Vehicle window glass lifting device

A technology for lifting devices and window glass, which is applied in door/window fittings, wing leaf control mechanisms, buildings, etc., can solve problems such as reel movement and abnormal noise, and achieve the purpose of avoiding slotting, improving connection stability, The effect of improving installation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

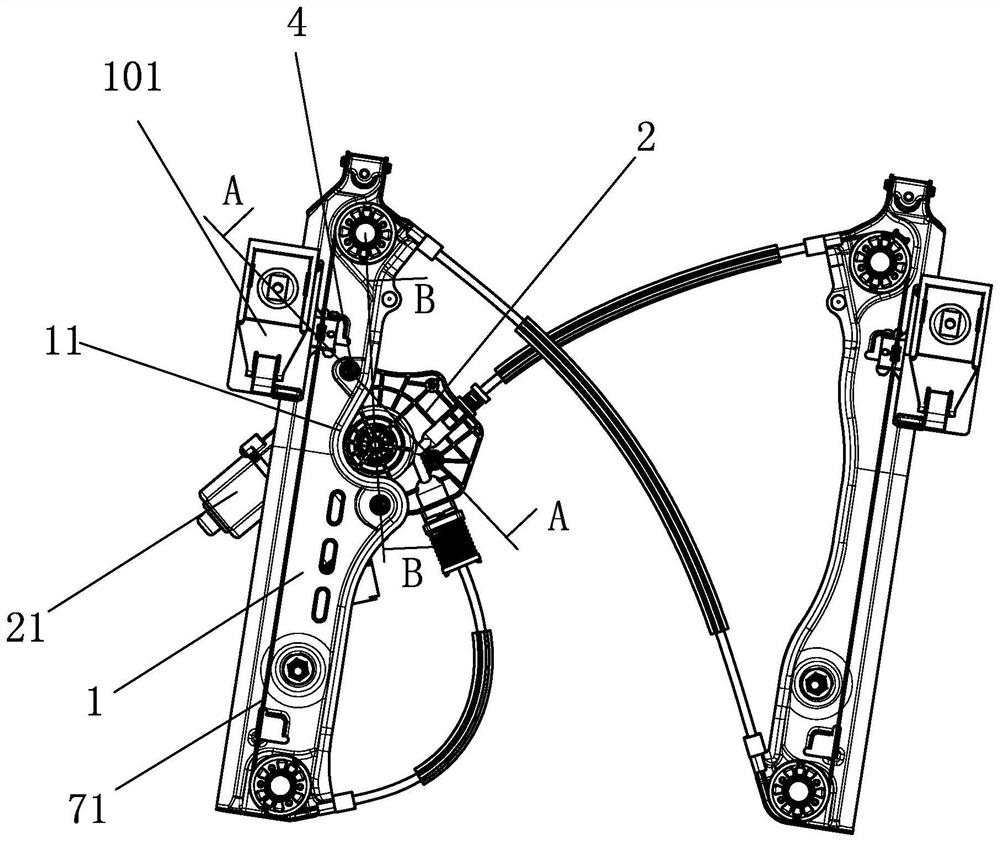

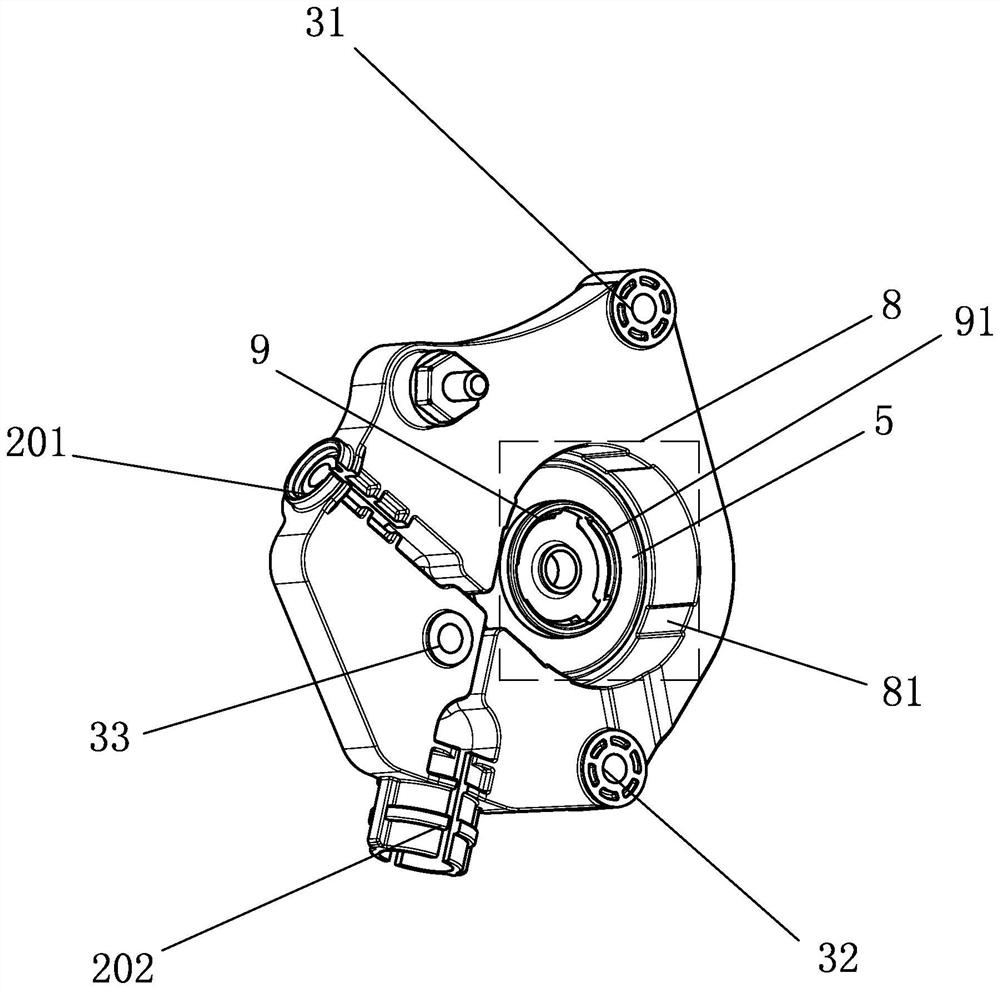

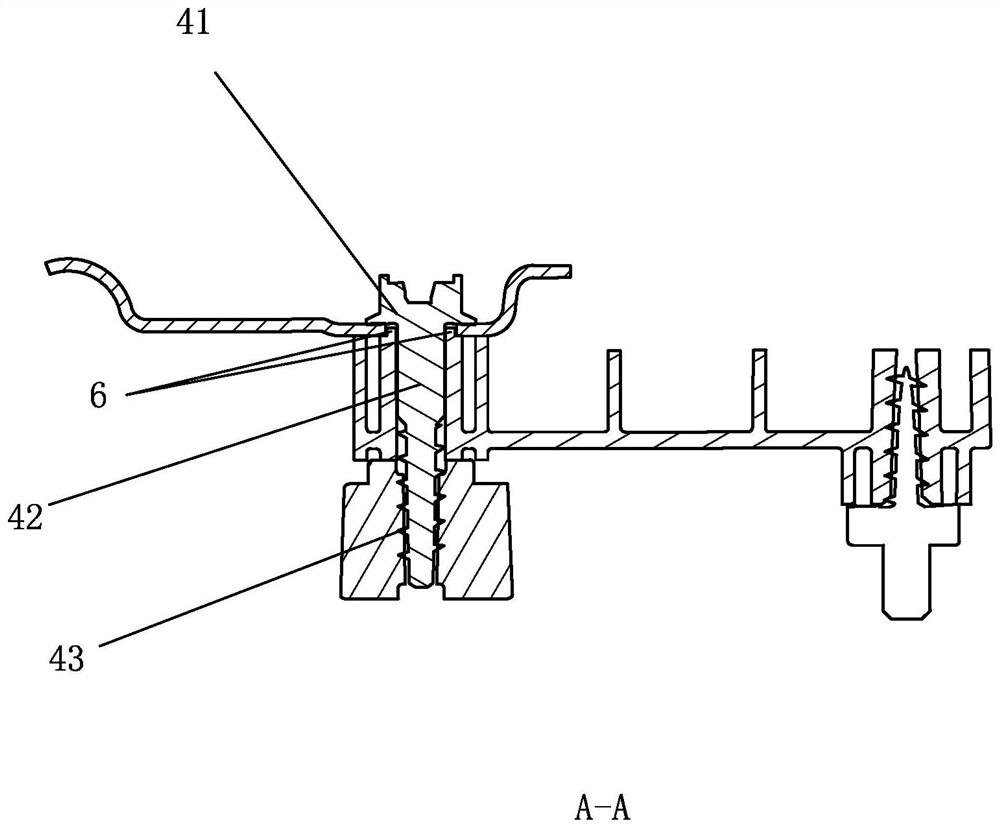

[0026] like figure 1 , shown in 2, a lifting device for vehicle window glass, comprising a guide rail 1, the guide rail 1 is provided with a motor base 2, the motor base 2 is provided with a fixing hole group 3, and the motor base 2 passes through the fixing holes The group 3 is connected with the guide rail 1, the fixing hole group 3 is provided with a connecting piece 4, the fixing hole group 3 includes a fixing hole 1 31 and a fixing hole 2 32, and the motor base 2 is also provided with a winding wheel The reel chamber 5 is located on the connecting line between the fixing hole 1 31 and the fixing hole 2 32 , and the outer wall of the reel chamber 5 is connected with the guide rail 1 . The guide rail 1 is provided with a concave assembly portion 11 , and the concave assembly portion 11 includes a relinquishment groove, and the relinquishment groove half surrounds the outer wall of the reel chamber 5 .

[0027] A motor 21 is installed on the motor base 2 , and the motor 21 ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com