Automatic hinge assembling device

An automatic assembly and hinge technology, used in assembly machines, metal processing equipment, manufacturing tools, etc., can solve the problems of manual grasping, easy rolling, manual labor, etc., to achieve easy access, difficult to roll and fall, and high efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] In order to make the objects, technical solutions and advantages of the present invention clearer, the following will be combined with figure 1 - Figure 17 The present invention is described in further detail in the accompanying drawings.

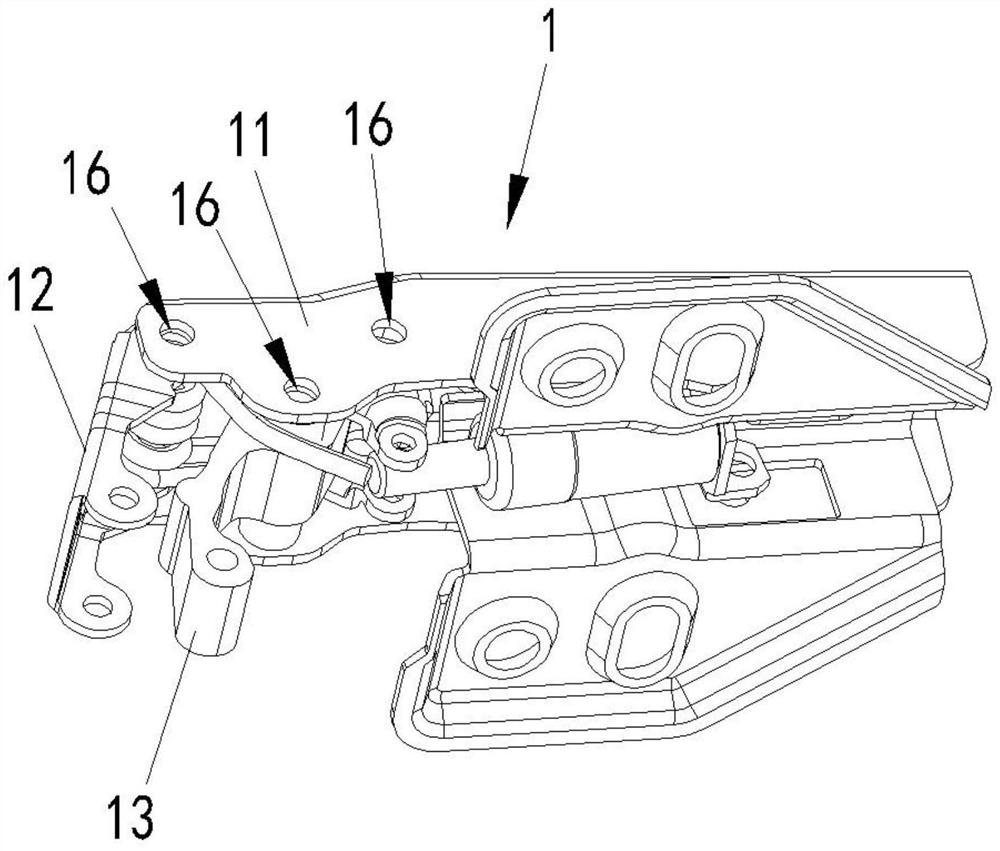

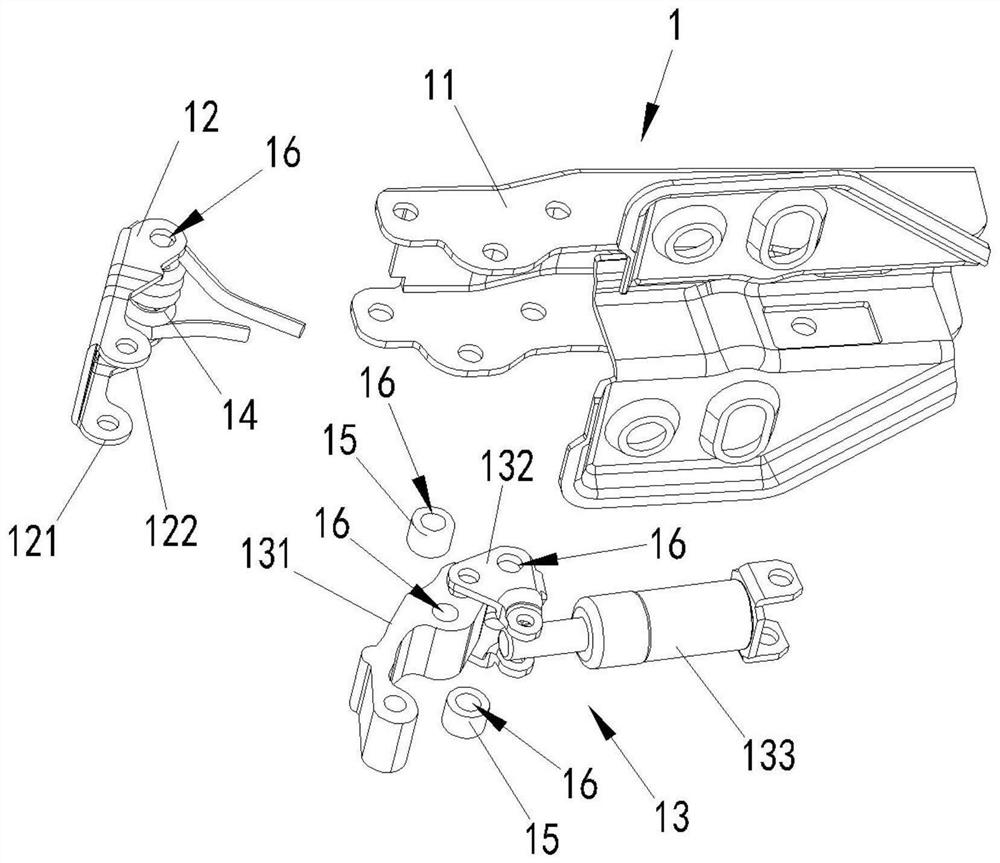

