Filter plate handle and filter plate of filter press

A filter plate and handle technology, which is applied in the field of filter plate handles and filter press filter plates, can solve the problem that the filter plate handle cannot be accurately aligned and installed, and achieve the effect of ensuring accurate alignment and installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

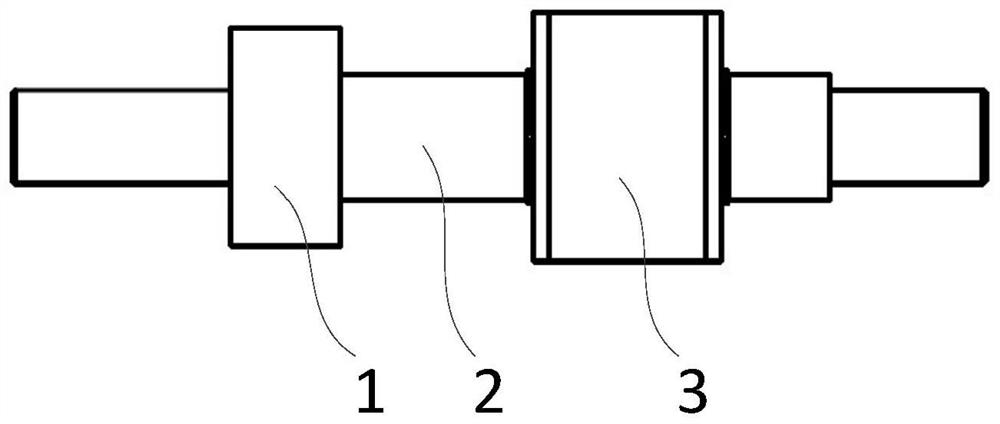

[0028] The core of the present invention is to provide a filter plate handle, which adopts double fixation to increase stability, and achieves precise alignment with waist interference fit.

[0029] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the filter plate handle of the present invention will be described in further detail below with reference to the accompanying drawings and specific embodiments.

