Method for calculating compression ratio of shaft sealing ring

A calculation method and sealing ring technology, which are applied in the direction of engine sealing, complex mathematical operations, mechanical equipment, etc., can solve the problems of affecting the compression amount of the sealing ring, affecting the groove depth, affecting the sealing performance of the product, etc., so as to reduce the oil leakage rate. , minimum compression rate accurate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

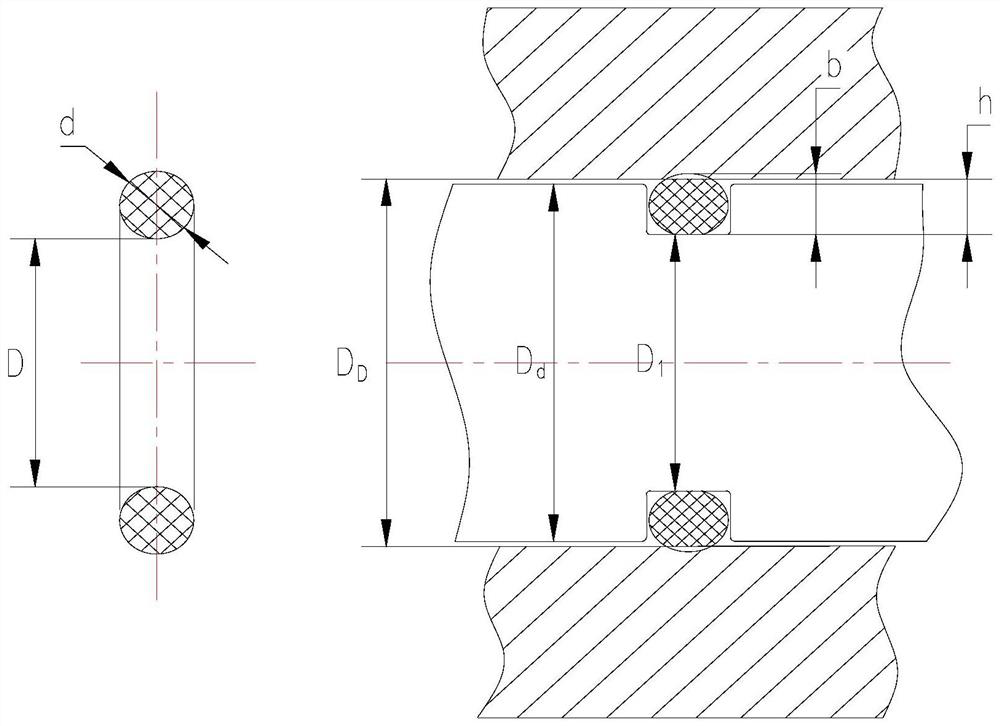

[0034] A shaft groove sealing structure such as figure 2 , the known sealing ring section diameter d=φ2.1±0.08, the nominal inner diameter of the sealing ring Nominal inside diameter of the hole Nominal outer diameter of shaft Bottom diameter D of shaft groove 1 =φ8.2±0.07, the coaxiality e of the shaft groove centerline with respect to the shaft centerline=φ0.05.

[0035] Among them, the following steps involve parameters: D 1min , D 1max Indicates the minimum and maximum value of the bottom diameter of the shaft groove, d min , d max Indicates the minimum and maximum diameter of the sealing ring section, D min , D max Indicates the minimum and maximum inner diameter of the sealing ring, D Dmin , D Dmax is the minimum and maximum value of the inner diameter of the assembly hole, D dmin is the minimum value of the shaft outer diameter.

[0036] In this embodiment, the sealing ring is in the minimum compression state, and the calculation steps of the minimum com...

