Beam body hoisting device convenient to operate

It is a technology with convenient operation and hoisting device, which is applied in the direction of transportation and packaging, load hanging components, etc. It can solve the problems of potential safety hazards, serious shaking of steel box girders, and inability to ensure precise positioning of steel box girders, so as to ensure high quality, The effect of precise positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

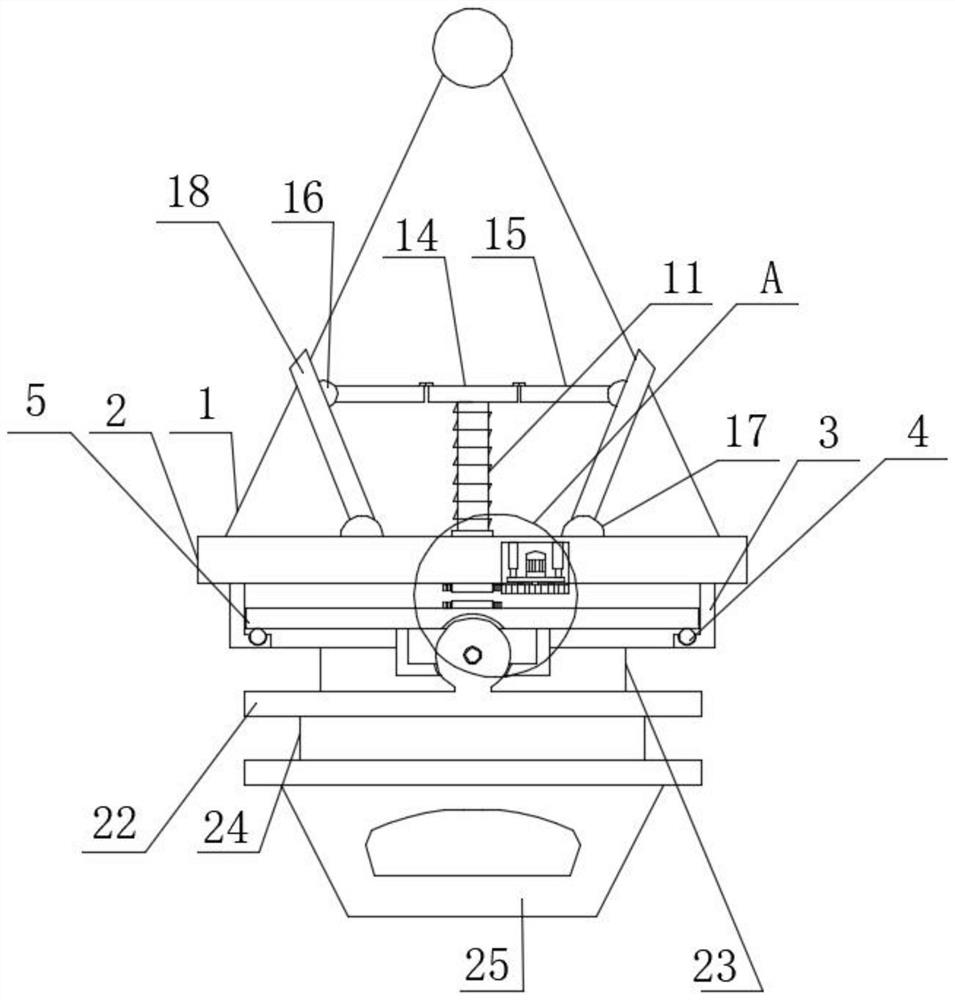

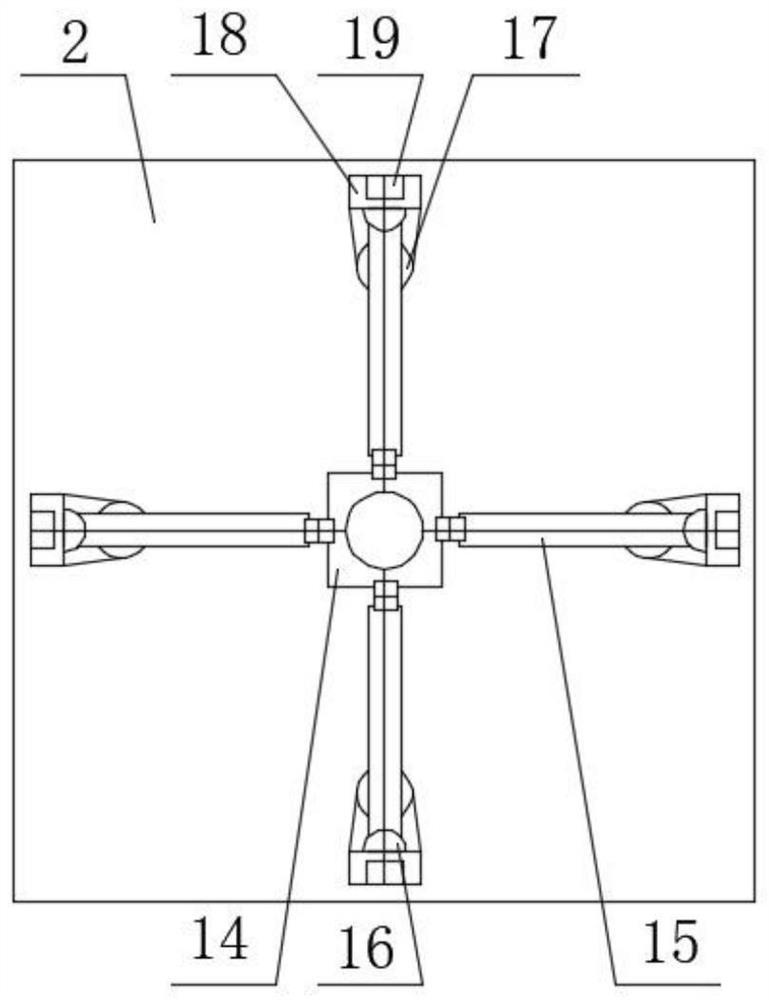

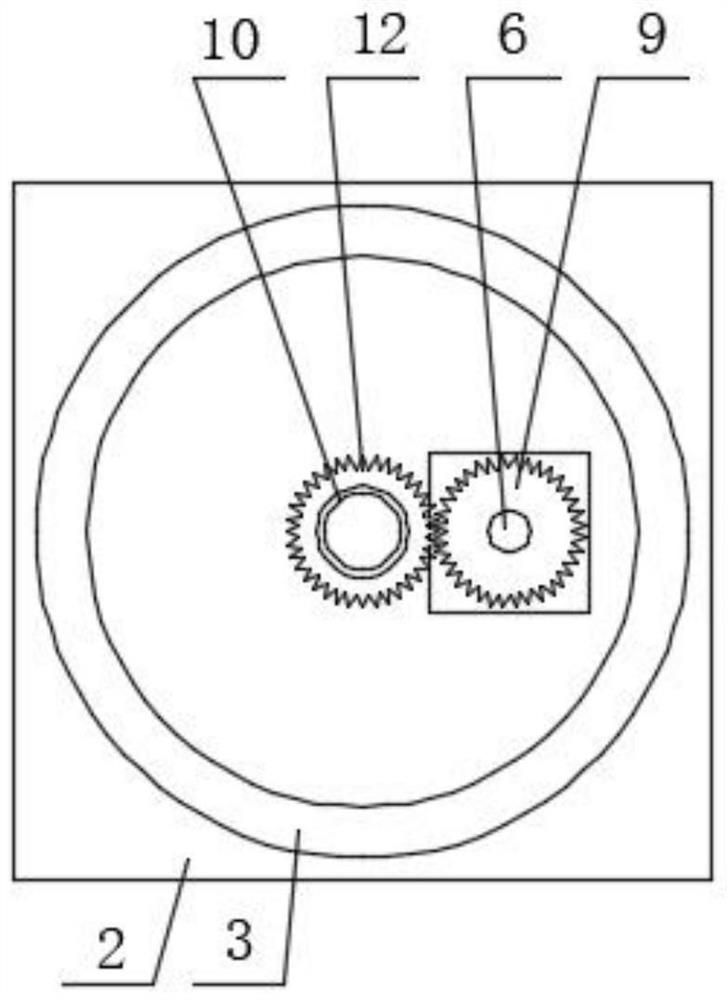

[0022] see Figure 1-5 , The present invention provides a technical solution: a beam body hoisting device with convenient operation, including steel wire rope 1, upper beam body 2 and steel box beam 25, characterized in that: the upper beam body 2 is equipped with a damping mechanism, and the damping mechanism is installed on the upper beam body 2. The mechanism is used for shock absorption when the wire rope 1 shakes violently during the hoisting process. The lower beam body 22 is installed at the lower end of the upper beam body 2. The upper beam body 2 and the lower beam body 22 are arranged in parallel, and the lower beam body 22 can be opposite to the upper beam body 2. To adjust the plane rotation angle and the vertical plane rotation angle, the upper beam body 2 is provided with an adjustment drive mechanism, and the adjustment drive mechanism can choose to adjust the use of the damping mechanism or the adjustment of the plane rotation angle of the lower beam body 22, th...

Embodiment 2

[0031] see Figure 1-5 , The present invention provides a technical solution: a beam body hoisting device with convenient operation, including steel wire rope 1, upper beam body 2 and steel box beam 25, characterized in that: the upper beam body 2 is equipped with a damping mechanism, and the damping mechanism is installed on the upper beam body 2. The mechanism is used for shock absorption when the wire rope 1 shakes violently during the hoisting process. The lower beam body 22 is installed at the lower end of the upper beam body 2. The upper beam body 2 and the lower beam body 22 are arranged in parallel, and the lower beam body 22 can be opposite to the upper beam body 2. To adjust the plane rotation angle and the vertical plane rotation angle, the upper beam body 2 is provided with an adjustment drive mechanism, and the adjustment drive mechanism can choose to adjust the use of the damping mechanism or the adjustment of the plane rotation angle of the lower beam body 22, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com