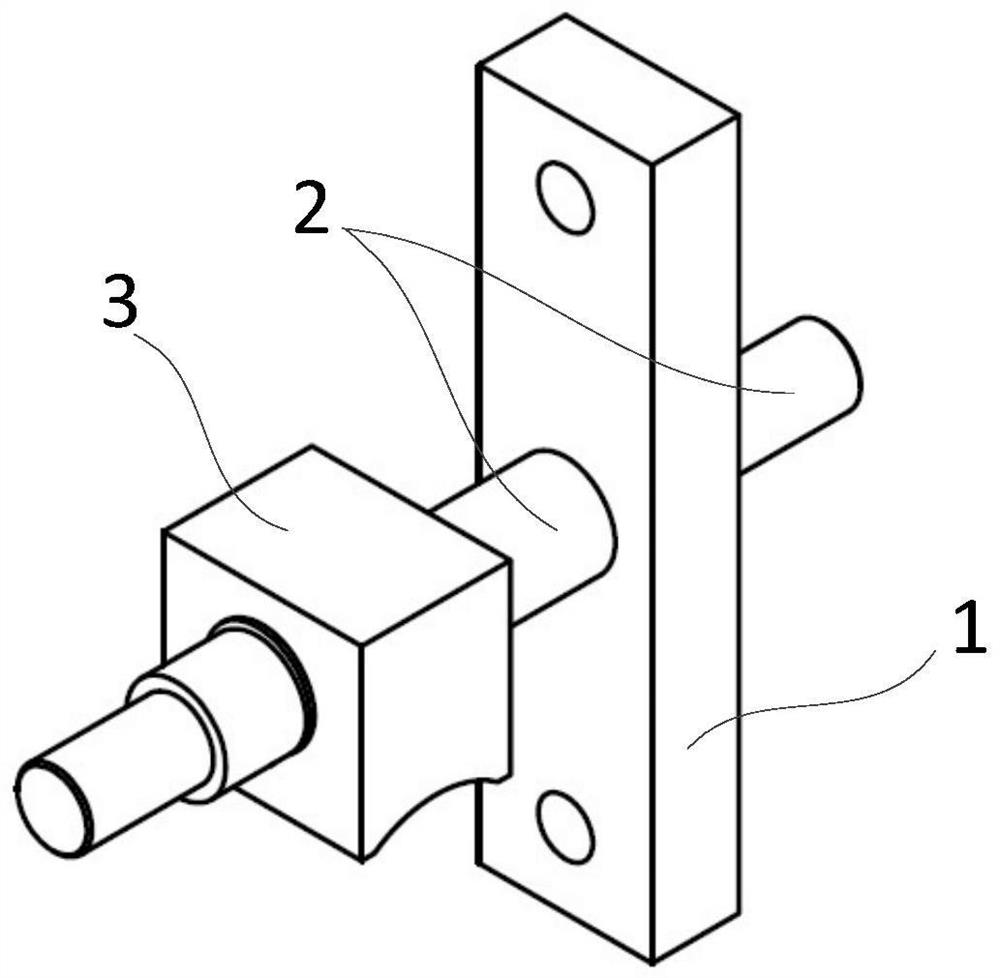

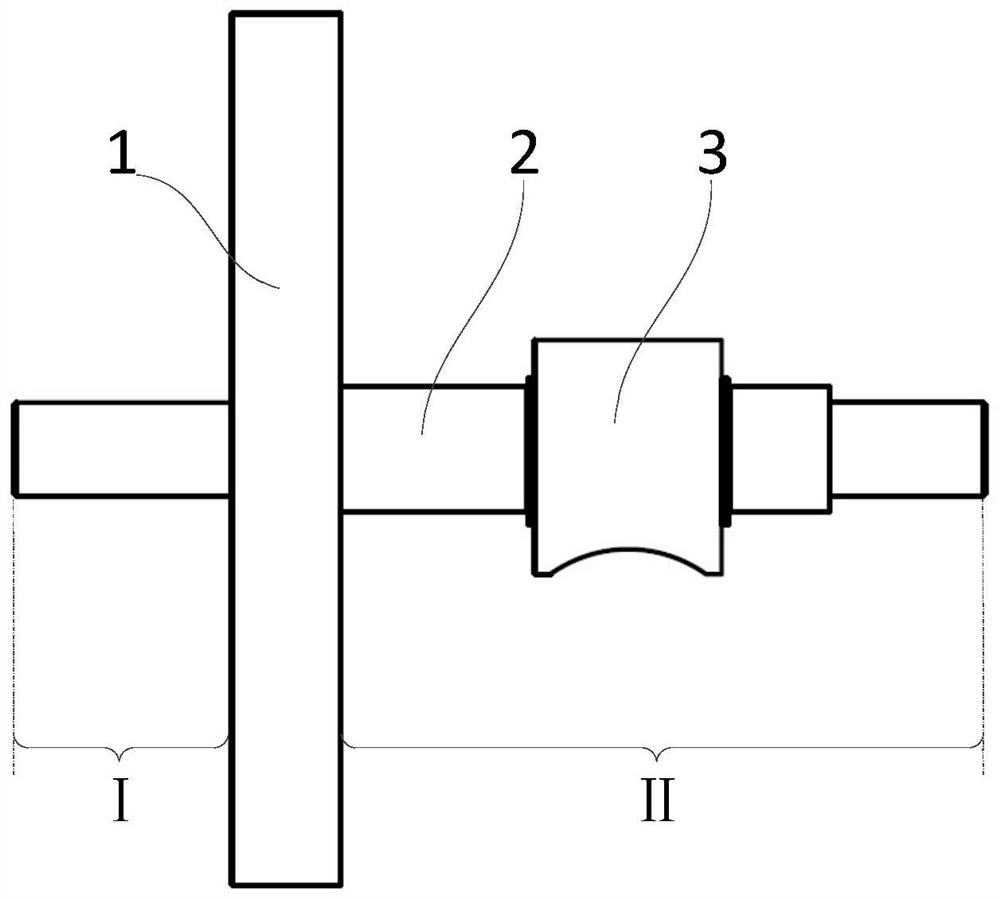

[0030] combine Figure 1 to Figure 5 , the present invention provides a filter plate handle, the filter plate handle includes a relatively fixed fixed plate 1 and a plug-in shaft 2, the fixed plate 1 and the plug-in shaft 2 are kept as a whole in the use state, and the two cannot be relative to each other. Shaking or staggering; the plug shaft 2 protrudes from the two sides of the fixed plate 1 respectively to form two protruding parts, which are used as the first section and the second section respectively; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com