Embodiment 2

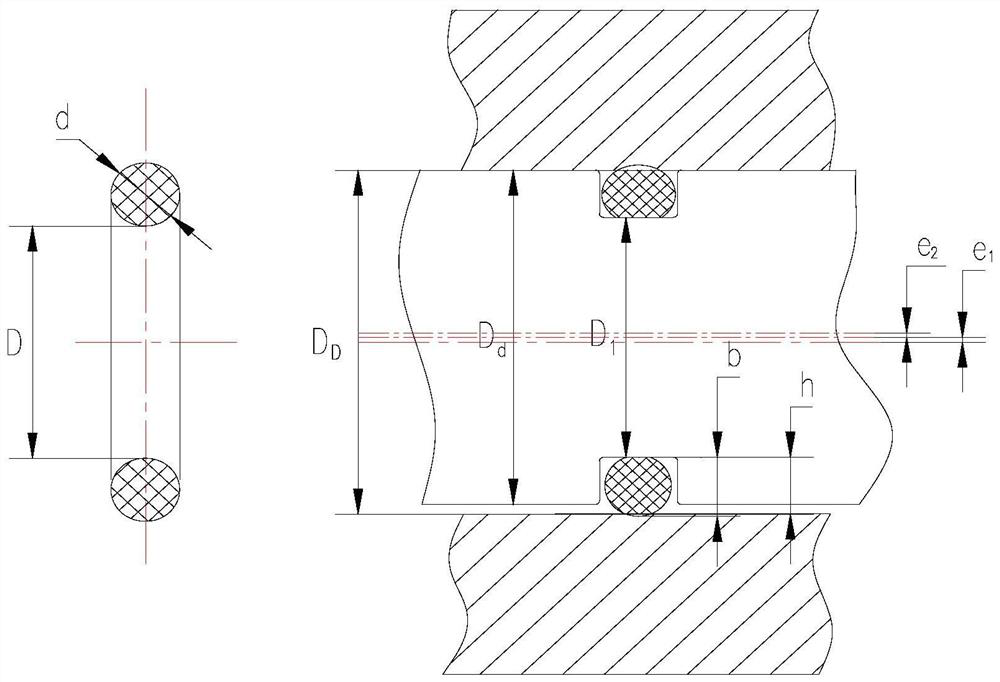

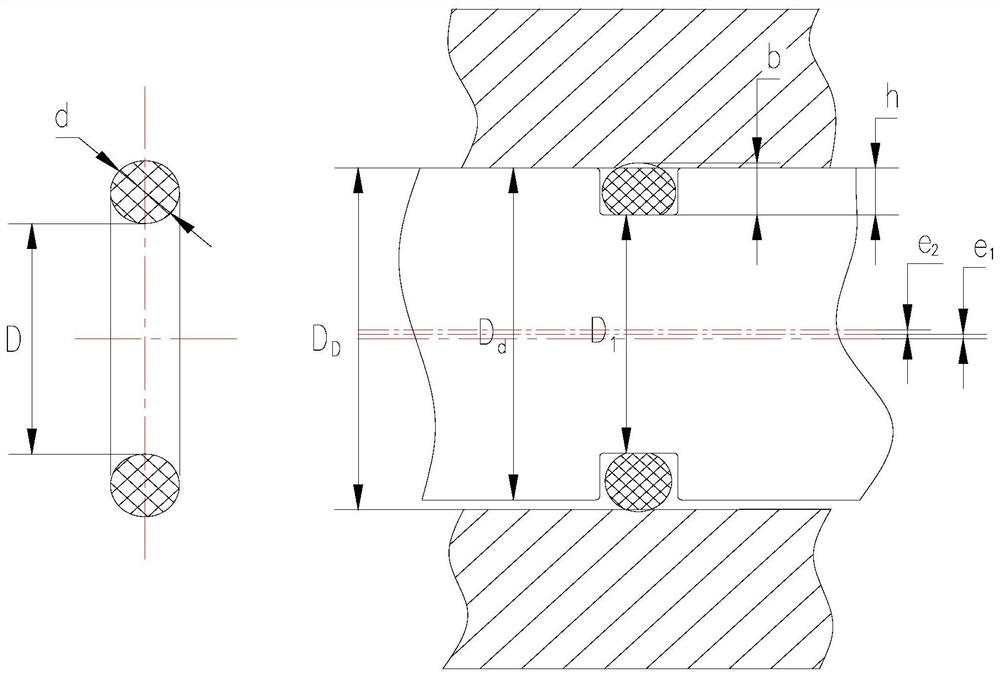

[0058] Embodiment 2, this embodiment is similar to Embodiment 1, except that the sealing ring is installed in the hole groove inside the casing, and the hole groove sealing structure is as follows: Figure 4 , Figure 5 As shown, the known sealing ring section diameter d=φ1.9±0.1, the nominal inner diameter of the sealing ring Nominal inside diameter of the hole Nominal outer diameter of shaft Bottom diameter of the hole The coaxiality e=φ0.08 of the hole and groove centerline relative to the hole centerline.

[0059] Among them, the following steps involve parameters: D dmin , D dmax are the minimum and maximum outside diameter of the seal shaft, d min , d max is the minimum and maximum diameter of the sealing ring section, D min , D max is the minimum and maximum value of the inner diameter of the sealing ring, D 2min , D 2max is the minimum and maximum value of the bottom diameter of the hole groove, D Dmax is the maximum value of the inner diameter of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com