiece support, which can solve the problems of complex positioning, connection and adjustment of the fixture and the processing machine tool, reduce the overall precision of the parts, and the small application range of the device. Good processing effect, improved precision and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

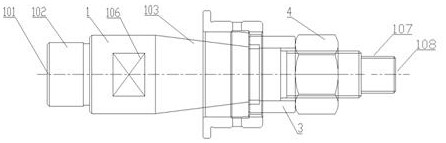

[0053] When in use, the first 102 end of the cylindrical section of the spindle body 1 is directly clamped and positioned on the lathe by a three-jaw chuck, and the second end of the cylindrical section 107 at the other end of the B-type center hole 2 108 is positioned with the rear center of the tailstock. The spring expansion sleeve 2 is installed on the outer side of the taper section 103 of the spindle body 1. The inner hole of the machined part is a smooth hole as the benchmark, and the optical outer circular spring expansion sleeve is selected. The machined part is placed at the spring expansion sleeve 2. The taper is the same as the taper of the taper section 103 of the spindle body 1, and the taper of the taper section 103 and the spring expansion sleeve 2 are both 7:24; one side of the taper section 103 is the guide section 104, the outer side of the guide section 104 The clamping guide sleeve 3 is sleeved, the side of the guide section 104 away from the tapered sectio...

Embodiment 2

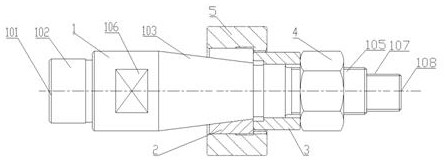

[0055] When in use, the workpiece 5 is installed at the spring expansion sleeve 2, the inner hole of the machined part has internal teeth, and when the small diameter 501 of the workpiece 5 with inner teeth is processed as the benchmark, the spring expansion with a smooth outer circle is selected. Then place the B-type center hole 101 at the cylindrical section 1 102 directly on the lathe with the spindle hole center, and the B-type center hole 2 108 at the cylindrical section 2 107 directly on the lathe with the rear center of the tailstock. , the spring expansion sleeve 2 is installed on the outside of the taper section 103 of the spindle body 1, the inner taper of the spring expansion sleeve 2 is the same as the taper of the taper section 103 of the spindle body 1, and the taper of the taper section 103 and the spring expansion sleeve 2 are the same is 7:24; one side of the tapered section 103 is the guide section 104, the outer side of the guide section 104 is sleeved with ...

Embodiment 3

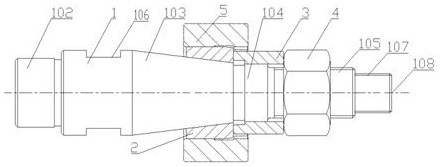

[0057] When in use, the cylindrical section 1 102 is directly clamped and positioned on the lathe with a three-jaw chuck, and the cylindrical section 2 107 is also directly clamped and positioned on the lathe with a three-jaw chuck, and the spring sleeve 2 is installed on the lathe body 1. On the outside of the taper section 103, the inner hole of the machined part is with internal teeth, and the machined part is installed at the spring expansion sleeve 2. When the key side 503 of the machined piece 5 with teeth in the machining inner hole is used as the benchmark, the outer tooth is selected. The round spring expansion sleeve is processed. The inner taper of the spring expansion sleeve 2 is the same as the taper of the taper section 103 of the spindle body 1. The taper of the taper section 103 and the spring expansion sleeve 2 are both 7:24; The side is a guide section 104, the outer side of the guide section 104 is sleeved with the clamping guide sleeve 3, the side of the gui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com