Electric wheel chock capable of automatically collecting time of wheel chock

An automatic collection, electric wheel technology, applied in the field of electric wheel block, can solve the problems of poor blocking effect, dangerous staff, low efficiency, etc., and achieve the effect of improving the guarantee operation efficiency, accurate wheel block time and reducing reaction time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in detail below with reference to the accompanying drawings and embodiments.

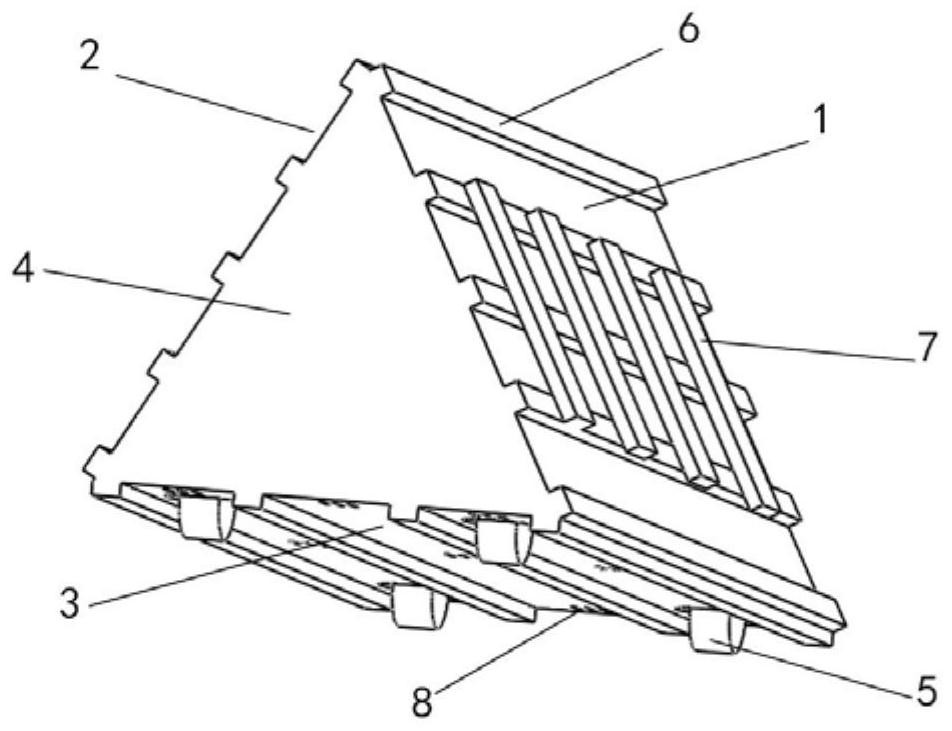

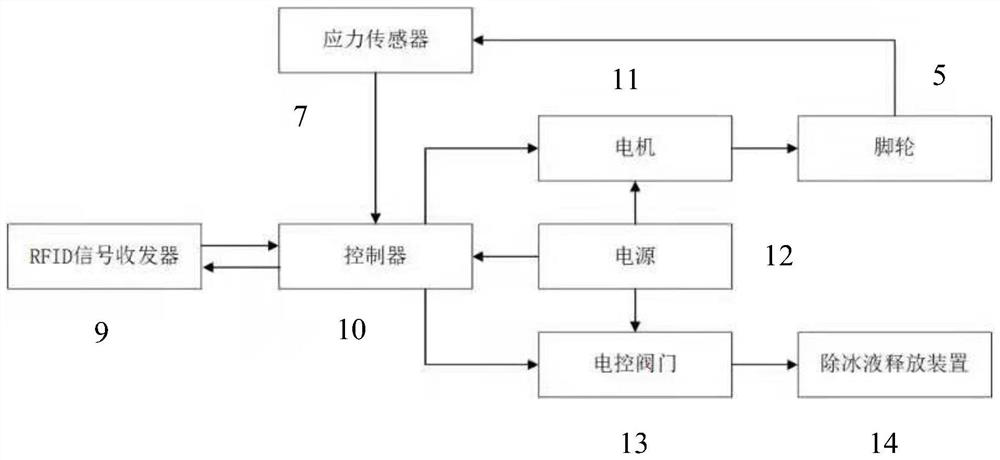

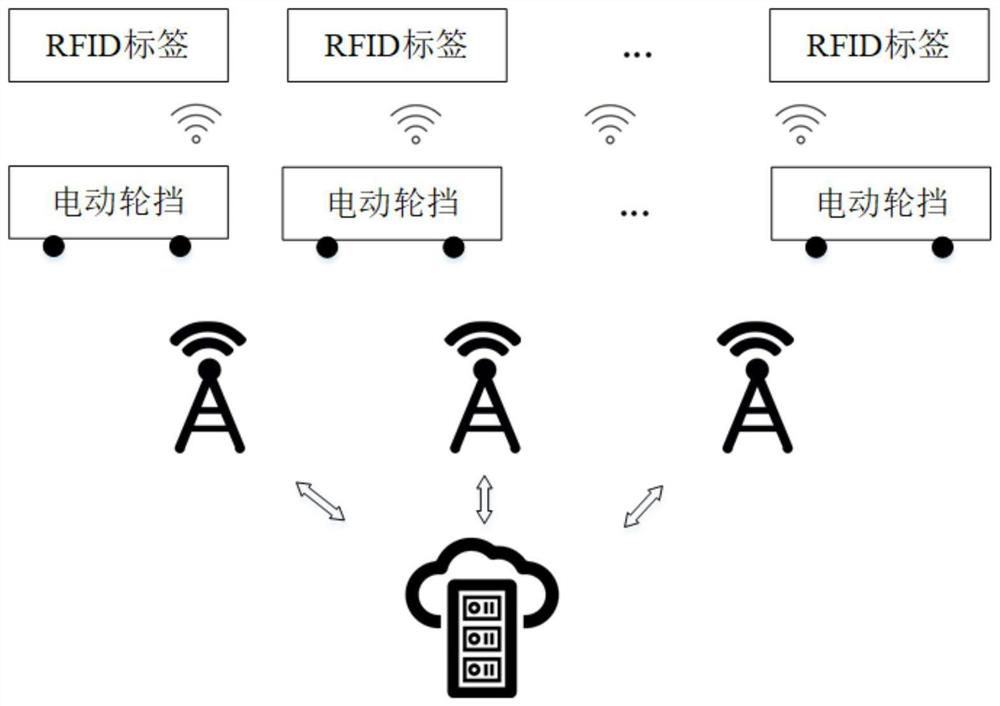

[0023] like figure 1 , figure 2 As shown, the electric wheel block provided by the present invention that can automatically collect the wheel block time includes a wheel block body, a control system, casters 5 and a deicing fluid release device 14; wherein the wheel block body is composed of a front baffle 1, a rear baffle 2 , The bottom plate 3 and two side plates 4 are formed, and the side plates 4 are hollow triangular prisms of equilateral triangles. The liquid hole 8, and a caster 5 is installed at the four corners of the bottom plate 3; the control system includes a stress sensor 7, an RFID signal transceiver 9, a controller 10, a motor 11, a power supply 12 and an electronically controlled valve 13; the stress sensor 7 is installed on the anti-skid The surface of the rubber strip 6; the RFID signal transceiver 9, the controller 10, the motor 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com