Preparation method of retractable light mast, retractable light mast and sailboat

A mast and lightweight technology, applied in the field of sailing, can solve the problems of affecting the sailing stability and sailing efficiency, the heavy metal mast, and increasing the sailing quality, so as to achieve good application prospects, reduce the sailing center of gravity, and improve sailing efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

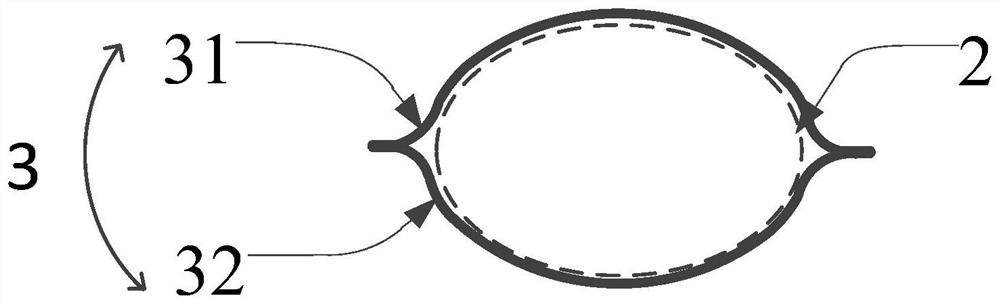

Image

Examples

Embodiment Construction

[0044] Where the word "embodiment" is used exclusively herein, any embodiment described as "exemplary" is not necessarily to be construed as preferred or advantageous over other embodiments. In the performance index test in the examples of this application, unless otherwise specified, conventional test methods in the field are used. It should be understood that the terms described in this application are only used to describe particular embodiments, and are not used to limit the content disclosed in this application.

[0045] Unless otherwise specified, the technical and scientific terms used herein have the same meaning as commonly understood by those of ordinary skill in the technical field to which this application belongs; as other test methods and technical means not specifically noted in this application, all refer to common sense in the art The experimental methods and technical means commonly used by technicians.

[0046] As used herein, the terms "substantially" and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com