Method for visually monitoring capsule leakage and oil conservator

A technology of oil conservator and capsule, which is applied in the direction of measuring the increase and decrease rate of fluid, using liquid/vacuum degree for liquid tightness measurement, transformer/inductor cooling, etc., which can solve high cost, unintuitive, transformer accidents, etc. problem, to achieve the effect of not easy to damage and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

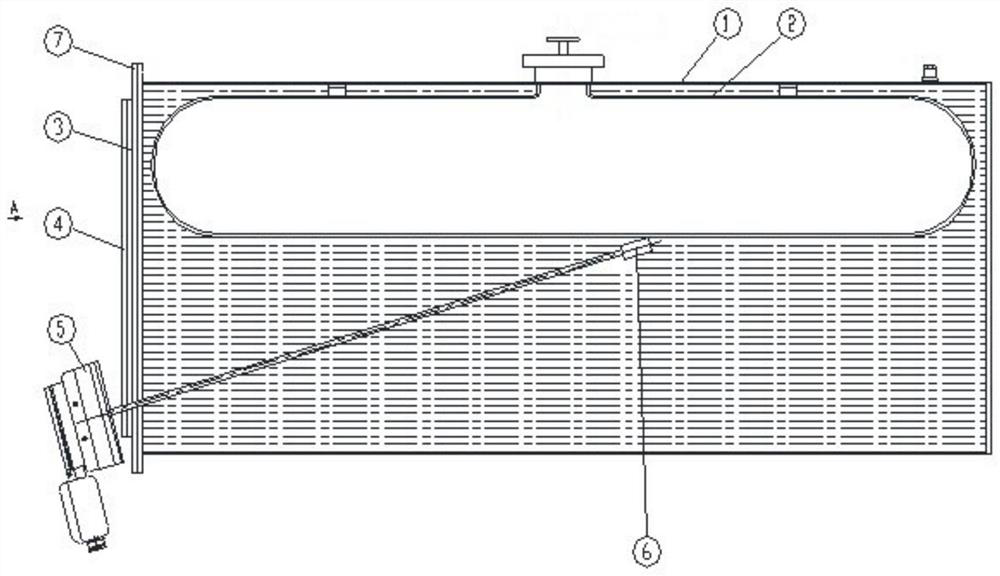

[0024] A first aspect of the present invention discloses a method for visually monitoring capsule leakage, specifically as follows figure 1 and figure 2 shown, including:

[0025] A hole is made on the oil conservator end cover 7 of the capsule oil conservator, the flange plate 3 is welded on the hole, and then the glass oil level gauge 4 is connected to the flange plate 3; When the capsule 2 is in normal operation, observe the transformer oil in the oil conservator from the glass oil level gauge 4 and fill the entire oil conservator. If the capsule 2 is damaged and leaks, observe the oil level in the oil conservator from the glass oil level gauge 4. Descend to the normal oil level in the oil conservator.

[0026] In some embodiments, if the capsule 2 is damaged and leaked, the capsule 2 will no longer float on the oil surface of the oil conservator, and the main oil level gauge float 6 will press down the damaged capsule 2 to a position below the normal oil level , causin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com