Method for processing dry-type ripened beef tenderloin by using three-bacterium compound fermentation inoculant

A beef tenderloin and compound fermentation technology, applied in food science and other directions, can solve problems such as affecting the growth, reproduction and metabolism of fermented inoculants, unable to fully apply the aging process, and have not yet developed fermentation inoculants, etc., to achieve a soft and tender taste. Juice, Flavor Enhancement, Unique Flavor Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

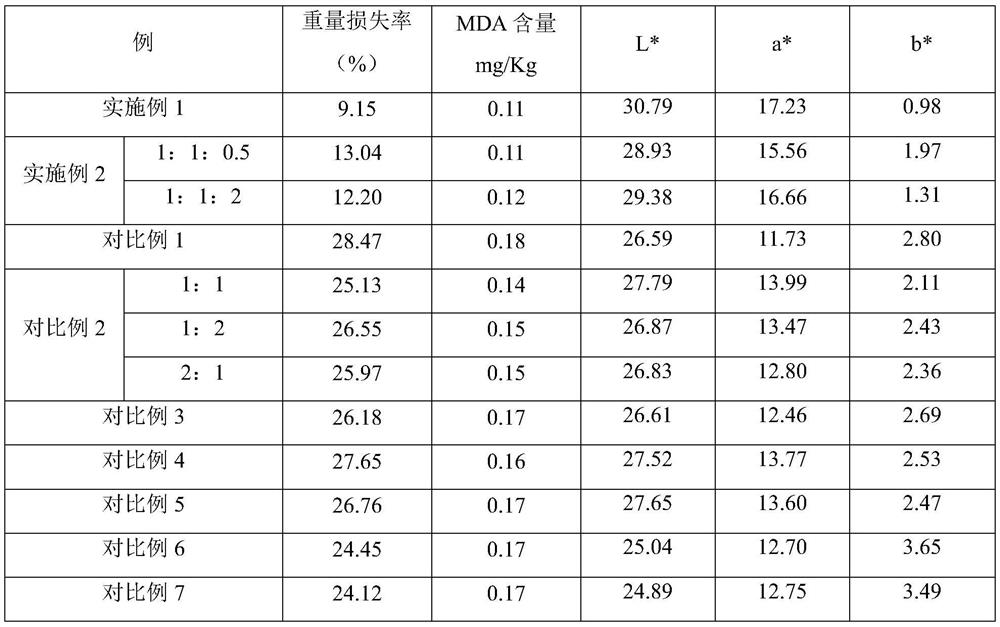

[0039] A dry-aged beef tenderloin processing method using three-bacteria compound fermentation inoculants, comprising the following steps:

[0040] (1) Preparation of mixed bacterial suspension:

[0041] Add 5 ml of sterile saline to the cultured Debaryomyces hansenii and Pediococcus pentosaceus slanted tubes, scrape off the bacteria with a disposable inoculating ring, mix well, and count the viable bacteria in the bacterial solution by the plate count method. Count, use a pipette to absorb the bacterial solution of Debaryomyces hansenii and Pediococcus pentosaceus into 200 mL of sterile physiological saline, and then add 1 g of the purchased commercial Staphylococcus carnivora, mix well, and make the final bacterial suspension in the The number of viable bacteria of each bacteria reaches 10 6 cfu / mL, that is, the viable count of Staphylococcus meatus, Debaryomyces hansenii and Pediococcus pentosaceus is 1:1:1 to obtain a mixed bacterial suspension;

[0042] (2) Dry-aged bee...

Embodiment 2

[0045] Adjust the ratio of the viable counts of Staphylococcus meatus, Debaryomyces hansenii and Pediococcus pentosaceus in the mixed bacterial suspension of step (1) of Example 1 to 1:1:0.5, 1:1:2, other and Example 1 was kept the same, and dry-aged beef tenderloin was obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com