Wheel type dredging robot

A robot and wheeled technology, applied in the field of pipeline cleaning, can solve the problems of inability to turn or cross smoothly, single function, etc., and achieve good effect of dredging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

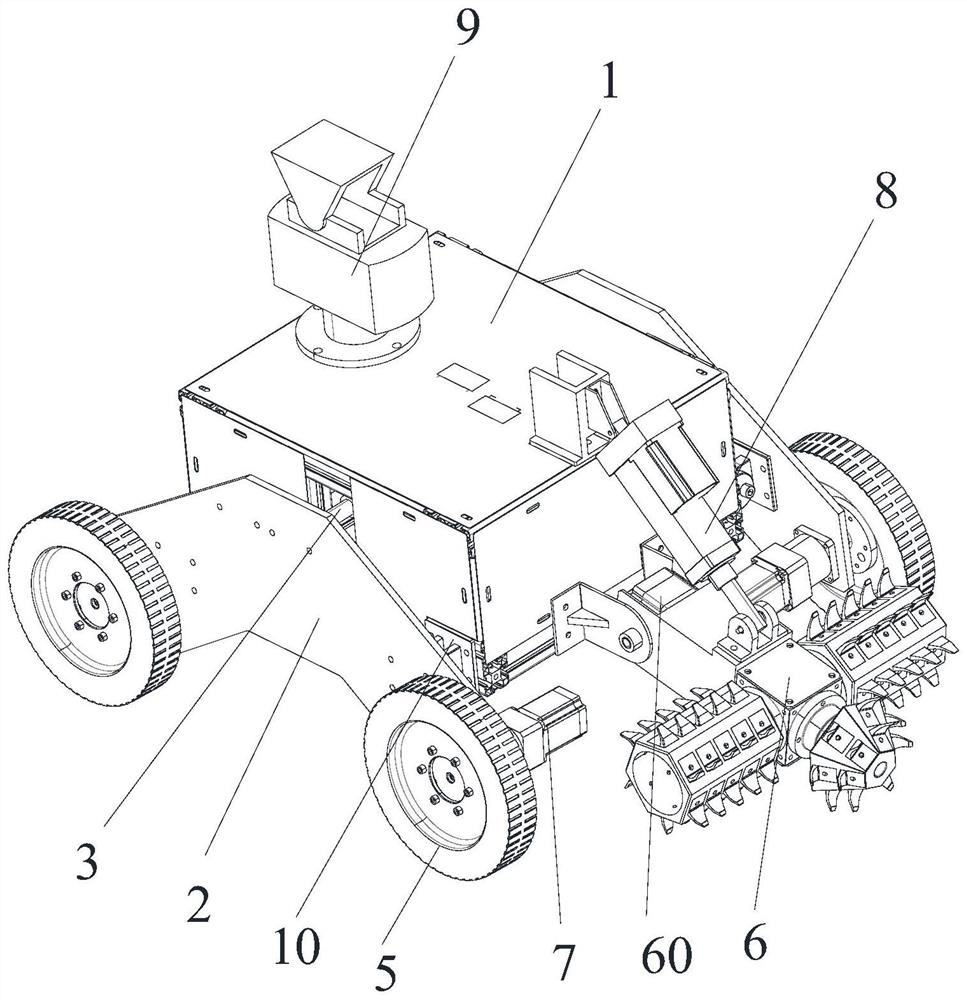

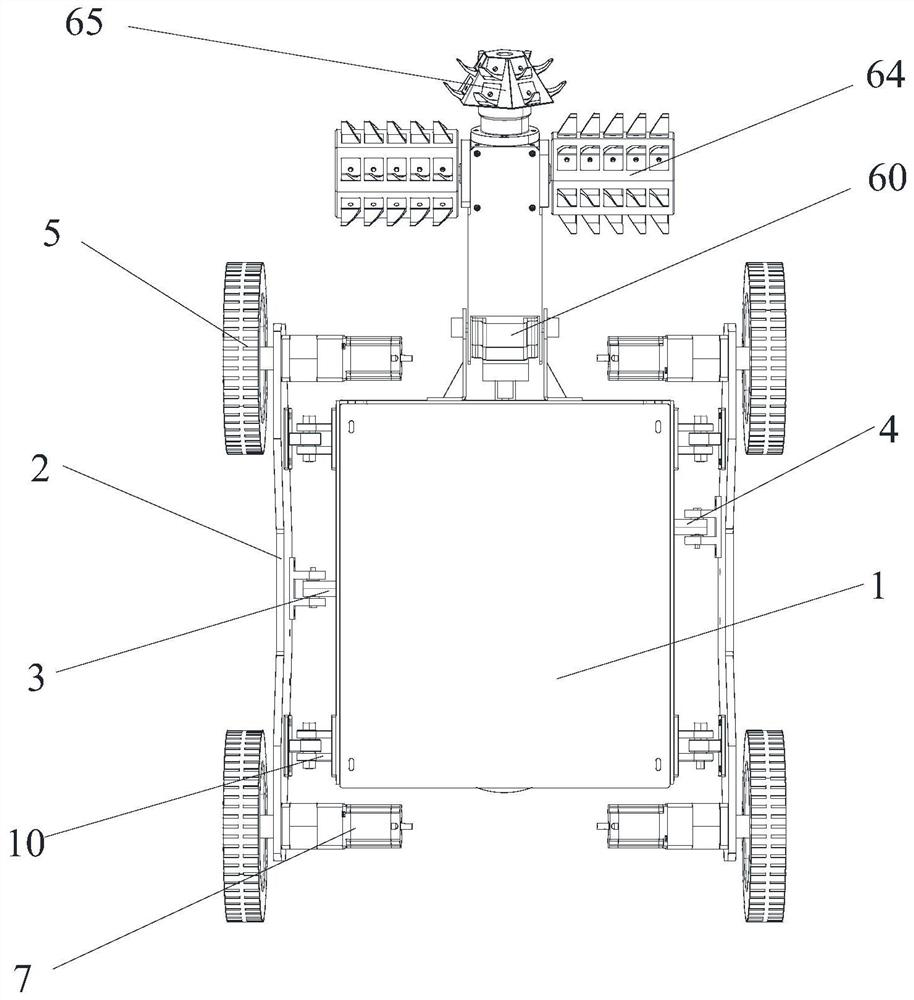

[0033] like Figure 1-6 The shown wheeled dredging robot of the present invention adopts a modular design, including: a drive module, a mechanical body module, a dredging and stirring module and an intelligent control module, wherein the mechanical body module is a frame box 1, and the interior of the frame box 1 It is used to install power battery and electrical control box, etc. The drive module includes: two wheel hub mounting plates 2 installed on the left and right sides of the frame box 1 and the wheel hub 5 installed on the wheel hub mounting plate 2. The frame box 1 is installed with The left electric push rod 3 and