[0057] refer to figure 1 - figure 2 As shown, the existing hinge 1 includes an arm body 11, a four-hole piece 12, an inner strip assembly 13, a torsion spring 14, a plastic round tube 15 and other components, wherein the inner strip assembly 13 is composed of laminations 131, triangular pieces 132 and damping The pipes 133 are connected in sequence, and each component has connection holes 16 respectively. The connection holes 16 of each component are aligned with each other and the connecting nails are inserted to realize the assembly of the hinge.

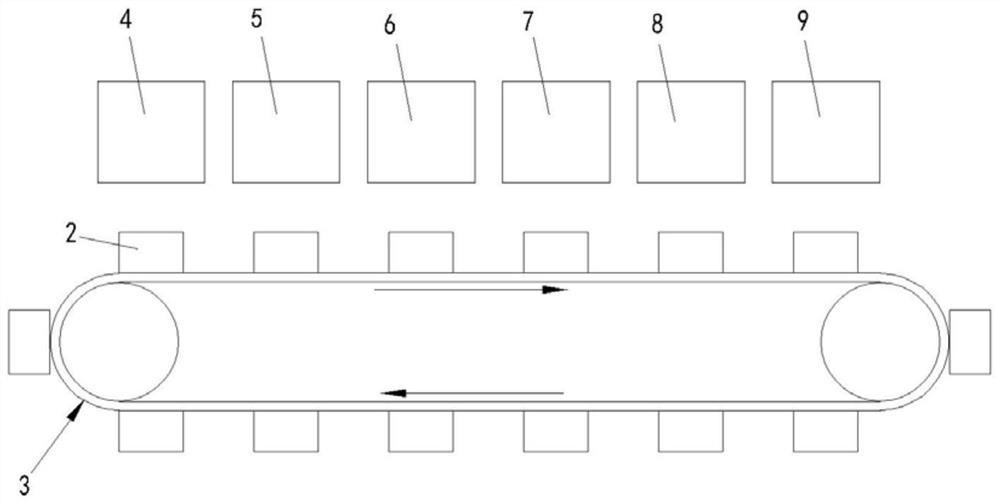

[0058] refer to image 3 As shown, this embodiment discloses an automatic hinge assembly device, including a carrier 2 and a conveying device 3. The conveying device 3 is a convent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com