the right electric push rod 4, the telescopic end of the left electric push rod 3 is connected to the left wheel hub mounting plate 2, and the telescopic end of the right electric push rod 4 is connected to the right wheel hub mounting plate 2.

[0034] see figure 1 and figure 2 , the left and right sides of the frame box 1 are respectively installed wit...

Embodiment 2

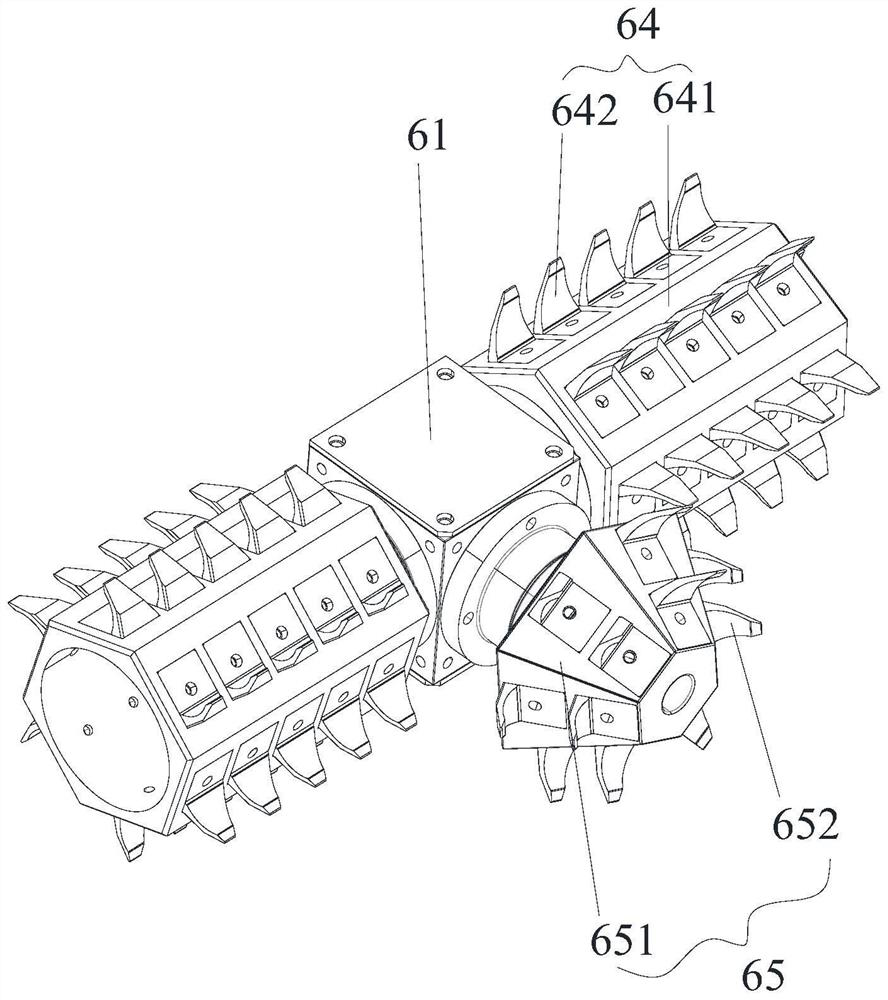

[0046] see Figure 7 , The difference from Embodiment 1 is that the gearbox 61 also has an upper output shaft 66 and a lower output shaft 67 , and a second stirring roller 65 is connected to the upper output shaft 66 and the lower output shaft 67 . An upper bevel gear 611 is meshed above the driving bevel gear 68 , a lower bevel gear 612 is meshed below the driving bevel gear 68 , the upper bevel gear 611 is mounted on the upper output shaft 66 , and the lower bevel gear 612 is mounted on the lower output shaft 67 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com